TruLaser 3030 fiber / 3040 fiber / 3060 fiber / 3080 fiber

Flexible standard machine

Close

Flexible standard machine

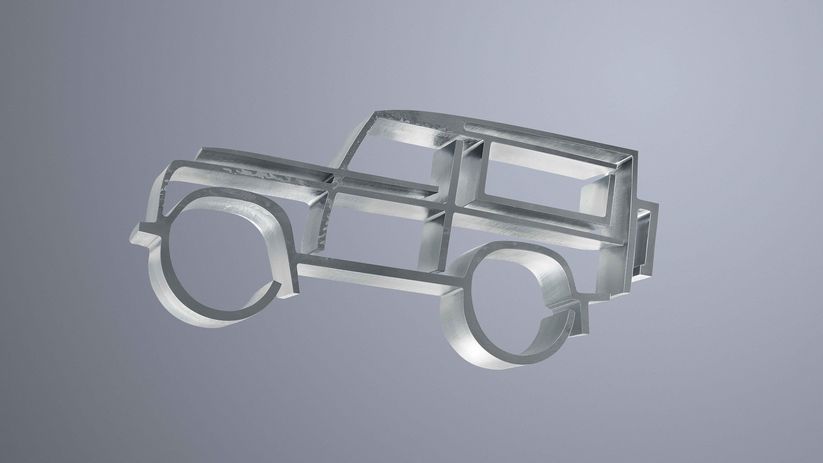

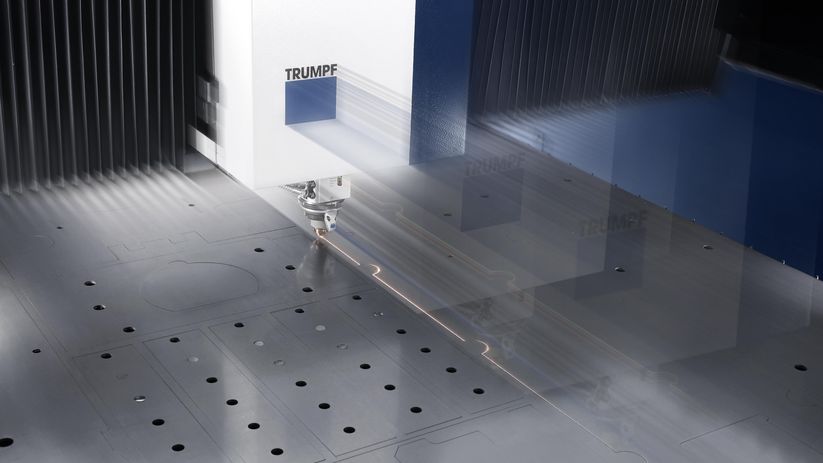

TruLaser 3030 fiber, TruLaser 3040 fiber, TruLaser 3060 fiber and TruLaser 3080 fiber – the fast machines for all your cutting tasks. They impress with their high level of flexibility and cost-effectiveness: You can cut all sheet thickness profitably. The TruDisk solid-state laser enables the processing of non-ferrous metals and provides you with a productivity benefit in thick and thin sheet. BrightLine fiber guarantees the highest edge quality and facilitates part removal. Numerous other functions ensure the highest reliability and performance possible.

BrightLine fiber facilitates excellent part quality and seamless part removal.

With the CoolLine function, you can even create small contours in thick mild steel.

Using Drop&Cut, you can easily post-produce parts from remainder sheets.

The menu navigation on the large display works intuitively. Integrated cutting parameters increase the level of process reliability.

Condition Guide always monitors the condition of your machine.

Smart collision prevention reduces the risk of collisions during laser cutting.

DetectLine determines the position of the sheet and enables precise post-processing of cut parts.

A new nozzle design reduces nitrogen consumption by up to 70% – for double the sheet throughput.

With an output of 24 kW, the TruDisk 24001 cuts up to three times faster

Thin mild steel part

Your TruLaser 3030 fiber / 3040 fiber / 3060 fiber / 3080 fiber cut extremely quickly, particularly in thin sheets.

