For laser welding, TRUMPF relies on high-quality, precise industrial robots. They are particularly low-maintenance and have been tried and tested thousands of times in industry.

The advantages of our robotic welding cells

Robotic welding with TRUMPF helps to solve welding challenges

A shortage of skilled workers and increasing quality requirements are major challenges faced by companies when it comes to welding. Robotic welding with TRUMPF is the solution: robots take over the standard welding jobs, which means fewer skilled welders are needed. The robot also produces with consistent quality. This leads to improved planning. There are other positive effects as well: Productivity increases and part costs can decrease.

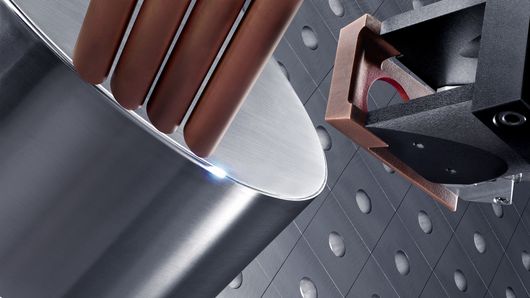

1. High-performance components

From the robot or cobot to the optics and welding source, everything is perfectly conceptualized and optimized for automated welding.

Find out more2. Incredibly simple programming

Programming is conveniently performed offline on the computer or by simple programming on the machine. In any case, the welding parameters are included.

Find out more3. Efficient operation parallel to production

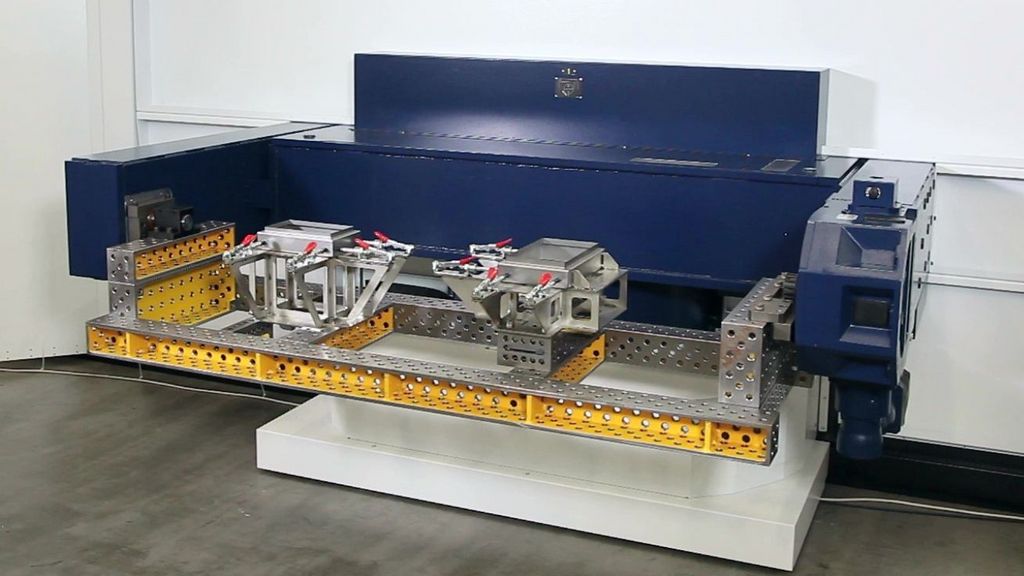

In two-station operation or with dual station tables and rotary tables, you set up the machine with the new part while it is welding with high productivity.

Back4. Fixtures - benefit from TRUMPF expertise

In workshops or seminars - which are completely free of charge in the WeldGuide anyway - you will learn everything you need to successfully perform automated welding.

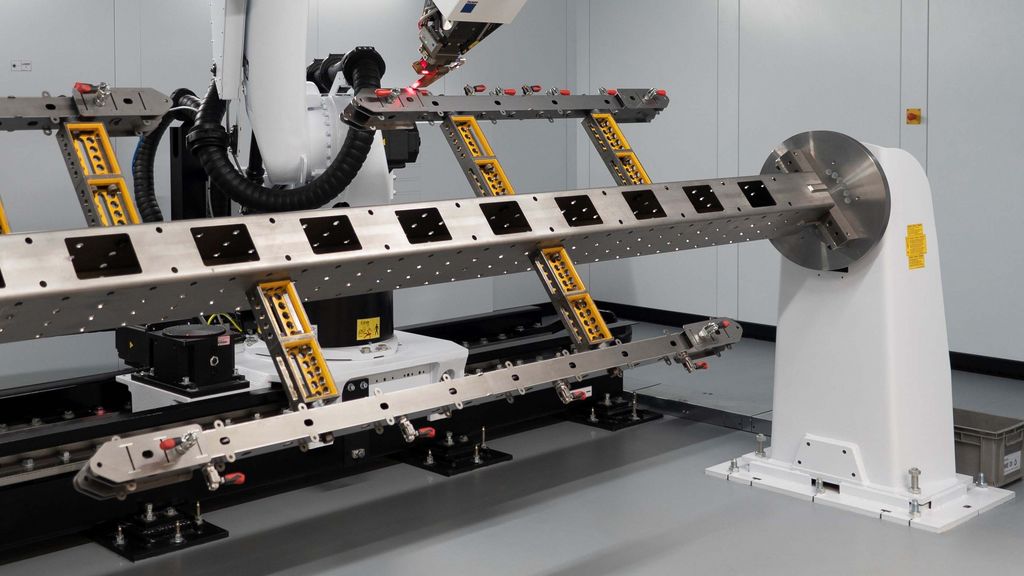

Find out more5. Accessibility – safely weld even complex and large components

With additional axes in the positioners and the rotary module on the optics, you can also weld components with difficult geometries in a tool setup.

Find out moreHigh-performance components - automated welding thanks to intelligent robotic and optics solutions

Incredibly simple programming

Efficient operation parallel to production

Fixtures - benefit from TRUMPF expertise

TRUMPF customers can learn the basic principles of fixture design in seminars or customized workshops. The focus is on fixtures made of sheet metal, as this is usually the more economical solution compared to other fixture concepts. For this purpose, cut sheets of metal are inserted into one another to form the main body of the fixture.

For small series, you can also use standard clamping systems to build a fixture. This is economical because the clamping elements can be reused several times. The fastening is easy via the work table with standard D16 hole pattern in 50 x 50 mm scale.

For very small piece counts, investing in a separate fixture is often not worthwhile. It is also not necessary. For small piece counts, you can tack components and use simple clamps as a stop.

In the WeldGuide you will find exclusive tips on the topic of fixtures and numerous practical examples. This allows you to make even better use of your TRUMPF robotic welding cell and perhaps discover new possibilities for future orders.