One in every thousand babies is born with hydrocephalus, or fluid on the brain, a condition in which too much cerebrospinal fluid (CSF) builds up within the brain ventricles. It causes a wide range of symptoms from early on in life, including headaches and frequent vomiting. Hydrocephalus is incurable but treatable, and an implant can significantly improve patients’ quality of life. Miethke – a high-tech medical device company based in Potsdam, Germany – manufactures the hydrocephalus valves, or shunts, that drain excess cerebrospinal fluid from the brain to return CSF pressure to normal. But the idea of inserting a medical device in a child’s body can still seem startling to some people. “Obviously you have to work at the very highest standards – and it takes a lot of laser technology to meet those standards while still keeping the process economically viable,” says Christian Gleumes, a project manager in Miethke’s research and development department. “We have our own lasers, but some of the bought-in parts we use are also produced using laser light.”

Working with suppliers hasn’t always been easy, however. “Our hydrocephalus valves are about ten millimeters long and four millimeters in diameter, and some of them contain a delicate, flat spring made of ultra-thin titanium foil that is just 0.05 millimeters thick. Obviously that has to be cold formed, in this case with ultrashort pulse (USP) lasers.” But the supplier that Miethke chose to do this job had a tough time adapting to the new methods and took too long to deliver the part. “We got fed up waiting, so we decided to bring the technology in-house and do it ourselves,” says Gleumes.

Cutting today, marking tomorrow

A few weeks later, on a visit to TRUMPF’s Laser Application Center, he took the TRUMPF engineers by surprise when he suggested cutting the foil with a marking laser instead of a beam source designed for cutting. The TruMicro Mark is the first TRUMPF laser to use ultrashort pulses for marking – but at that point it wasn’t even commercially available. “Obviously there are more economical machines for precision cutting than a marking laser,” says Gleumes. “But the idea was that it could boost redundancy by acting as a backup in case our main marking laser ever broke down.” Right now, Miethke uses just one nanopulse laser to mark its medical devices. “That’s a potential bottleneck. If it goes offline, everything grinds to a halt.” Hence the advantage of having a second laser waiting in the wings.

Tests by the TRUMPF application lab on precision cutting with the USP marking laser were successful – and Miethke was promptly signed up as a test customer for the TruMicro Mark. “We only produce small batches in this specialist segment of our business, so we weren’t using the ultrashort pulse laser to its full capacity. We wondered what else we could do with the machine since it was already there – and of course we realized the most logical step was to use the marking laser for marking!”

The most akward part

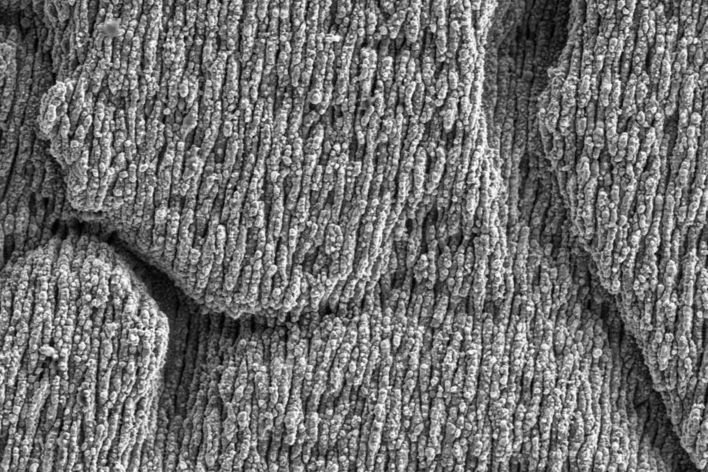

It didn’t take long to find the perfect candidate for marking: the small hydrocephalus valve itself. The valve marking is subject to strict UDI requirements: it must be corrosion resistant, readable by humans and machines alike throughout the lifetime of the device and biocompatible with zero contaminants in the material. “It’s a small part made of grade 5 titanium,” says Gleumes. “It has a polished, reflective surface that is also rounded, so it’s pretty much the worst-case scenario for a marking process!” Back in the TRUMPF application lab, engineers from the two companies came up with a process to tackle this challenging component. The USP laser produces what is known as a black marking – a nanopatterned surface structure that absorbs and scatters rays of light, creating an extremely dark, matt appearance without ablating any material.

“I was very impressed with the results,” says Gleumes. “The marking is perfectly readable in any light, whatever angle you look at it from.” This process leaves the metallic structure of the titanium surface virtually unchanged while maintaining full biocompatibility.

The outstanding quality of the marking gave Gleumes another idea. At that time, Miethke was using an engraving process to apply markings to the tools physicians use to adjust the company’s hydrocephalus valves: “You could feel the engraving when you touched it, and it didn’t look that great. Yet those are the parts that physicians, our customers, handle on a regular basis! A perfect design is a sign of quality, and that’s something we believe in very strongly.” The tools are made of anodized aluminum, and the tests with black marking proved to be equally successful in this case. “Deep black lettering that you can’t even feel. The new marking is really something! It looks just as good in the muted lighting of the chief physician’s office as it does in a brightly lit operating room.”

And how about …?

With three successful innovations already under his belt, Gleumes was inspired to come up with yet another idea. Miethke also makes parts from sapphire. The company’s existing laser machine couldn’t mark that material, so they had resorted to using stickers. “We kept having problems with bubbles of air getting trapped under the sticker. We tried our luck with the USP marking laser and the results were outstanding,” says Gleumes, explaining how they were able to eliminate the stickers for new products.

His next idea delved even deeper into the company’s range of products. One of Miethke’s products is equipped with electronics that are protected by a polymer screen cut from polyether ether ketone (PEEK). “The machining process was really tough because the material is so hard to cut,” says Gleumes. “What’s more, we would have preferred the screen to have been made from ceramic, an inert material that is better suited to this particular application. We also wanted to make the ceramic screens in-house so that we wouldn’t have to depend on a supplier.” So Gleumes began experimenting with ways of cutting thin aluminum oxide ceramic with the USP laser. “It worked perfectly. And the best thing is that we can apply three-dimensional structures to the surface that protect the implant electronics even more effectively,” says Gleumes.

That sparked his interest in the whole issue of surfaces. “Right now we’re experimenting with ways of using the laser to create hydrophobic and hydrophilic surfaces on our parts. It seems that once you get hold of an ultrashort pulse laser, you are constantly finding new things you can do with it!”