Stopping mid-sentence, Isidro Lobo turns round to looks for something. He has just been asked about the values that his company embodies. Moments later, the Managing Director of chiller cabinet manufacturer Jordão is back in the room again, picking up where he left off with a smile on his face. He holds up a small sign listing the company's values: positive attitude, ambition, team spirit, integrity and excellence. In addition, there is the company mission: "Creating the best solutions for food storage and presentation. Turning challenges into solutions. Respecting the environment." Every new employee is given the sign when they join the company. Lobo is keen to highlight one key point: Jordão not only promotes its values but also embodies them from the very first day an employee joins the company.

José Júlio Jordão founded the company in 1982 in Guimarães in northern Portugal. It all started with just 22 employees. Since then, the workforce has grown more than tenfold to 250 employees. Jordão is now one of Europe's leading manufacturers of standard and bespoke chiller cabinets for the food retail and hospitality sectors, serving well-known customers all over the world, with a turnover of 21.5 million euros.

Jordão is synonymous with innovation blending technology and sustainability. The company supplies digital, efficient and environmentally friendly solutions that help customers to reduce their energy consumption while presenting their food. Last autumn, one of its products even won an innovation award at a leading global trade fair for the catering and hotel industry.

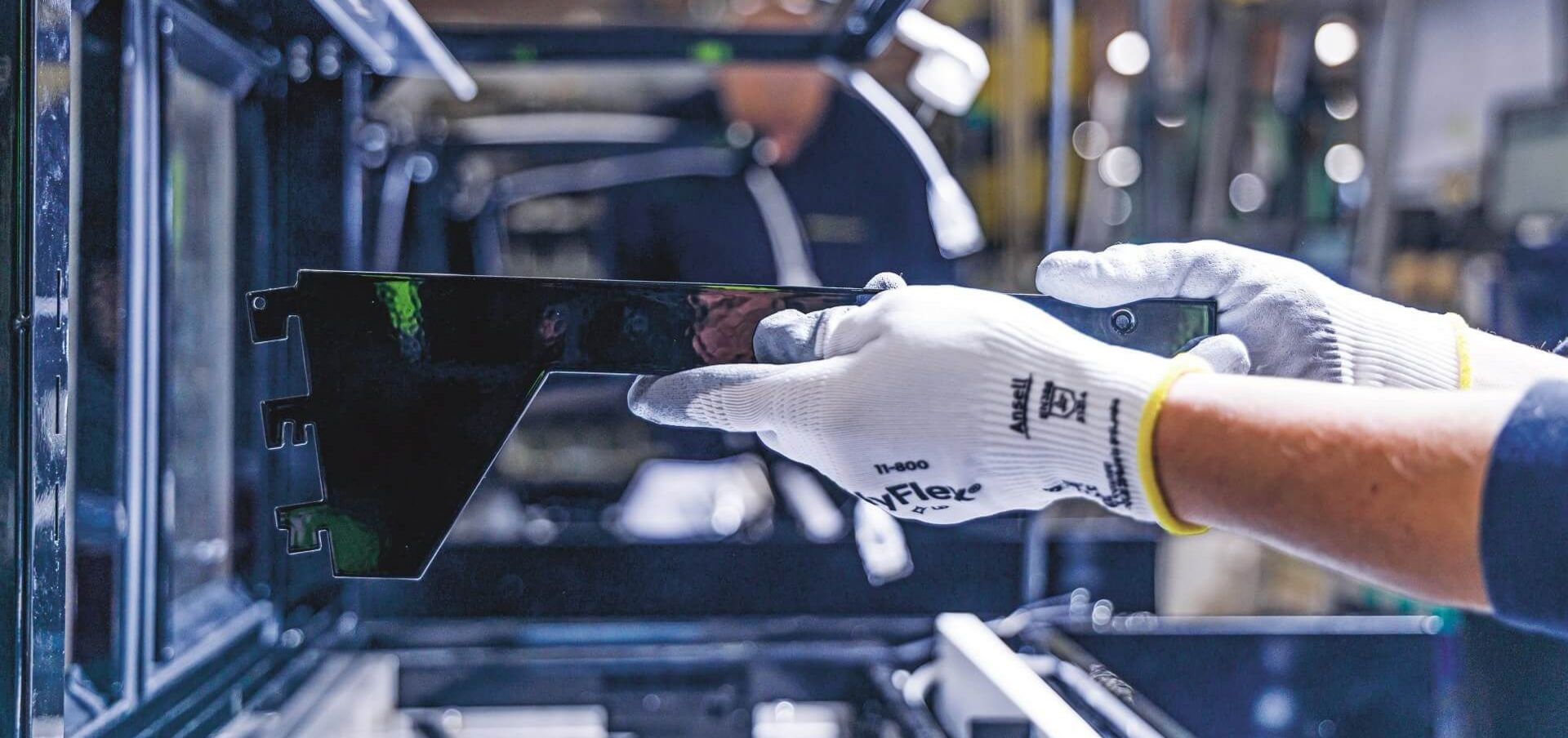

In 2021, the company entered into a partnership with TRUMPF. Jordão was looking for a machine to automatically bend small metal parts for chiller counters more quickly. TRUMPF was able to offer the perfect solution with the TruBend Cell 7000. The partners share not only business interests but also have common ground as family-run enterprises and innovators. This laid the foundation for a long-term working relationship. Jordão purchased more equipment – the TruLaser 3040 fibre 2D laser cutting machine and the TruStore compact storage system. When combined with the LiftMaster Compact and Part Master, the system fully automates parts cutting on the refrigerator manufacturer's production line.

Jordão values the TruBend Cell 7000 and the TruLaser 3040 for their ease of programming, high productivity, and superior part quality. This saves the company time and money. Additionally, the high part quality minimises the need for manual rework, which in turn reduces employee workload.

Consistency and loyalty

However, modern machines alone are not enough to ensure long-term success. "The employees have to be in a good mood when they arrive at the factory," explains Isidro Lobo. The management contributes to this by exemplifying consistency. The family-run company from Guimarães is known for avoiding rash and ill-considered decisions. Lobo himself embodies this continuity like no other, having run the business for over 40 years. In the future, the company will remain in the hands of an experienced team.

The partnership with TRUMPF is also a long-term strategy. Jordão has recognised that the high-tech company can not only improve the quality of the products, but also the company's productivity. As in Germany, Portuguese companies are also suffering from a shortage of skilled labour.

The automation of processes using TRUMPF machines is therefore essential in order to remain competitive. As a next step, Jordão has plans to introduce the TRUMPF Oseon software for production control. This should help the company to further increase the level of automation and improve material flows.

Ambitious targets

Jordão has set ambitious targets for the future. "We want to double our 2022 turnover by 2026," says the Managing Director. The management has already paved the way for this future. Jordão has acquired two buildings adjacent to its existing factory, creating 10,000 square meters of new production space – representing the largest investment in the company's history. This was an important step in realising Jordão's growth strategy.

Interest in bespoke chiller cabinets is growing. "Food retail in particular has become more important in recent times," explains Lobo. Customers in the catering sector – such as hotels, restaurants, and cafés – remain highly important to Jordão. However, the company now also needs to cater to the needs of smaller supermarkets.

TRUMPF supports Jordão's growth strategy. As a leading provider and user of digitally networked production, the high-tech company possesses all the tools necessary to assist the Portuguese firm in making significant advancements in productivity through automation. TRUMPF sales representative Carlos Silva puts it succinctly: "Jordão realised that we can solve problems."