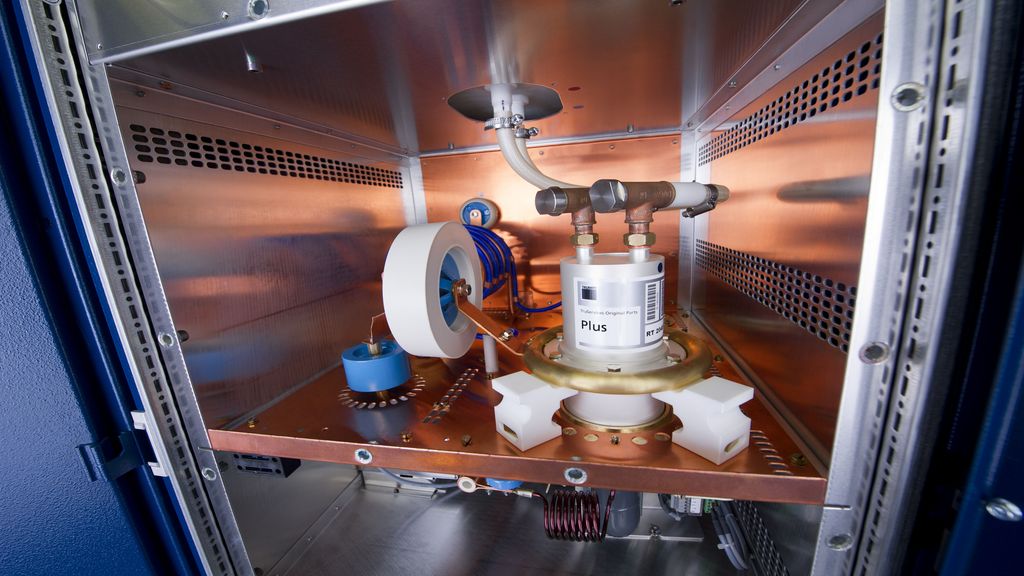

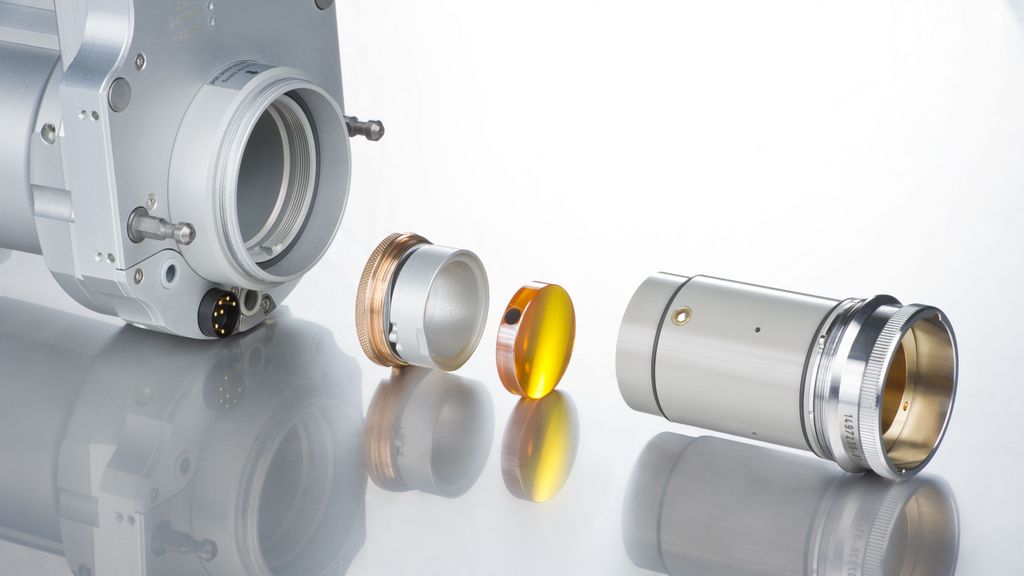

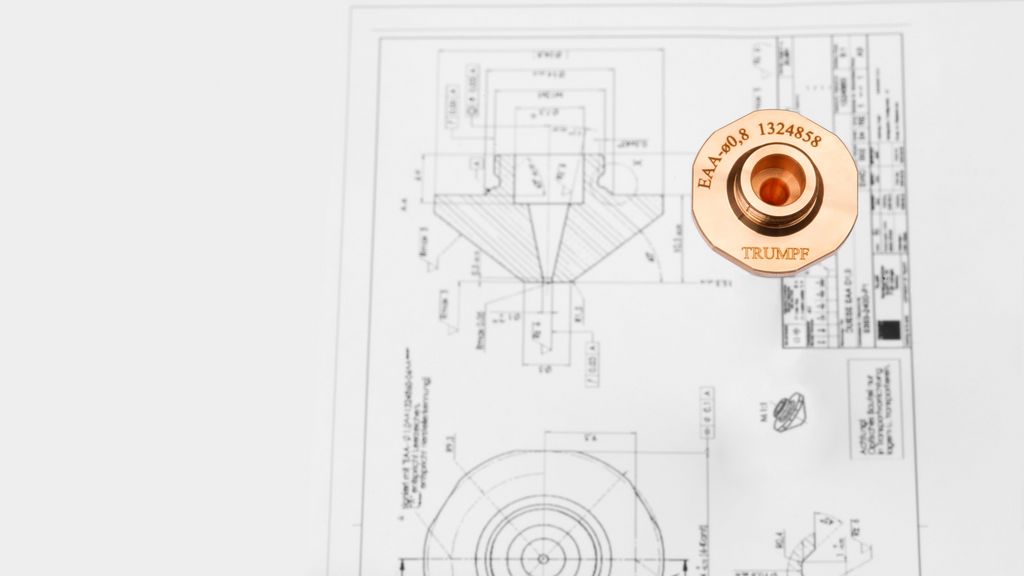

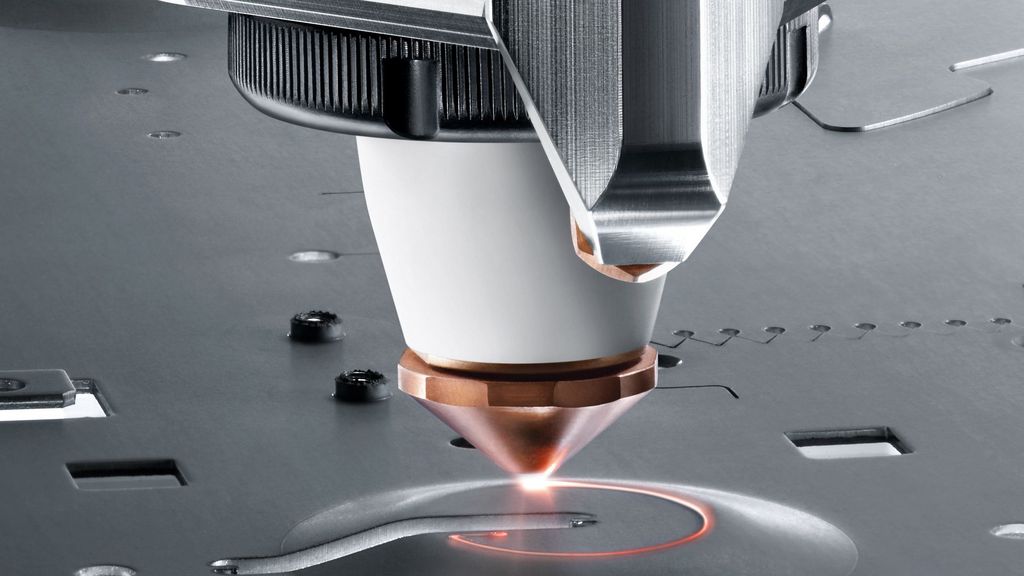

When it comes to quality, you should leave nothing to chance. Even during their development, spare parts, machines, lasers, and laser systems from TRUMPF are coordinated with each other to the finest detail. This allows us to not just achieve high process reliability, but also to offer spare parts that function according to the plug & play principle and require no adjustment whatsoever. So that it remains like this, TRUMPF ensures the highest quality standards.

Your investment should pay off in the long term. Spare parts from TRUMPF - also called Genuine Parts - help with this. The reason: With spare parts specifically designed for your product, you are guaranteed to produce parts more safely, reliably, and productively.

An overview of your benefits

Perfectly matched to your TRUMPF machine right from the get-go, our spare parts ensure your performance and productivity are maximized over the long term.

At TRUMPF, you can get the spare part you need at any time and as quickly as possible, no matter where your production is.

Should a replacement be necessary, we guarantee the quality of our products with "Xchange" beyond the warranty.

Our expertise gives you the competitive edge. Our experts are always ready to provide you with advice and support from ordering to installation and maintenance.

The low adjustment effort minimizes the idle times of your machine.