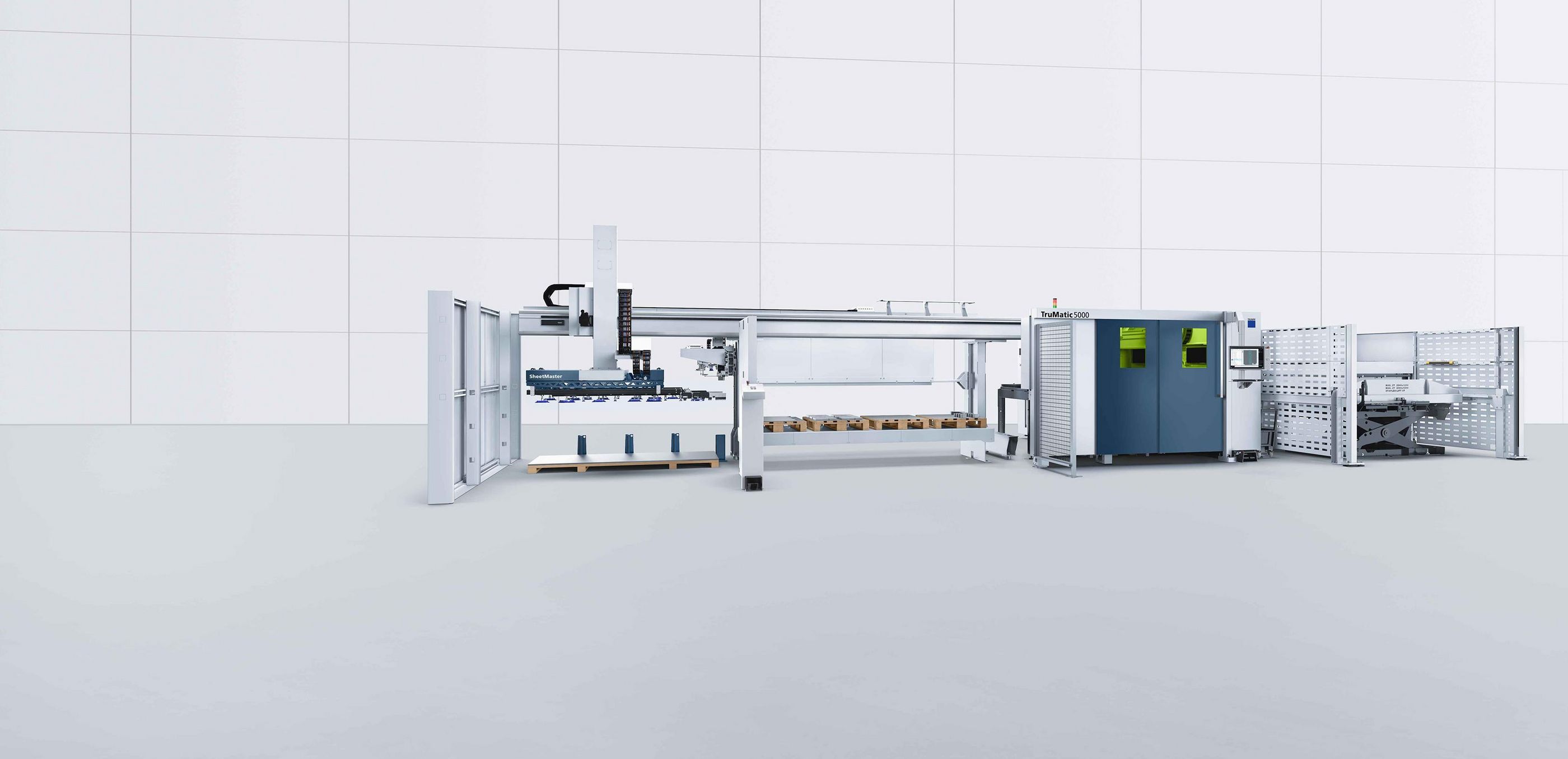

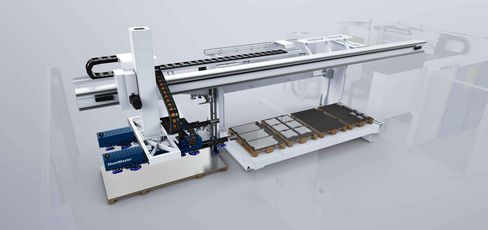

Outstanding part quality and fully automated material flow – from loading to production to sorting

The TruMatic 5000 with SheetMaster (new generation)* automates the material flow in your punch laser production, from fast loading to unloading, palletizing, and sorting. With 6 kW of laser power, the TruMatic 5000 is setting new productivity standards on the market and is simultaneously achieving high energy efficiency levels. Pre-separation of sheets parallel to production, the integrated axis for more flexibility, and a variety of individually controllable suction cups allow you to produce autonomously and efficiently.

