The heart of medical technology beats on the southern edge of Baden-Württemberg. Around 40 kilometers northwest of Lake Constance lies the tranquil town of Tuttlingen. A Swabian district town with 35,000 inhabitants - while being a world center for medical technology. Around 600 companies manufacture surgical and medical technology products here. Aesculap, the oldest local medical technology company and part of the B. Braun medical technology group for many years, is based right next to the station.

But that is only half the truth. Aesculap manufactures at a total of 15 locations around the globe. They all supply products for the entire Group, but have different areas of focus. While the three plants in Tuttlingen produce surgical instruments, conventional and 3D-printed implants as well as sterile containers and motor systems, the Chinese plant in Suzhou, for example, also manufactures bone punches exclusively for the entire Aesculap Group in addition to forceps.

Tuttlingen acts as a “lead plant”, as Marc Laufer, Vice President Engineering at Aesculap in Tuttlingen, explains: “We are often the technology leader and develop processes further before rolling them out internationally.” This also applies to new manufacturing processes: When a new one is introduced, initial tests, qualifications and validations are carried out at the main site, then the other plants are provided with the systems, including the associated standards and parameters.

SWAP SHORT FOR ULTRASHORT PULSES

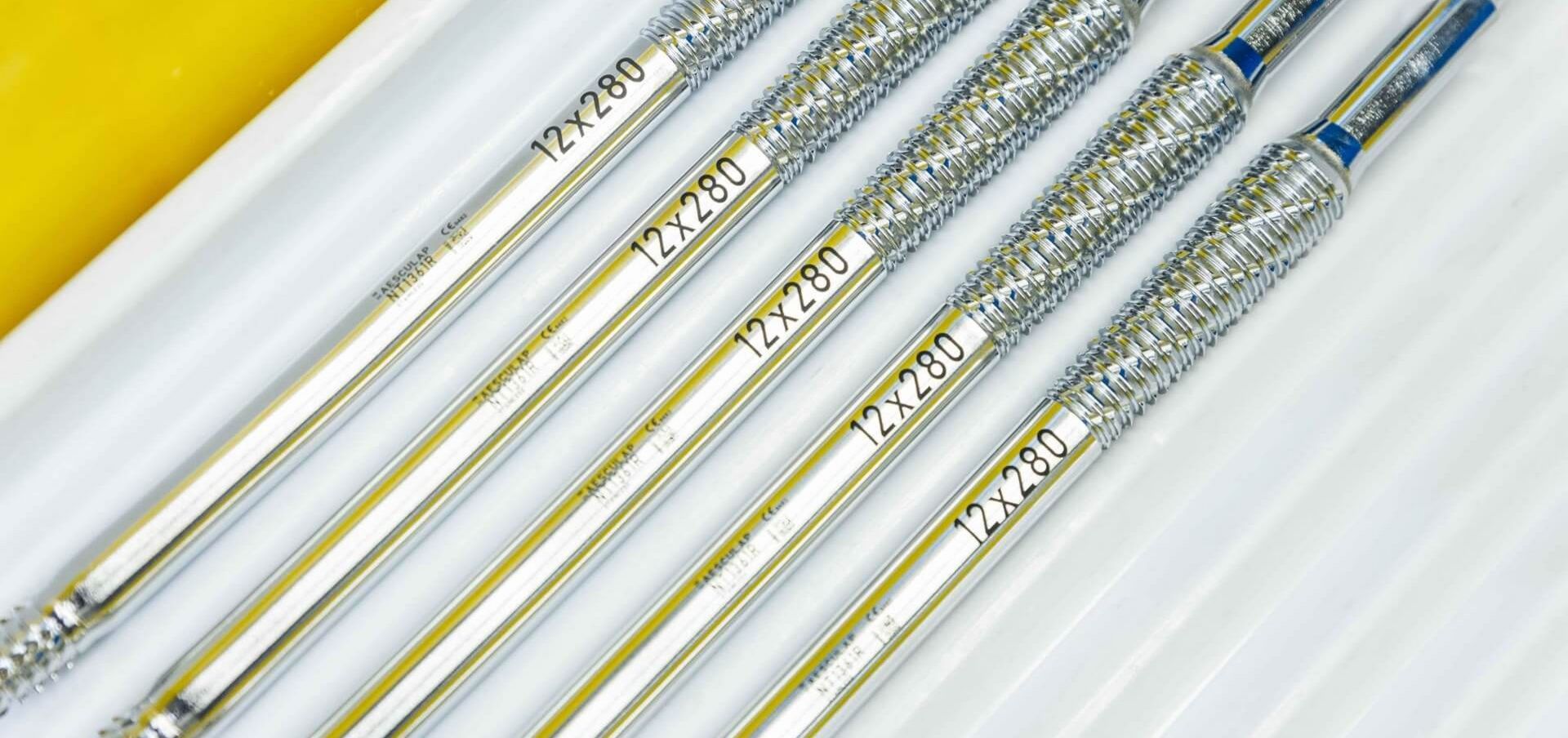

This is also currently the case with the introduction of the new TruMicro Mark ultrashort pulse laser. These will gradually replace all the short-pulse lasers previously used in Aesculap production facilities worldwide. With their ultrashort pulses, they provide the medical technology manufacturer with decisive advantages both during marking and during the subsequent cleaning process: The microstructuring allows Aesculap to apply more robust and durable markings.

This is because, unlike engraving, there is no oxide film that slowly dissolves over the frequent washing and sterilization cycles. Additionally, less combustion residue is produced during the production process. This eliminates the need for additional manual cleaning afterwards. Felix Schmidt, Head of Systems &Security, Production Digitalization at Aesculap in Tuttlingen, says: “The ultrashort pulse lasers allow us to work even more efficiently. They also offer constant laser power and consistent quality.”

A promising technology - and the replacement of all existing lasers with new systems is also a mammoth project. Laufer and Schmidt implemented this together with their teams and the users. For six months, they tested the processes on a test system with a TruMicro Mark 2030 from TRUMPF under production conditions and developed standards. Laufer says: “The biggest challenge was to reconcile the various requirements. We have an enormous variety of products, but at the same time highly varying quantities. This variety must then function smoothly on the systems, regardless of which plant in the world they are located in.”

