Our Exhibits

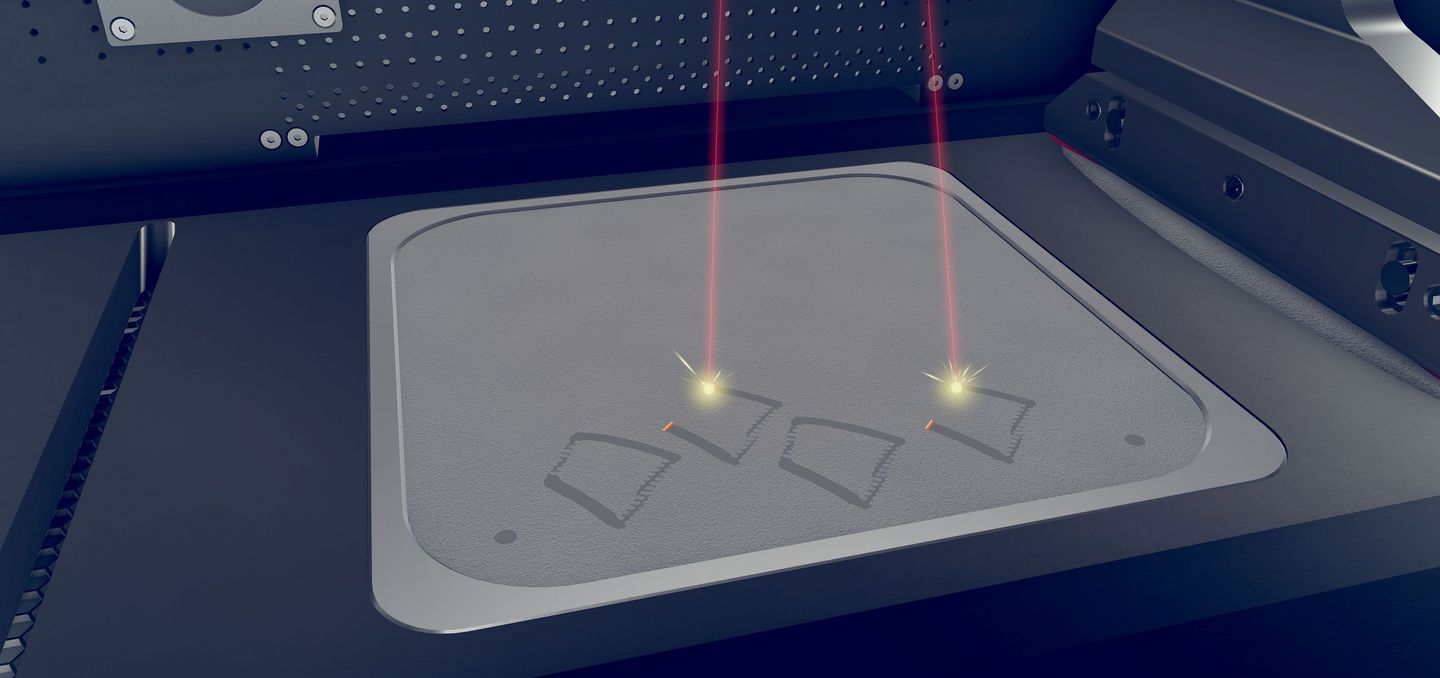

From powder to series production, you will find intelligent solutions at our stand. Our range includes the entire spectrum of machines, software & services, peripherals and monitoring.

The TruPrint 3000 is our versatile medium-format machine with industrial part and powder management. The new powder handling station, designed for easy sieving and conveying of metal powder within just 1 m², ensures consistently high powder quality. From now on, benefit from increased productivity thanks to the cooled build plate, the De-focus function, and full 700-watt laser power – perfect for processing specialty alloys and reducing your part costs.

In addition to our TruPrint machines, we offer you the complete package: customised software for data preparation, monitoring solutions for every phase of the printing process and a global service network. We support you from the production of a sample part in our application laboratory, through prototype production, to production on your own machine.

