“Sheet metal is an absolute nightmare for cameras!” says Korbinian Weiß. He has spent years trying to make the two things more compatible. “Sheet metal is thin and bendy, it reflects light, it can be wobbly – and it comes in endless shapes and sizes,” he says. Cameras struggle to even recognize a metal surface – but artificial intelligence (AI) is offering new solutions to these problems.

Data provides the key

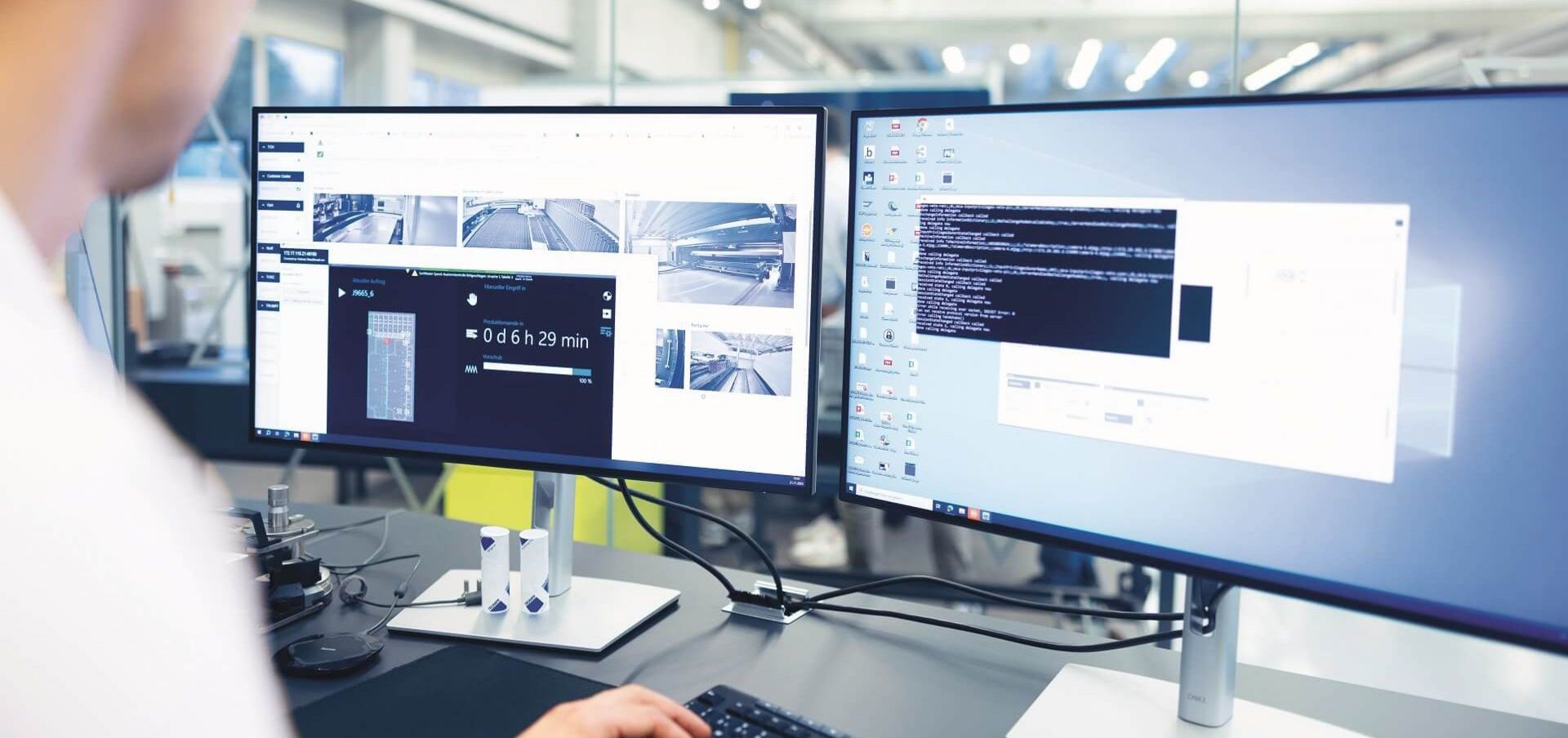

Weiß heads up the AI image-recognition team at TRUMPF in Ditzingen. His preference would be to have at least 24 cameras installed in machines such as the TruLaser Center 7030, TRUMPF’s first fully automated laser system. But right now the system has to make do with 12 cameras, which deliver huge quantities of images and video clips. These and many other types of data provide the key to continuously improving existing machines and developing entirely new products. This data forms the foundations of the computer vision team’s work. But what role does AI actually play in the TruLaser Center 7030 as it slices its way through one sheet after the next? And how do we define AI in this context anyway? AI is a research field with numerous sub-specialties, one of which is machine learning. In order for machines such as the TruLaser Center 7030 to “learn” – in other words, to get better and more efficient at what they do – they need tools and methods in the form of appropriate software. Computer vision is one of those methods.

