Move by hand or by forklift truck and use immediately.

Automation happens just that fast

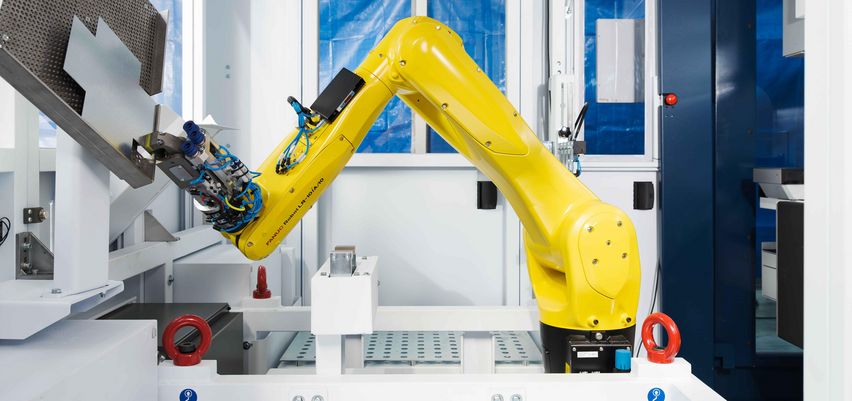

The Flex Cell bending automation transforms your manual TruBend 7050 into the fastest bending cell from TRUMPF. When urgent orders are due, you can use Flex Cell to scale your production capacity for simple parts in no time at all. And without the need for additional staff at the machine. This relieves your team and allows you to run autonomous shifts. Simply connect the mobile robot cell to your bending machine. This gives you a fully automated bending cell with generously sized raw material storage and a compact installation area.

The fastest bending cell for simple components from TRUMPF

Double loading capacity enables autonomous runtime up to 42 hours.

Automated bending power in the smallest of spaces (< 10 m²).

Produce challenging components manually, simple components automatically. The Flex Cell is ready for production in just a few minutes.

|

Flex Cell*

|

|

|---|---|

| Minimum part size | 70 mm x 50 mm |

| Maximum part size | 600 mm x 400 mm |

| Minimum sheet thickness | 0.7 mm |

| Maximum sheet thickness | 6 mm |

| Maximum part weight | 5 kg |

| Dimensions | |

| Height | 2200 mm |

| Length | 2400 mm |

| Width | 2000 mm |

The technical data of all product versions as a download.

Why is the mobile Flex Cell bending automation so fast? Learn more about its technical properties here.

High performance, accurate, and lightweight: With the 6-axis industrial robot you can achieve a high level of part precision and low cycle times. The mechanical high-speed clamping enables grippers to be replaced quickly.

You do not need to stack the blanks in the loading area precisely as the centering table will position them accurately. This increases the security of your processes and saves time. The perforated sheet on the surface prevents parts from being attached.

The combination of vacuum and pivoting-jaw grippers makes the Flex Cell particularly powerful. Its movable vacuum unit ensures minimal obstruction when bending. The gripper is also designed to overlap flanges.

Guarantees a high level of process reliability: sheet thickness measuring is used to detect at an early stage whether the gripper has picked up two metal sheets. The double sheet detection is also used as a regripping station.

Thanks to the conveyor belt, even delicate parts can be safely discharged. It can also be undocked quickly, offers plenty of space for the operator and has hardly any disruptive contours for the additional material flow.

Two regripping stations are integrated in the Flex Cell: a fixed one for smaller parts and an adjustable one for larger parts. The safe collection of the bending parts is ensured by the independently generated vacuum of each suction cup. Short paths enable fast regripping thus reducing the cycle times.

Filling and emptying made easy: With the loading and unloading carts, the next parts can be prepared during production and then changed quickly and easily.

Goniometer on the Flex Cell: Thanks to the new ACB "smart” method, the Flex Cell can be equipped with both ACB Wireless and ACB Laser.

With the vacuum gripper, larger components up to 600 x 400 mm can also be produced in the Flex Cell. The additional swivel axis reduces the need to reach around the component.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

*depending on the options selected