You can expect interesting applications from the General Industry, Aerospace, Energy, Mold & Die, Medical and Dental sectors, among others. We combine the right additive manufacturing system with tailored application support for your application and industry.

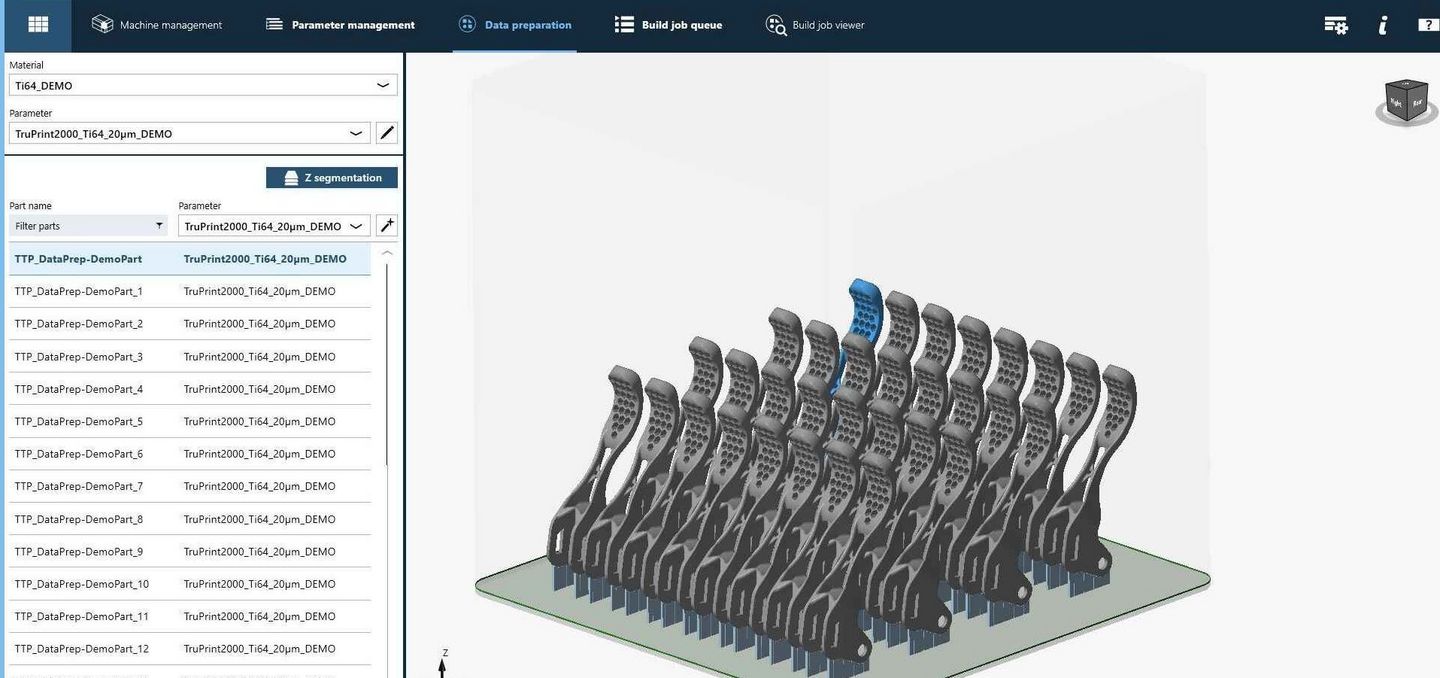

TruTops Print is the ideal software solution for seamless data preparation in 3D printing. It efficiently bridges the gap between design and printing, offering advanced features like slicing, vector generation, and laser assignment. With innovative strategies, it enables design freedom, reduces material consumption, and improves surface quality. Integrates with most CAD-CAM systems.