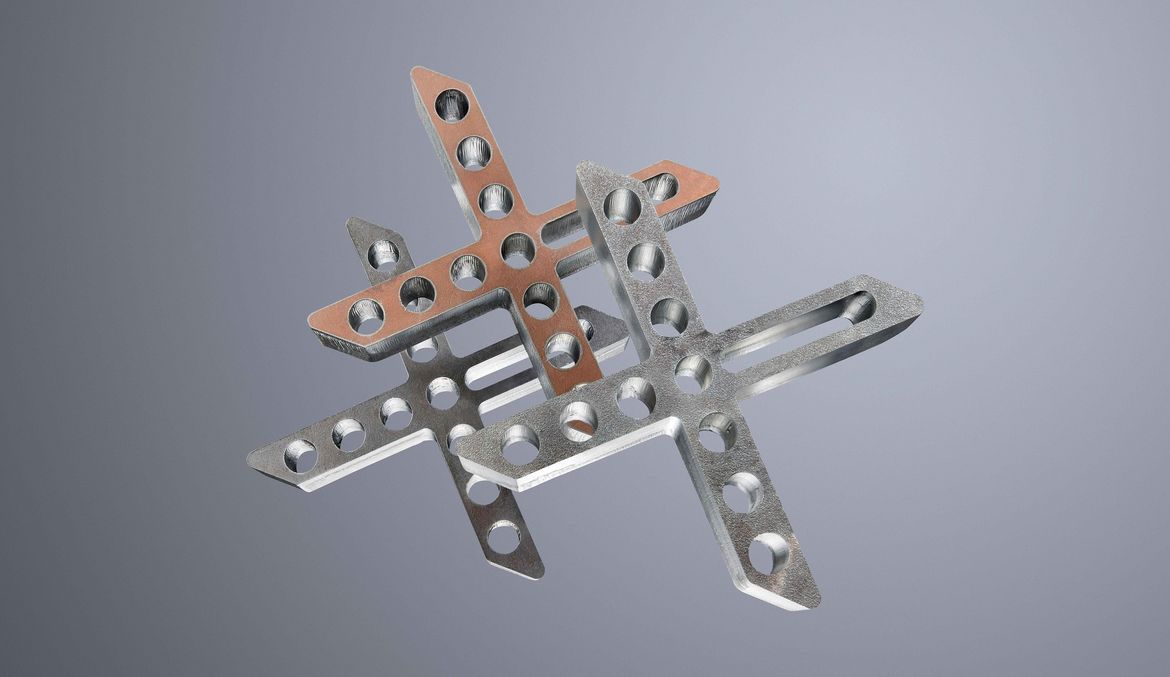

Parts which are easy to remove

With BrightLine fiber, a sophisticated combination of special optics, together with the flow-optimized BrightLine nozzles and other technical innovations, TruLaser 3030 fiber / 3040 fiber / 3060 fiber / 3080 fiber provide top part quality. The highlight: Due to the high-quality cutting edges, parts do not get caught during removal. It is easy to remove the parts and you save a lot of time.

Cutting of all common materials

The construction of the TruDisk enables the processing of non-ferrous metals with nitrogen – without worrying about reflections. You can also process film-coated sheets.

Thick mild steel cut with CoolLine

The CoolLine process specifically cools the workpiece during laser cutting. This enables new geometries and considerably increases process reliability in thick mild steel.

Thick mild steel

Strong and high-quality: The powerful TruDisk 24001 easily cuts mild steel up to 50 mm thick.

Use FlexLine when cutting fluctuating steel and surface qualities

With FlexLine you can cut structural steel of different grades robustly, safely and with a high level of quality. This is ensured by special cutting parameters and a patented nozzle design.

|

TruLaser 3030 fiber

Compare product

|

TruLaser 3040 fiber

Compare product

|

TruLaser 3060 fiber

Compare product

|

TruLaser 3080 fiber

Compare product

|

|

|---|---|---|---|---|

| Dimensions | ||||

| Length | 9229 mm | 11200 mm | 15450 mm | 19620 mm |

| Width | 6145 mm | 6373 mm | 6878 mm | 6968 mm |

| Height | 2200 mm | 2200 mm | 2200 mm | 2200 mm |

| Weight | ||||

| Weight of basic machine | 11700 kg 1 | 14300 kg 1 | 19800 kg 1 | 21850 kg 1 |

| Maximum speed | ||||

| Simultaneous | 170 m/min | 170 m/min | 170 m/min | 170 m/min |

| Working range | ||||

| X axis | 3000 mm | 4000 mm | 6000 mm | 8000 mm |

| Y axis | 1500 mm | 2000 mm | 2500 mm | 2500 mm |

| Maximum workpiece weight without heavy-duty pallet changer | 1100 kg | 2000 kg | 2900 kg | 4710 kg |

