The right tricks allow you to design your parts more cost-effectively. The solution: Reducing the number of single parts and process steps. The support bracket shown here originally consisted of three parts connected with four weld seams, plus separately cut threads. It was redesigned out of just one bending part – without welding. An additional bend even allows you to reduce the sheet thickness and form the threads directly on the punching machine.

Sheet metal part design

Lighter, cheaper, or more functional: How would you like your parts? When sheet metal parts have a well-thought-out design, this allows your machines for laser cutting, punching, or bending to reach their full potential – while saving on materials, costs, and effort.

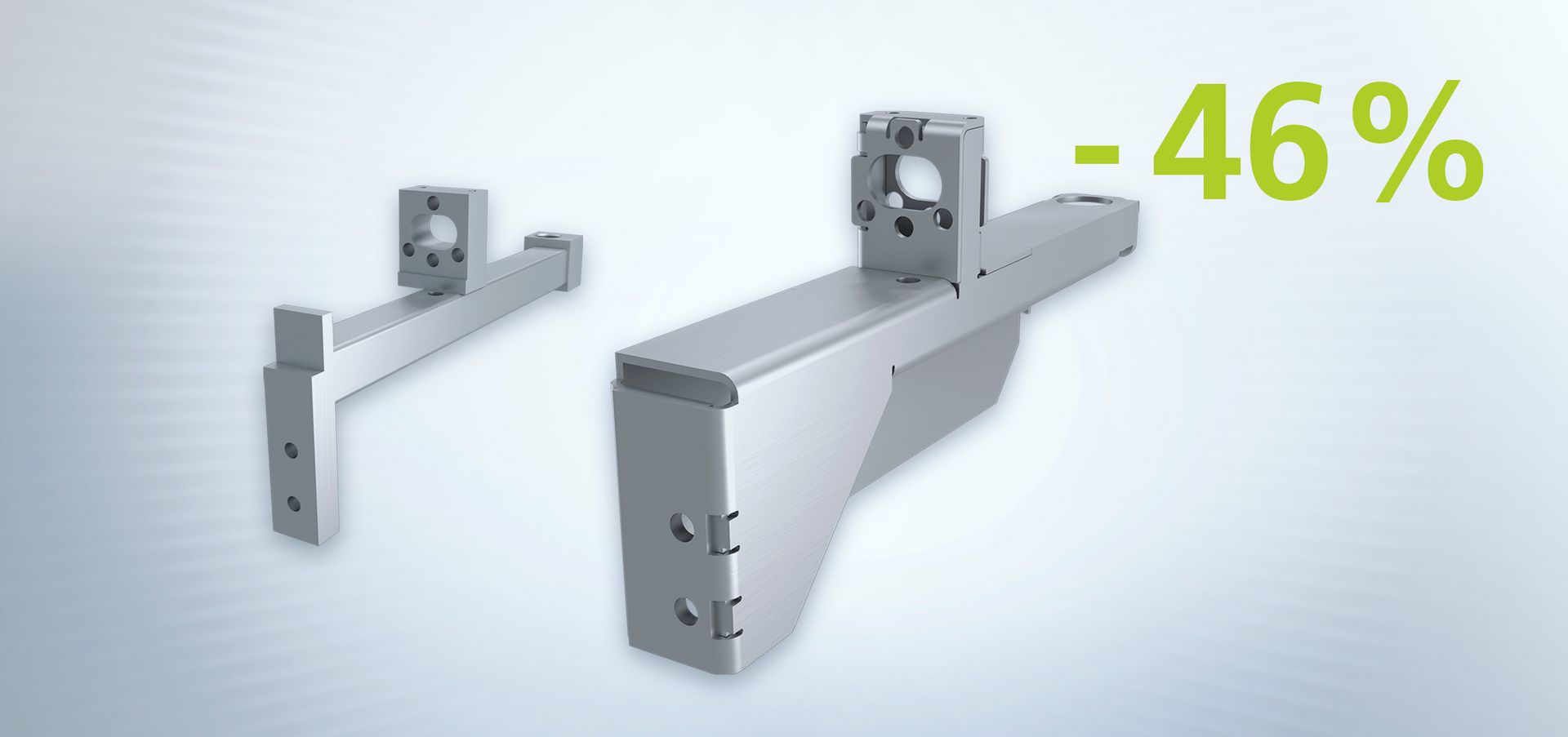

Example: Optimized axis stop

The axis stop is conventionally produced out of a welded construction with a semi-finished product and milled parts. The many work steps are both time-consuming and cost-intensive. The new design made of two sheet parts reduces the number of parts and thus the joining processes and material usage.

1. Sawing

...all components to size.

2. Milling

... the contact surfaces, oblong holes and stepping.

3. Drilling

... all holes in the components.

4. Welding

... all four components.

5. Laser cutting

... allows for any desired geometries to be cut into sheet metal, and creates bores.

6. Tapping

... for more strength compared to cut threads.

7. Bending

... replaces welding and decreases the number of parts.

8. -46% in costs

... with the new design