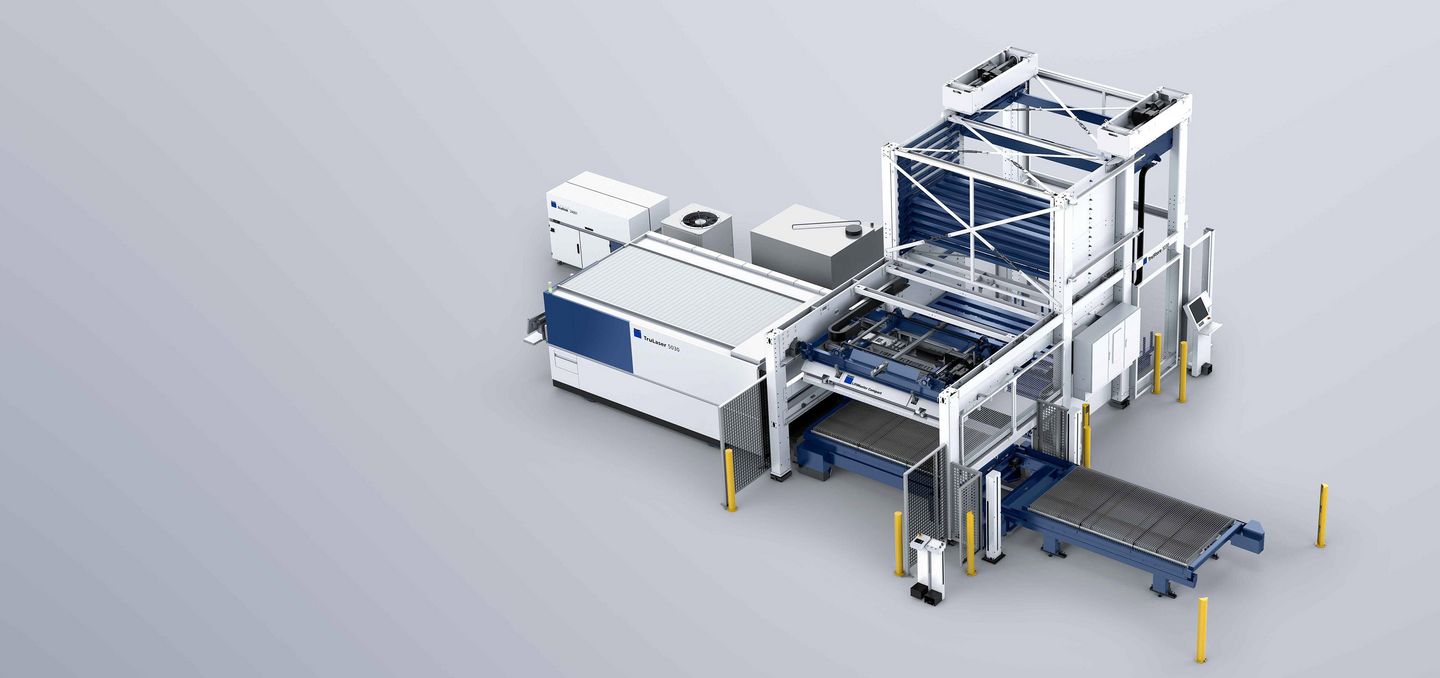

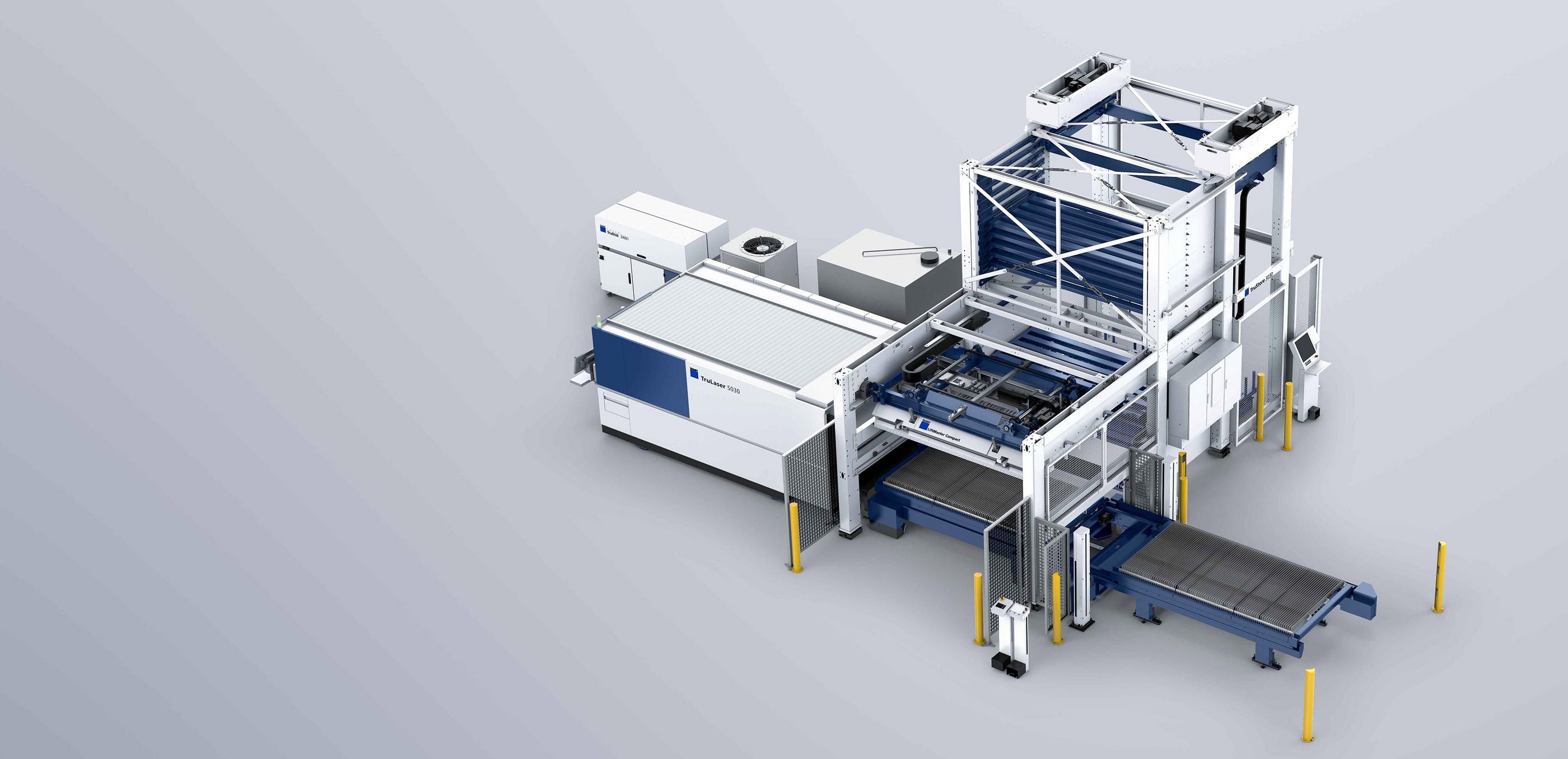

The key to uninterrupted production

With the third pallet station, you can add a crucial component to your TruLaser machines: Use the additional pallet position as a buffer to avoid production interruptions and optimize the material flow. Whether manual loading or fully automated, the third pallet station adapts to your requirements and significantly increases your flexibility. It really comes into its own with thick sheets: Loaded automatically, it can handle materials that exceed the usual automation limits. This keeps your processes continuous and efficient - even under the most demanding conditions.

Whether manual or automated loading - the station offers you full flexibility and accessibility.

The third pallet station minimizes downtimes and keeps your production running. This allows you to change or clean support strips in parallel - without interruption.

With the third pallet position and LiftMaster Compact, you can also handle thick materials safely and efficiently.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.