| Maximum workpiece weight with heavy-duty pallet changer | 1800 kg | 3300 kg | 4900 kg | 7850 kg |

| Maximum workpiece weight on both pallets with heavy-duty pallet changer | 2200 kg 2 | 3900 kg 2 | 5700 kg 2 | 9420 kg 2 |

| Laser-specific data - TruDisk 4001 | ||||

| Maximum laser power | 4000 W | 4000 W | 4000 W | 4000 W |

| Maximum sheet thickness, mild steel | 22 mm | 22 mm | 22 mm | 22 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, stainless steel | 20 mm | 20 mm | 20 mm | 20 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 20 mm | 20 mm | 20 mm | 20 mm |

| Maximum sheet thickness, copper | 8 mm | 8 mm | 8 mm | 8 mm |

| Maximum sheet thickness, brass | 8 mm | 8 mm | 8 mm | 8 mm |

| Laser-specific data - TruDisk 6001 | ||||

| Maximum laser power | 6000 W | 6000 W | 6000 W | 6000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, copper | 10 mm | 10 mm | 10 mm | 10 mm |

| Maximum sheet thickness, brass | 10 mm | 10 mm | 10 mm | 10 mm |

| Laser-specific data - TruDisk 8001 | ||||

| Maximum laser power | 8000 W | 8000 W | 8000 W | 8000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 10 mm | 10 mm | 10 mm | 10 mm |

| Laser-specific data - TruDisk 10001 | ||||

| Maximum laser power | 10000 W | 10000 W | 10000 W | 10000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum sheet thickness, aluminum | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Laser-specific data - TruDisk 12001 | ||||

| Maximum laser power | 12000 W | 12000 W | 12000 W | 12000 W |

| Maximum sheet thickness, mild steel | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 50 mm | 50 mm | 50 mm | 50 mm |

| Maximum sheet thickness, aluminum | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Laser-specific data - TruDisk 24001 | ||||

| Maximum laser power | 24000 W | 24000 W | 24000 W | 24000 W |

| Maximum sheet thickness, mild steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 60 mm | 60 mm | 60 mm | 60 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 60 mm | 60 mm | 60 mm | 60 mm |

| Maximum sheet thickness, aluminum | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum sheet thickness, copper | 16 mm | 16 mm | 16 mm | 16 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Consumption values | ||||

| Average power input in production - TruDisk 4001 | 13 kW | 13 kW | 13 kW | 13 kW |

| Average power input in production - TruDisk 6001 | 15 kW | 15 kW | 15 kW | 15 kW |

| Average power input in production - TruDisk 8001 | 17 kW | 17 kW | 17 kW | 17 kW |

| Average power input in production - TruDisk 10001 | 19 kW | 19 kW | 19 kW | 19 kW |

| Average power input in production - TruDisk 12001 | 25 kW | 25 kW | 25 kW | 25 kW |

| Average power input in production - TruDisk 24001 | 33 kW | 33 kW | 33 kW | 33 kW |

|

Compare products

End comparison

|

TruLaser 3030 fiber

|

TruLaser 3040 fiber

|

TruLaser 3060 fiber

|

TruLaser 3080 fiber

|

|---|---|---|---|---|

| Dimensions | ||||

| Length | 9229 mm | 11200 mm | 15450 mm | 19620 mm |

| Width | 6145 mm | 6373 mm | 6878 mm | 6968 mm |

| Height | 2200 mm | 2200 mm | 2200 mm | 2200 mm |

| Weight | ||||

| Weight of basic machine | 11700 kg 1 | 14300 kg 1 | 19800 kg 1 | 21850 kg 1 |

| Maximum speed | ||||

| Simultaneous | 170 m/min | 170 m/min | 170 m/min | 170 m/min |

| Working range | ||||

| X axis | 3000 mm | 4000 mm | 6000 mm | 8000 mm |

| Y axis | 1500 mm | 2000 mm | 2500 mm | 2500 mm |

| Maximum workpiece weight without heavy-duty pallet changer | 1100 kg | 2000 kg | 2900 kg | 4710 kg |

| Maximum workpiece weight with heavy-duty pallet changer | 1800 kg | 3300 kg | 4900 kg | 7850 kg |

