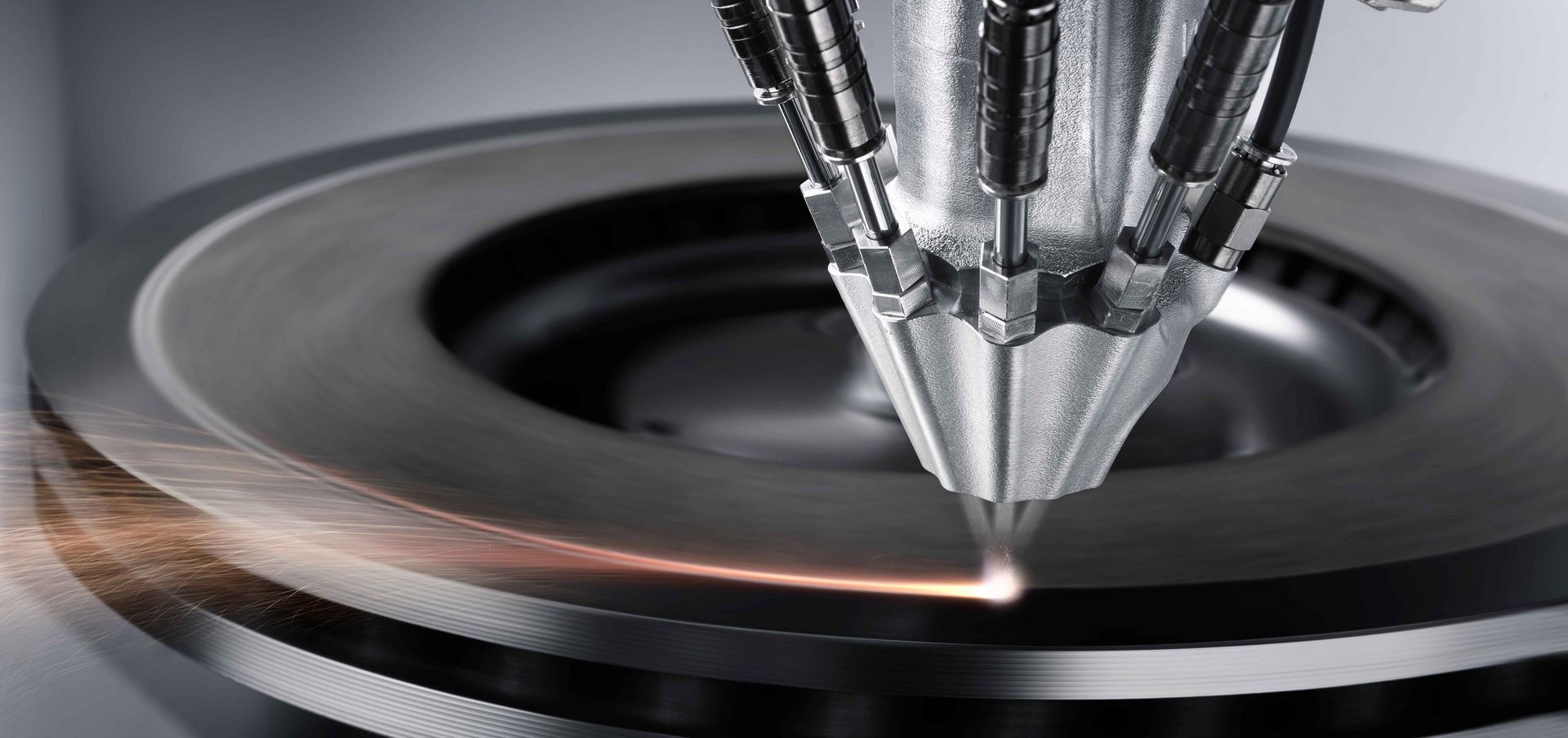

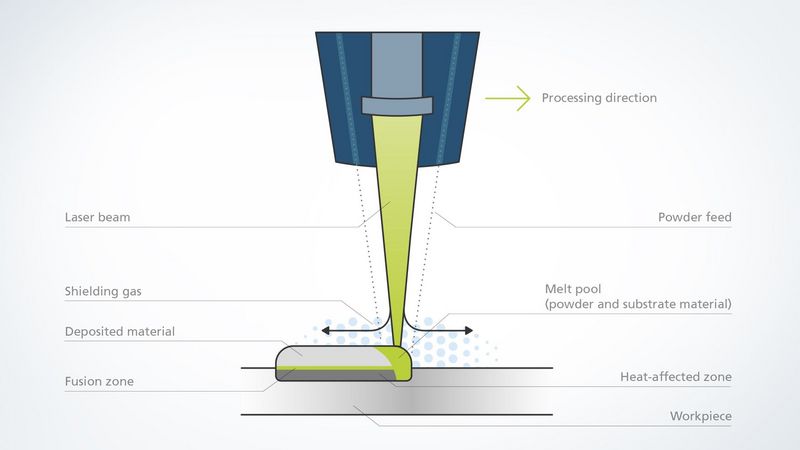

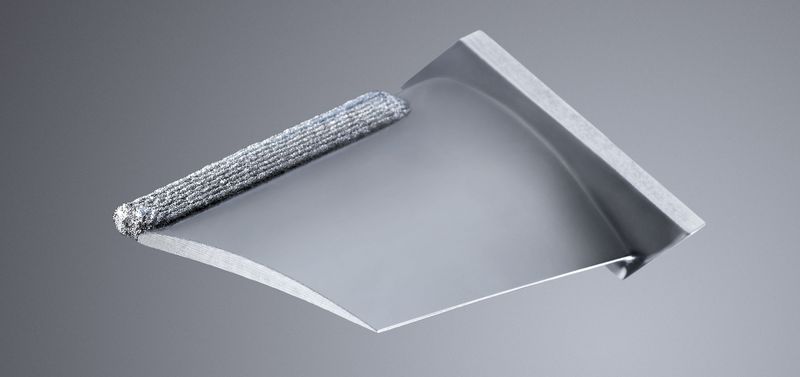

Laser metal deposition is an additive manufacturing method for metals and metal-ceramic compounds. It can be used to generate or modify 3D geometries. The laser can also perform repairing or coating processes with this manufacturing method. In the aerospace industry, additive manufacturing is used to repair turbine blades. In tool construction and mold making, broken or worn edges and shaping functional surfaces are repaired or even armored locally. Bearing points, rollers or hydraulic components in energy technology or petrochemistry are coated to protect against wear and corrosion. Additive manufacturing is also used in automotive engineering. In this industry, large numbers of components are refined.

TRUMPF customers benefit from the broad portfolio of lasers and laser systems. We have many years of process expertise and services for numerous laser technology applications. Additive manufacturing can also be combined with laser welding or laser cutting.