Sorting Guide solution

Thirty-seven-year-old Weiß trained as a mechanical engineer, but he began developing software-driven initiatives not long after joining TRUMPF. One of the projects he led was the TRUMPF Sorting Guide, which did not originally include AI in its plans. The project team initially thought the Sorting Guide would work on the basis of conventional algorithms. “Everything seemed great in our test facility, the results were fantastic,” says Weiß. But then they took it to the test customer, “and nothing worked”. The problem was the lighting. The algorithms were overwhelmed by the mix of light and dark materials, the reflective surfaces, and all the objects in the visual environment. “Without AI, we wouldn’t have been able to cope,” he says. To train the AI, the computer vision team had to manually classify and label 100,000 images. By telling the system whether a sheet-metal part was visible or not in each image, and using the corresponding algorithms, the team was able to teach the software to continuously improve the accuracy of its predictions in multiple training loops.

AI isn’t everything

“Ninety-five percent of the solution is data, and just five percent AI,” says Weiß, explaining where the team had to focus their attention. “The challenge was collecting the data in the first place, curating and labeling it, compiling datasets to meet different problem-solving goals and getting the right balance within the data.” Sometimes traditional algorithms are all that are needed to solve a customer’s problem – but often it takes more. A lot has happened in the field of computer vision since TRUMPF launched its Sorting Guide in 2020. As well as improvements in the technology and algorithm databases, there has also been a shift in people’s mindset. “Nowadays, we’re thinking about data from the moment we start developing a product,” says Weiß. That’s why the TruLaser Center 7030 contains cameras. And it’s also why TRUMPF now has access to entirely new business models – one of which is Pay per Part.

Remote night shifts

In this business model, TRUMPF’s fully automated flagship is located at the customer’s site, where it produces the desired parts; but control of the machine lies in the hands of a TRUMPF team at the Neukirch site in Saxony, which operates in three shifts, including at night. The cameras keep the team updated on every aspect of the machine’s operation and deliver a non-stop stream of data. If a sheet-metal part gets stuck, the cameras record a short clip starting a few seconds before the event and ending a few seconds after. This helps the AI learn how to avoid such errors in the future. AI offers numerous potential benefits and uses, some of which arestill in their infancy. Examples include more-efficient machine utilization, longer running times, higher part quantities, savings on materials, predictive maintenance and assistance systems. “There’s a lot happening in computer vision at the moment,” says Weiß. He is excited about 2024, which will introduce features such as smart cameras – some even with AI functions – to TRUMPF machines.

Wake up!

Five years ago, Professor Dr. Sepp Hochreiter gave a presentation at Hannover Messe in which he called on the German mechanical engineering industry not to “drop the ball”. “You have a real edge in building machinery, so don’t throw it away!” he implored. Machine builders work blind, he said: they don’t have constant contact with their customers like Facebook or Apple, and even if they have customer data, they don’t tend to analyze it. “Machine builders and users need to wake up!” he says. Hochreiter is regarded as one of the world’s pre-eminent experts on artificial intelligence. Originally from Bavaria, he heads up the Institute for Machine Learning and the Artificial Intelligence Laboratory at Johannes Kepler University Linz. Last year, he received the German AI Award from the Axel Springer Group’s news brand Die Welt, the most generous award of its kind in Germany.

His current projects include his own language model, which is said to be far superior to ChatGPT. Five years after Hochreiter’s summons to arms, he insists that his wake-up call is as urgent as ever. Mechanical engineering companies may be making good progress, especially in south-west Germany, but he says that nowadays it’s not just about building the best machine, but what elements you add to it. He keeps a close eye on developments in this area – and he’s enthusiastic about the path TRUMPF has chosen. “They’re doing a great job!