| Maximum workpiece weight on both pallets with heavy-duty pallet changer | 2200 kg 2 | 3900 kg 2 | 5700 kg 2 | 9420 kg 2 |

| Laser-specific data - TruDisk 4001 | ||||

| Maximum laser power | 4000 W | 4000 W | 4000 W | 4000 W |

| Maximum sheet thickness, mild steel | 22 mm | 22 mm | 22 mm | 22 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, stainless steel | 20 mm | 20 mm | 20 mm | 20 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 20 mm | 20 mm | 20 mm | 20 mm |

| Maximum sheet thickness, copper | 8 mm | 8 mm | 8 mm | 8 mm |

| Maximum sheet thickness, brass | 8 mm | 8 mm | 8 mm | 8 mm |

| Laser-specific data - TruDisk 6001 | ||||

| Maximum laser power | 6000 W | 6000 W | 6000 W | 6000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, copper | 10 mm | 10 mm | 10 mm | 10 mm |

| Maximum sheet thickness, brass | 10 mm | 10 mm | 10 mm | 10 mm |

| Laser-specific data - TruDisk 8001 | ||||

| Maximum laser power | 8000 W | 8000 W | 8000 W | 8000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, aluminum | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 10 mm | 10 mm | 10 mm | 10 mm |

| Laser-specific data - TruDisk 10001 | ||||

| Maximum laser power | 10000 W | 10000 W | 10000 W | 10000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm | 25 mm | 25 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 32 mm | 32 mm | 32 mm | 32 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum sheet thickness, aluminum | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Laser-specific data - TruDisk 12001 | ||||

| Maximum laser power | 12000 W | 12000 W | 12000 W | 12000 W |

| Maximum sheet thickness, mild steel | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 35 mm | 35 mm | 35 mm | 35 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 50 mm | 50 mm | 50 mm | 50 mm |

| Maximum sheet thickness, aluminum | 30 mm | 30 mm | 30 mm | 30 mm |

| Maximum sheet thickness, copper | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Laser-specific data - TruDisk 24001 | ||||

| Maximum laser power | 24000 W | 24000 W | 24000 W | 24000 W |

| Maximum sheet thickness, mild steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum mild steel sheet thickness with cutting package for thick sheets | 60 mm | 60 mm | 60 mm | 60 mm |

| Maximum sheet thickness, stainless steel | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum stainless steel sheet thickness with cutting package for thick sheets | 60 mm | 60 mm | 60 mm | 60 mm |

| Maximum sheet thickness, aluminum | 40 mm | 40 mm | 40 mm | 40 mm |

| Maximum sheet thickness, copper | 16 mm | 16 mm | 16 mm | 16 mm |

| Maximum sheet thickness, brass | 12.7 mm | 12.7 mm | 12.7 mm | 12.7 mm |

| Consumption values | ||||

| Average power input in production - TruDisk 4001 | 13 kW | 13 kW | 13 kW | 13 kW |

| Average power input in production - TruDisk 6001 | 15 kW | 15 kW | 15 kW | 15 kW |

| Average power input in production - TruDisk 8001 | 17 kW | 17 kW | 17 kW | 17 kW |

| Average power input in production - TruDisk 10001 | 19 kW | 19 kW | 19 kW | 19 kW |

| Average power input in production - TruDisk 12001 | 25 kW | 25 kW | 25 kW | 25 kW |

| Average power input in production - TruDisk 24001 | 33 kW | 33 kW | 33 kW | 33 kW |