The powerful 6 kW laser on the TruMatic 5000 makes your punch laser processing highly productive.

The automated punch laser system is ideal for multi-shift operation.

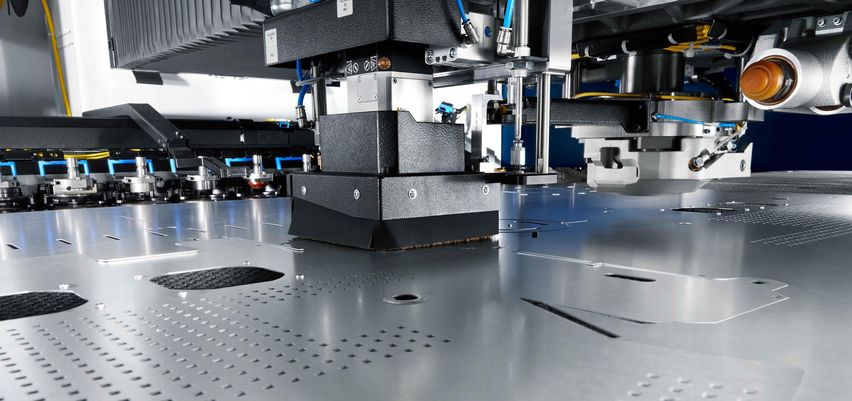

The descending die enables scratch-free punching and forming processes.

The ToolMaster changes tools fully automatically in the machine - for maximum safety in processes.

In addition to standard materials, the laser cuts a wide range of non-ferrous metals productively and reliably.

Solid-state lasers and delta drive of the machine score points for efficiency and energy conservation.

Extended forming options

High-quality outer contours and delicate inner contours: With the slim laser head of a TruMatic, you can cut very near to, or even on, formed sections that have already been introduced. These can be integrated quite easily into the process sequence.

Material range

The TruFiber solid-state laser is resistant to back-reflections. Even highly reflective materials such as copper or brass can be cut with a high level of process reliability.

|

TruMatic 5000 with new SheetMaster Medium Format

|

TruMatic 5000 with new SheetMaster Large Format

|

|

|---|---|---|

| Dimensions | ||

| Width | 17132 mm | 18880 mm |

| Depth | 10760 mm | 11260 mm |

| Height | 3700 mm | 3700 mm |

| Maximum stroke rate | ||

| Punching (E = 1 mm) | 800 1/min | 690 1/min |

| Marking | 1000 1/min | 1000 1/min |

| Working range | ||

| Punching mode, X axis | 2500 mm | 3000 mm |

| Punching mode, Y axis | 1250 mm | 1550 mm |

| Laser operation, X axis | 2500 mm | 3000 mm |

| Laser operation, Y axis | 1250 mm | 1550 mm |

| Combined operation, X axis | 2535 mm | 2535 mm |

| Combined operation, Y axis | 1250 mm | 1550 mm |

| Maximum sheet thickness | 6.4 mm | 6.4 mm |

| Maximum workpiece weight | 150 kg | 230 kg |

| Maximum punching force | 180 kN | 180 kN |

| Tools | ||

| MultiTool tool changing time | 0.5 s | 0.5 s |

| Number of tools/clamps | 21 pieces / 3 pieces | 21 pieces / 3 pieces |

| Laser-specific data - TruFiber 6001 | ||

| Maximum laser power | 6000 W | 6000 W |

| Maximum sheet thickness, mild steel | 8 mm | 8 mm |

| Maximum sheet thickness, stainless steel | 8 mm | 8 mm |

| Maximum sheet thickness, aluminum | 6 mm | 6 mm |

| Maximum sheet thickness, copper | 6 mm | 6 mm |

| Maximum sheet thickness, brass | 6 mm | 6 mm |

| Part removal | ||

| Maximum part size, fixed chute, punching (with moving table) | 180 mm x 180 mm | 180 mm x 180 mm |

| Maximum part size, part removal flap, laser | 400 mm x 600 mm | 400 mm x 600 mm |

| Loading the SheetMaster | ||

| Minimum sheet size | 800 mm x 800 mm | 800 mm x 800 mm |

| Maximum sheet size | 2500 mm x 1250 mm | 3067 mm x 1532 mm |

| Minimum sheet thickness | 0.5 mm | 0.5 mm |

| Maximum sheet thickness | 8 mm | 6.4 / 8.0 mm |

| Maximum sheet weight | 240 kg | 240 / 300 kg |

| Unloading the SheetMaster | ||

| Minimum part size (punching parts) | 140 mm x 120 mm | 140 mm x 120 mm |

| Minimum part size (laser cut parts) | 70 mm x 30 mm | 70 mm x 30 mm |

| Max. stack height (unloading platform) | 340 mm 1 | 340 mm 1 |

Be it a descending die or universal cutting unit: The equipment features are adapted to your punch laser system and support you in many ways in routine industrial operations.

