Best possible loading and unloading, sorting and packing on pallets

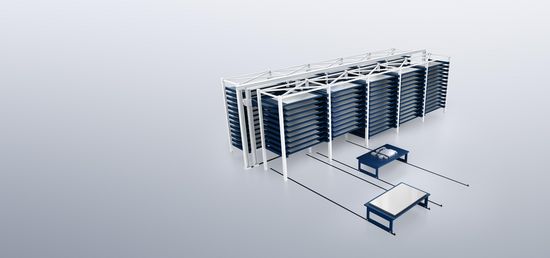

The new SheetMaster automatically and reliably loads and unloads your punching machine or punch laser machine. It also sorts your finished parts and packs them on pallets. The separation station further increases the loading speed, as the raw sheets are pre-separated while the SheetMaster is still unloading parts. Individually selectable suction cups simplify removal. The SheetMaster uses the additional sorting axis to position your finished parts flexibly to save space. You can extend and connect your SheetMaster with additional components.

The SheetMaster can easily remove sheet metal up to 6.4 mm and with the additional suction cup package this increases to 8 mm with a carrying capacity of 300 kg.

The SheetMaster can quickly and safely remove heavy and small parts. It can flexibly manage the palletizing process and stacking between stacks.

The SheetMaster also works reliably and fully automatically during shifts where there is little or no personnel.

The GripMaster automatically disposes of scrap skeletons, remainder strips, and microjoint sheets.

Expand the SheetMaster with TruStore store, STOPA store, and various cart systems.

The simultaneous pre-separation of raw sheets and deposit of finished parts increases the speed.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.