Process reliability and operator support

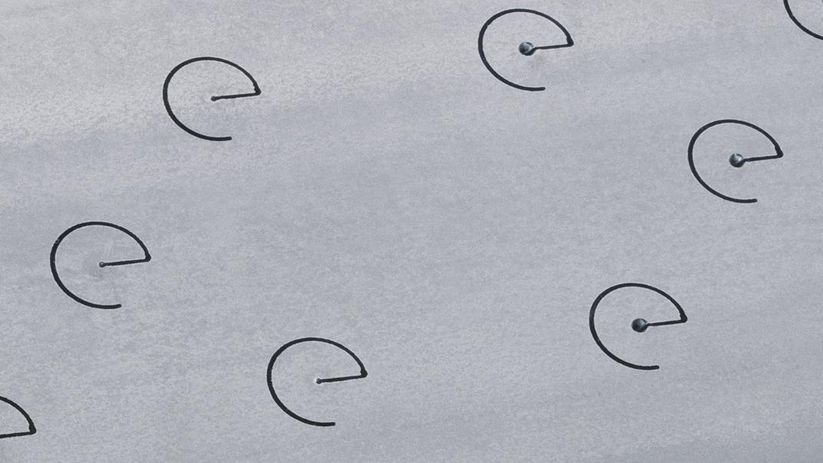

Regardless of the component geometry, nanojoints make process-reliable and resource-efficient machining of your components possible: higher productivity, better part quality, and simpler part removal thanks to minimal fixing in the scrap skeleton. In many cases, no reworking is necessary. In comparison, microjoints fix the component in the scrap skeleton with a tab across the entire sheet thickness. In most cases, the visible damage to contours requires time-consuming reworking of the components. Part removal is more complex with thin sheet thicknesses, with mid-range sheet thicknesses it is almost impossible.

Mild steel becomes extremely hot during laser cutting and may melt uncontrollably. With CoolLine, this does not happen. During processing, the cutting head sprays water mist in a circle around the laser beam onto the workpiece. This is possible due to nozzles with precise bore holes. The vaporization energy of the water means that the material around the laser beam is cooled. CoolLine therefore enables new geometries, closer nesting, and increases process reliability for the processing of thick mild steel considerably.

Collision protection for your cutting head guarantees the highest process reliability. You benefit from shorter non-productive times due to increased machine availability. In the event of collisions, damage to the cutting head is avoided.

Clean protective glass ensures high cut quality for the long term. A sensor permanently monitors the condition of the protective glass so that you know when it must be changed. Cleaning and replacement are only performed when required, saving costs.

Autonomous production and prevention of idle states: With Smart Rerun, your machine will independently continue production following a slight collision or cutting flaw. To prevent any rejects, the main focus is always for re-entry to be within the contour. Only if this is not possible, will the machine jump to the next part. The objective is always for production to continue.

AdjustLine enables the easy adjustment of the cutting process to materials of different quality. The function increases process reliability, above all when cutting material of a poor quality. For you this means less scrap and lower material costs. The operator can switch AdjustLine on or off at any time – programming is not required.

The Sorting Guide is a camera-based assistance system that assists the worker in removing and sorting sheet metal parts. It marks parts with different colors according to the customer order or subsequent process. This enables the worker to quickly, easily and correctly arrange the cut parts on pallets.

With Drop&Cut, remainder sheet is utilized more easily, intuitively, and efficiently. A camera ensures the live image of the machine interior appears directly on your user interface. You can position any number of part geometries on the remainder sheet. This saves time during the post-production of individual parts. Time-consuming process steps such as aligning the sheet, sheet position measurement or zero point displacement are not needed.

With the MobileControl app, you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. The app enables you to call up different machine information at different places in the working environment of the machine, such as the clearing area, or to change the program.

The Dot Matrix Code function facilitates fast, process reliable part identification with a standardized industrial code. Within seconds, the laser in your flatbed laser machine applies a 2D code (data matrix) made out of dots onto a part. It contains information for the process chain. The code calls up the corresponding program at the next machine, for example.

The user interface, which has won numerous awards, makes the machine particularly easy to use. Tasks are completed considerably faster. New functions can be learned intuitively via the large touch display.

Seamless integration of multiple TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Flexibility

The EdgeLine Bevel function can now do even more: Cut chamfers and indentations, and round off edges directly on your laser cutting machine. You can thus reduce the amount of work required for additional process steps and prevent sharp-edged sheet metal. Simple and quick programming from EdgeLine Bevel supports your range of applications. This specifically means that you can process chamfers with different angles and indentations in several sizes. In addition, rounded edges improve the visual appearance of your components and reduce the risk of cuts.

With the additional RotoLas device, you can also process tubes and profiles on your 2D laser cutting machine. You can convert your machine from flatbed to tube processing within a very short time. A flexible loading system different tubes and profiles with absolute accuracy, facilitating processing of XXL-format tubes and profiles with outer circles of up to 370 mm.

Autonomy

You will now receive two different modes of the function to prevent collisions. Whether sheet mode or single part mode, you can largely avoid using microjoints. saving costly rework. The parts can also be unloaded using an automated mechanism as they do not tip over.

A camera system precisely determines the position of inserted sheets and enables the rework of parts which have already been cut with absolute precision. DetectLine also automatically measures a cut focusing comb and sets the focal position.