Quality

The descending die enables scratch-free punching and forming processes. If requested, the die is lowered during positioning so that the sheet does not contact the die - be it a punching die or an raised forming die.

For sensitive materials, which must not have any scratches underneath, you can use brush tables combined with the descending die.

Process reliability

Smart Load and Unload supports process-reliable loading and unloading. During loading, a sensor in the clamps detects whether the sheet is optimally positioned. If this is not the case, the sheet is corrected. During unloading, a sensor detects whether a part was not safely removed. The new SheetMaster also performs an inspection before the parts are removed. This enables safe removal of the parts.

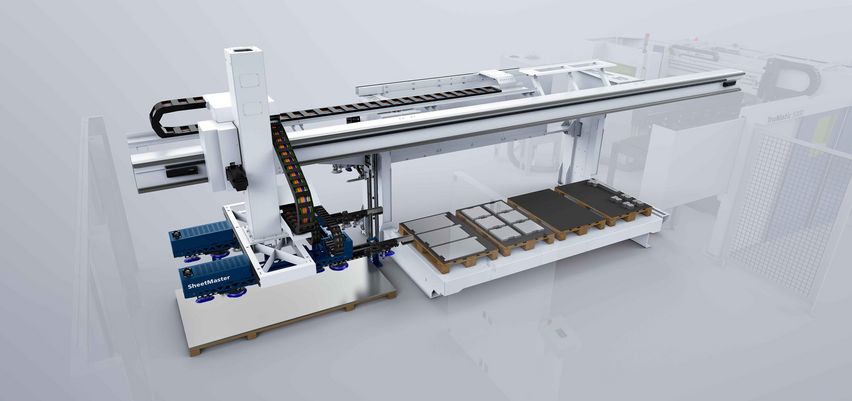

The separation station of the SheetMaster can pre-separate parallel to production. The gripping unit can pick up a separated raw sheet immediately after the last finished part has been sorted.

Before the tool change, smart punch monitoring checks whether a hole was actually punched into the sheet. This allows the machine to detect a possible broken punch at an early stage and avoids rejects, especially during night or weekend shifts.

Seamless integration of multiple TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Cost-effectiveness

When punching sheets, compressive and tensile stresses occur in the workpiece, which can lead to deformations in the sheet metal. The integrated flattening machine function and the corresponding tool make it possible to even out surface irregularities during the punching process itself.

Your TruMatic is equipped with a reliable universal cutting unit corresponding to the solid-state laser. This earns high marks due to its improved process reliability and simplified operation. Its robust design is built for everyday industrial use and makes it resistant to collisions.

Flexibility

With TRUMPF's Mobile Control app you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto your tablet's touch screen. In addition to the static control panel, you have another option for monitoring and controlling your machine.

Productivity

With 6 kW of laser power, the TruFiber laser enables unprecedented productivity. The solid-state laser guarantees a high level of efficiency and an excellent energy balance.

The new SheetMaster* loads the TruMatic 5000 with raw sheets and takes over the unloading and sorting of finished parts. Its new flexible gripping unit with its individually controllable suction cups make the SheetMaster highly effective in removing both simple and complex parts. This means manual interventions are hardly ever necessary.

TruTops Boost

Design and program your punch laser machine intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes take over time-consuming routine processes. In addition, the joint nesting pool saves time and material. With TruTops Boost you always have an overview of all production orders and work in an order-oriented manner.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

You can use the roller technology to create straight and curved beads of any length in the sheet. This produces high-quality workpieces without visible forming marks.

Deburr geometries of different sizes directly on the machine. As such, you benefit from perfectly deburred workpieces and shorter production times.

Remove small laser cut parts with process reliability and separate finished parts from remaining parts at the same time.

You can boost the productivity of your punching or punch laser machine with a tool adapter for up to ten inserts – in particular for small punching operations.

The descending die enables a scratch-free punching and forming operation and prevents the risk of things getting caught.

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

With the automation of your TruMatic 5000, you benefit from higher machine utilization and process reliability in automated multiple-shift operation. The modular concept also provides you with flexibility and opportunities for growth.

Automated loading and unloading with sorting

The SheetMaster (new generation)* takes over the fast and safe loading, unloading, separating, palletizing and sorting of your finished parts.

Disposal

The GripMaster (new generation)* ensures automated scrap skeleton handling. Scrap skeletons and remainder strips are deposited on the scissor table.

Tool handling

The ToolMaster Linear also provides space for an additional 18, 54 or 90 tools which are automatically positioned in the linear magazine of your machine. This means you can complete even complex orders with numerous tool changes quickly and automatically.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Without load carrier