- Step 1: Load your component in TruTops Weld and select the areas you want to weld.

- Step 2: Next, select the appropriate welding parameters for your desired result.

- Step 3: Now, virtually place the component onto the component positioner with the fixture and detect possible collision points.

- Step 4: Apply the optimized program to the TruLaser Weld 5000. The TeachLine sensor solution detects the exact position of the component on the machine and adapts the program automatically. This helps reduce time-consuming reteaching. Alternatively, you can reteach the program conventionally.

You can create programs while the machine is operating

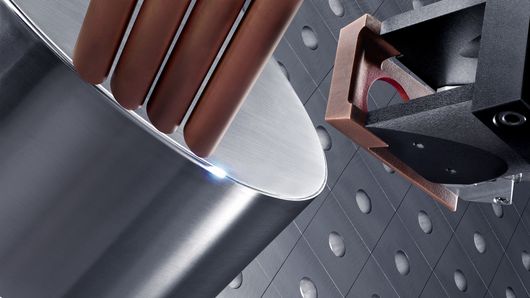

Create your welding program quickly and easily: Reduce non-productive time on the TruLaser Weld 5000 with TruTops Weld, as the program is complied offline on the computer. Benefit from the offline programming from established TRUMPF technology expertise: TruTops Weld includes geometry parameters as well as welding parameters for heat conduction welding, deep penetration welding, BrightLine Scan and FusionLine. In addition, many helpful machine functions such as rotary module, TeachLine or FusionLine are already integrated. From the offline program to the sensor system to the machine - the software has been optimized for easy and fast programming.

TRUMPF technology expertise and sophisticated functions make your work easier.

You create the program offline on the computer while your machine is welding.

Programming on the computer, producing on the machine – engage your employees according to their strengths.

You are more productive in your manufacturing, as programming is faster and does not block the machine.

TruTops Weld helps you to test complex components virtually and to find possible solutions.

From CAD model to welding program in just four steps