When laser welding plastics using the transmission welding method, two types of thermoplastics are joined with one another: the laser passes through the transparent mating part and the absorbing mating part is heated. The absorbing plastic melts the transparent joining area. The mating parts must be pressed together using a suitable fixture in order to ensure sufficient heat transfer. As far as possible, the gap should be smaller than 150 μm here. In order to ensure a permanent connection, the melted plastic must solidify completely. The fixture therefore continues to press the two mating parts together for a given holding time after the actual welding process.

Laser plastic welding

High-quality, reproducible, and completely without solvents – laser-based joining of plastics has many advantages and replaces traditional processes in many industries such as adhesive bonding and ultrasound or vibration welding. When joining using a laser, the weld seam can also be adapted to new component geometries as desired. Since the heat input is severely limited locally, delicate electronic components are protected effectively, for example. A distinction is typically made between four versions of laser welding for plastics: contour welding, quasi-simultaneous welding, simultaneous welding, and mask welding. When it comes to plastic welding, laser powers of up to approx. 300 watts are generally used.

The weld seams are of a consistently high quality. The strength of the seams produced corresponds to that of the base material.

The weld seam can be adapted to various component geometries as desired.

Compared to adhesive bonding or vibration and ultrasound welding, no adhesive residues or plastic flakes are created when laser welding.

The heat input is restricted locally and is gentle on delicate electronics.

Laser plastic welding is not just gentle for the material, but also for the environment.

How does laser plastic welding work?

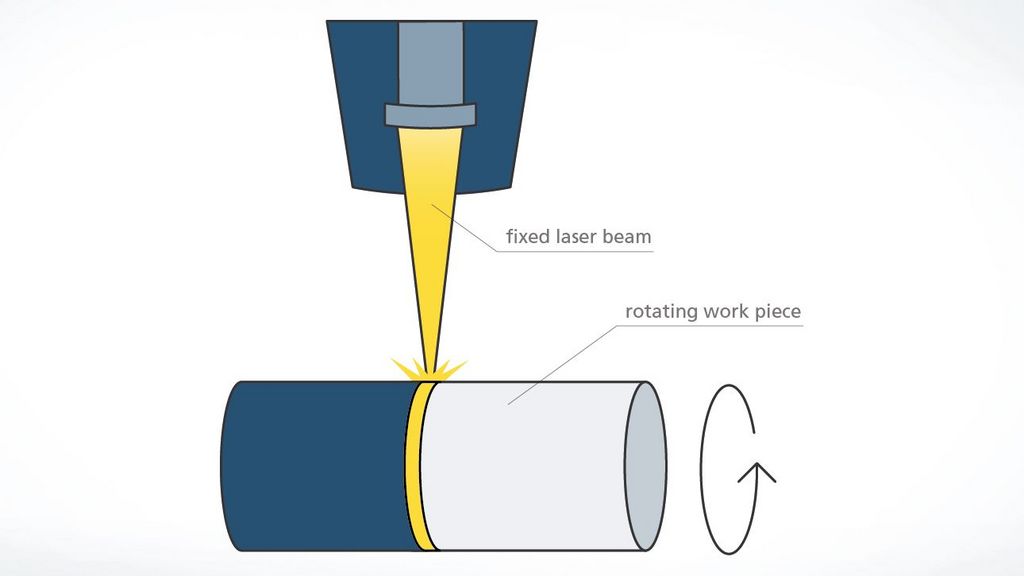

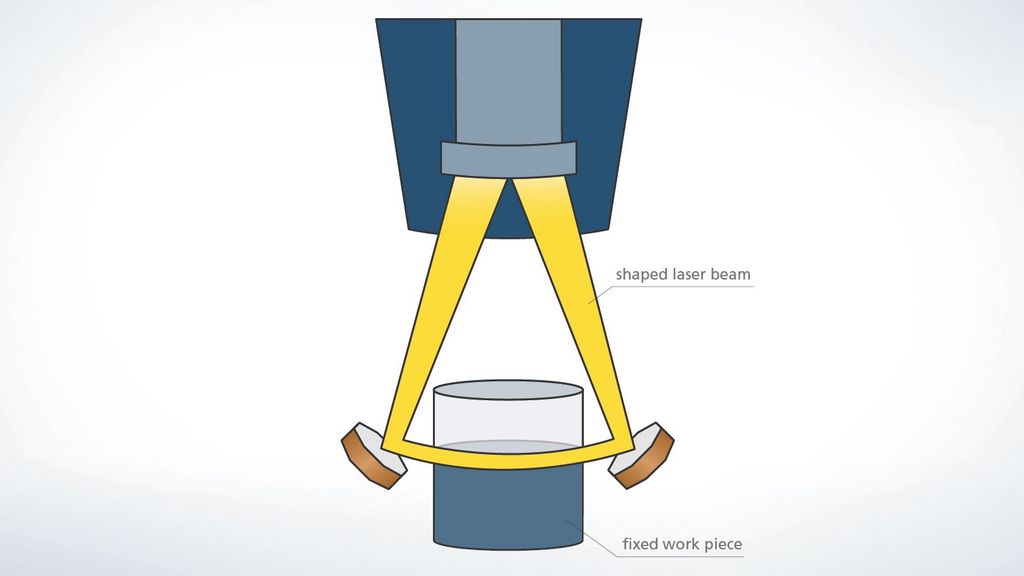

The three laser transmission welding processes compared

Typical areas of application for laser plastic welding

TRUMPF products for laser plastic welding

TRUMPF offers you the complete solution for plastic welding. You are provided with the laser, focusing optics with sensor system, and laser machine (with fixture upon request) all from a single source and perfectly adapted to your specific application.