In addition to numerous tests, the development process also includes visits to the Laser Application Center (LAC) at TRUMPF in Ditzingen: “We were able to carry out tests on various samples and materials with the TRUMPF experts there,” reports Schmidt. “We have now built up a very good level of expertise ourselves and usually test new materials in-house. But if we ever reach our limit or have a very special application, we always receive competent support at the LAC. This helps us a lot, especially when introducing a new technology.” Laufer adds: “Both sides benefit from this partnership-based cooperation. With new systems, not everything runs smoothly straight away. Through our feedback and working together on solutions, TRUMPF continues to develop - and so do we.”

QUICK HELP ON SITE

Felix Schmidt is convinced that the laser specialists in Ditzingen not only provide him with reliable technology, but also with equally reliable service. “TRUMPF is characterized by good support and high availability. No matter where we are in the world, help is always quickly on hand in the event of a fault. Our contacts are aware of the special features of our market and respond accordingly.”

This is particularly important for his colleague Charlie Zhu. Zhu is responsible for laser applications at the “China Instrument Plant” in Suzhou. A TruMark Station 7000 with a TruMicro Mark 2030 and two TruMark Station 5000 with TruMark 3000 lasers are in use there: “We mark over a million surgical instruments here every year, but sometimes in small and varying series sizes of ten to 200 pieces. This means we need reliable systems that also allow us to change quickly.”

Quite apart from machines that he can rely on, Zhu needs one thing above all: “Reliable service! We are a small site. If one of our systems breaks down, we lose a quarter of our production capacity.” He is therefore all the happier that his colleagues in Tuttlingen have opted for TRUMPF technology for years, and once again with the ultrashort pulse lasers. “The service from TRUMPF here in Suzhou is simply unbeatable. In the event of problems, we get help quickly by phone and online, so that we usually no longer need a service technician. Spare parts arrive at our premises within three hours by cab. Which means we can solve problems within a day.”

Even a mammoth project such as the changeover to a new laser technology in all plants worldwide is easier to manage with a partner like TRUMPF. Felix Schmidt knows why: “TRUMPF has a similar company philosophy to us - quality is at the heart of everything we do. As well as the ability to respond to customer requirements. We talk to each other as equals, exchange criticism and act accordingly. That's what makes this partnership so good.”