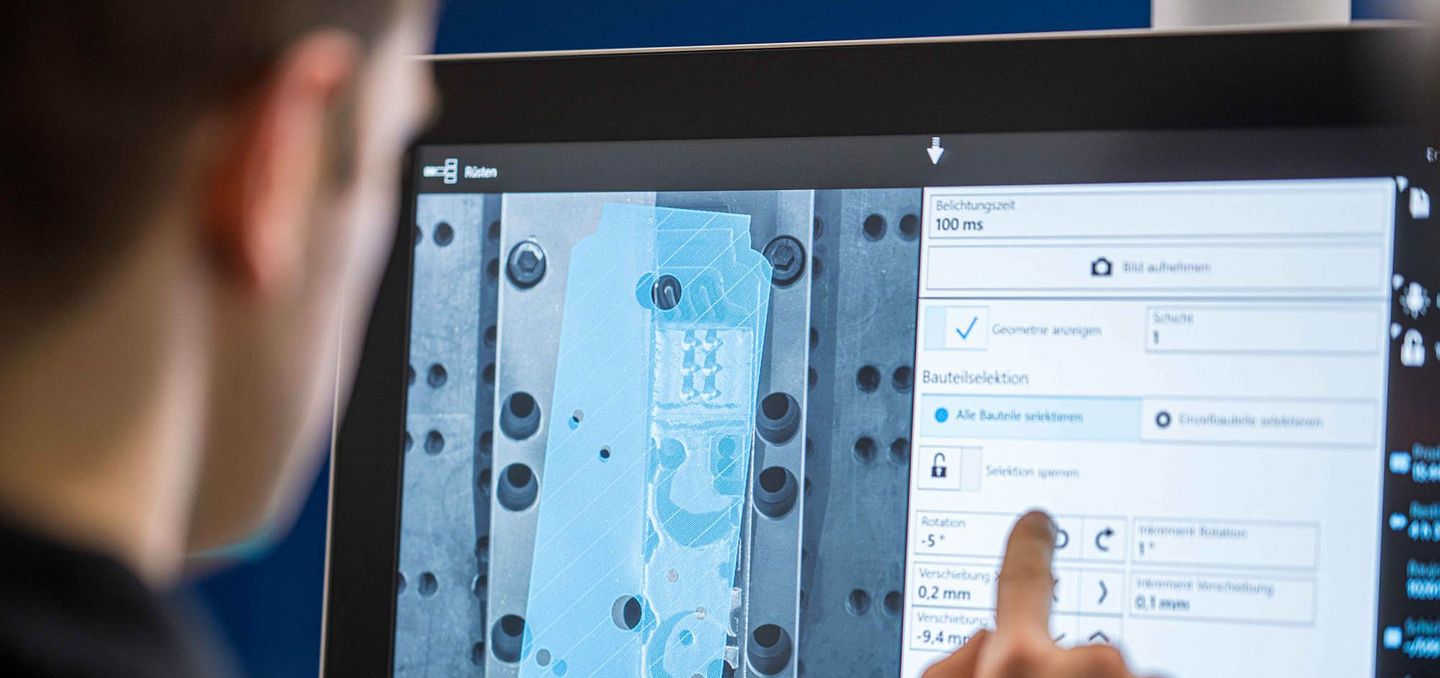

With our monitoring solutions, specifically Powder Bed and Melt Pool Monitoring, you gain full control over the part quality of your TruPrint machine. Powder Bed Monitoring tracks the powder bed during the exposure process, while Melt Pool Monitoring oversees the melt pool. This allows you to optimize production layer by layer and quickly identify errors for more efficient manufacturing.

With the Preform option, you achieve advantages through a clever combination of manufacturing techniques. Use the option for sustainable remanufacturing of individual components or for series production - and effectively reduce your construction costs.

The system offers fully automated online monitoring and correction of the laser beam sources with an accuracy of 27.5 µm. High-resolution camera systems and dark field illumination enable image recording, evaluation and correction during the construction job. Faults can be localized quickly and the measurement results are documented in the condition monitoring system.