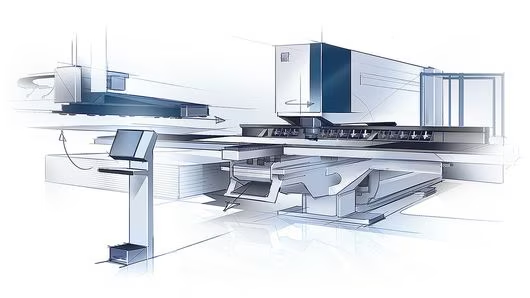

Punching machines

Maximum variety, minimum effort: the TRUMPF punching machine portfolio produces flexibly - with forming functions, threads and short non-productive times. A wide variety of sheet metal parts are produced with high productivity and consistent quality. From entry-level to automated large-scale production: each machine offers an optimum ratio of performance, economy and space - and sets standards in reliability, integration and user-friendliness.

At a glance: what benefits do our punching machines offer you?

You can manufacture complete parts on a TRUMPF punching machine. The technology is versatile due to the abundance of punching tools. Find out more about this here.

Contact

Services