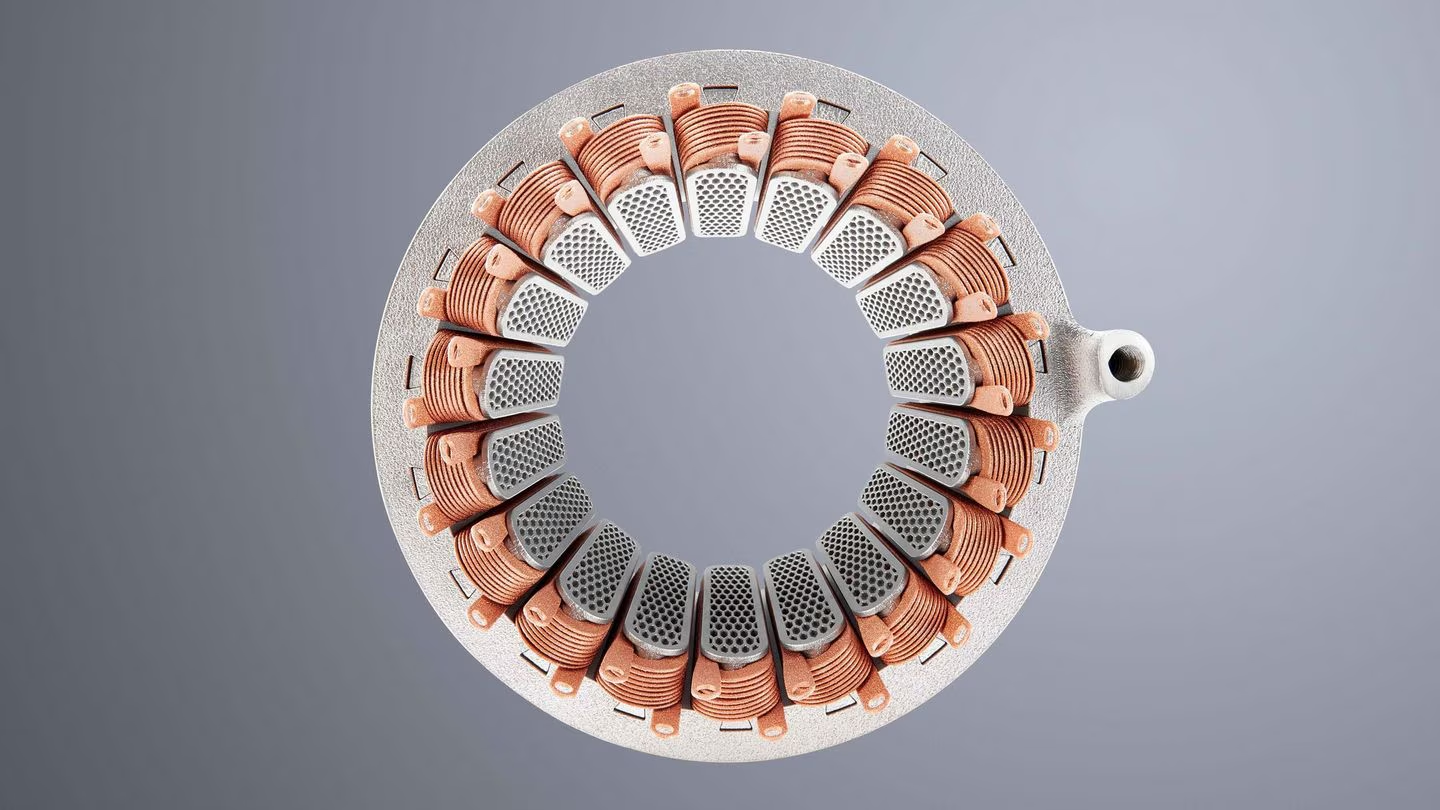

E-Drive Concept Demonstrator

The demonstrator shows the possibilities of additive manufacturing in combination with exceptional materials and AM design freedom. The copper coils are individually designed in each winding to increase the copper fill factor of the E-Drive and printed with the TruPrint 5000 Green Edition. The use of pure copper demonstrates excellent material properties such as> 100 % IACS electrical conductivity. The housing is made of aluminum (a typical ferromagnetic material), for example, and internally cooled to increase performance. The TruPrint systems print with a very high level of reproducibly. The simple change of production, for example from TruPrint 3000 to TruPrint 5000, is a great advantage for scaling production and reducing start-up costs. The 2x 700 W laser power means that the TruPrint 3000 can now print 220 cm³ aluminum parts per hour with two lasers. Thanks to the additional laser, the TruPrint 5000 achieves even higher values with consistent surface quality.

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures for an example part

Material: pure copper and AlSi10Mg housing

Conductivity: 101% IACS

Created by: TRUMPF