Quality

BrightLine fiber turns the solid-state laser into a universal tool: The function provides you with high-quality cutting results over the entire range of sheet thicknesses. Furthermore, all of the advantages of the solid-state laser are retained, in particular the high speeds, during thin sheet processing.

PierceLine monitors and controls the piercing process. This saves material and preserves the machine, increasing part quality and shortening the piercing time by up to 80%

The integrated gas mixer combines the cutting gases nitrogen and oxygen - automatically and without any operator involvement. The use of a gas mixture of nitrogen and oxygen combined with high laser power improves the part quality in mild steel and aluminum. The burr of the laser-cut component can be reduced in relation to the material type, material alloy and material quality.

High material tolerance, stable process: With FlexLine you can achieve the best possible cutting results with structural steel of different grades. Thanks to the patented nozzle design and special cutting parameters, you can safely cut delicate contours - even in thick sheet metal. This way, you can remain flexible and make optimal use of your materials.

Productivity

Quick and economic – without compromising on quality: With Highspeed, you can set new records with the solid-state laser when it comes to cutting with nitrogen. As a result, you can almost double your sheet throughput for medium and thick mild steel and stainless steel sheets – the same goes for the feed rate. A special nozzle design also reduces your cutting gas consumption by up to 40%, and even prevents burr formation on contours with sharp edges.

Extremely quick, extremely economical: With this Highspeed process, you can reduce your cutting gas consumption for cutting with nitrogen by up to 60%. This is enabled by a patented nozzle design. At the same time, you can almost double your sheet throughput for medium and thick mild steel and stainless steel sheets, and increase the feed rate by up to 100%. Quality does not suffer as a result. Highspeed Eco even prevents burr formation on contours with sharp edges. The process also harnesses new sheet thicknesses for processing with nitrogen.

Ensuring the kilowatts hit the sheet metal: even high levels of laser power can be fully utilized with TRUMPF machines. The TruDisk laser with up to 12kW not only promises high feed rates, but more importantly processes the workpiece to the highest level of productivity. This accurate combination of laser power, machine design and intelligent functions produces the best parts in the shortest processing time. This applies to fusion cutting as well as to flame cutting, and also to more complicated applications, for example, fine contours or thick sheet metal.

The new TruDisk 24001 doubles the laser power of the TruLaser Series 3000 to a full 24 kW. The laser cutting machines thus process components three times as fast and increase the table throughput by up to 80% per hour depending on the material. Do you wish to further improve the productivity and part quality of your production process? Then you will certainly benefit from the 24 kW laser power of this laser. Especially components with medium or high sheet thicknesses will be able to be produced efficiently using all materials. By using the double laser power, you will also improve the quality of your cut parts.

Sustainability

With the energy-efficient process cooler, you can cool the machine and laser in one system with up to 50 % lower energy costs compared to the standard process cooler. The compact design ensures optimum cooling with reduced space requirements. Thanks to the intelligent combination of powerful cooling and minimal energy consumption, you achieve lower operating costs.

TruTops Boost

Construct and program your laser, punching, and combined punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

Choose the right automation components for your laser cutting machine from a large modular system. From semi-automatic loading to a fully automatic processing cell with storage connection, TRUMPF provides solutions which optimize your process chain.

Loading

Your entry into automation: The LoadMaster enables the automatic loading of your machine with raw sheets.

Loading and unloading

The compact LiftMaster Compact loads and unloads your machine completely automatically and extremely fast. With the LiftMaster Linear Basic you have the option of multiple-machine connection.

Loading and unloading / Part sorting

The automation solution, LiftMaster, covers a broad range of functions. It loads and unloads, but is also suitable for pallet handling or part removal. The LiftMaster Sort also separates finished parts from the scrap skeleton, while LiftMaster Store and LiftMaster Store Linear connect your system directly to the store. The SortMaster automatically sorts finished parts.

Storage system

With the storage systems of the TruStore Series 1000 and TruStore Series 3000 you can organize your material handling according to your requirements.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Entspricht dem Maschinengewicht mit Standardausstattung. Das Gewicht kann je nach Ausstattung variieren.

- The maximum workpiece weight on both pallets is identical. However, there are different distributions of the workpiece weight on the pallets. Without heavy duty pallet changer distribution max. 30 mm / 30 mm sheet thickness per pallet and format. With heavy duty pallet changer distribution max. 50 mm / 10 mm sheet thickness per pallet and format.