Forty-year-old company founder Jordan Yost loves seeking out new business opportunities. “I’ve always been fascinated by metalworking,” he says. “When I sold my car rental business, I realized the time had come to turn that passion into my career.” He spent two years sounding out the industry, understanding how it worked, exploring what could be improved, and analyzing its potential. But what ultimately closed the deal was the time he spent at a job shop run by a friend in Las Vegas, who produces parts for exhibition booths. That gave Yost a glimpse behind the scenes and all the practical experience he needed to reach a final decision. In 2018, together with his father Barry, Yost founded Precision Tube Laser (PTL), a provider of metal processing solutions.

From zero to hundred

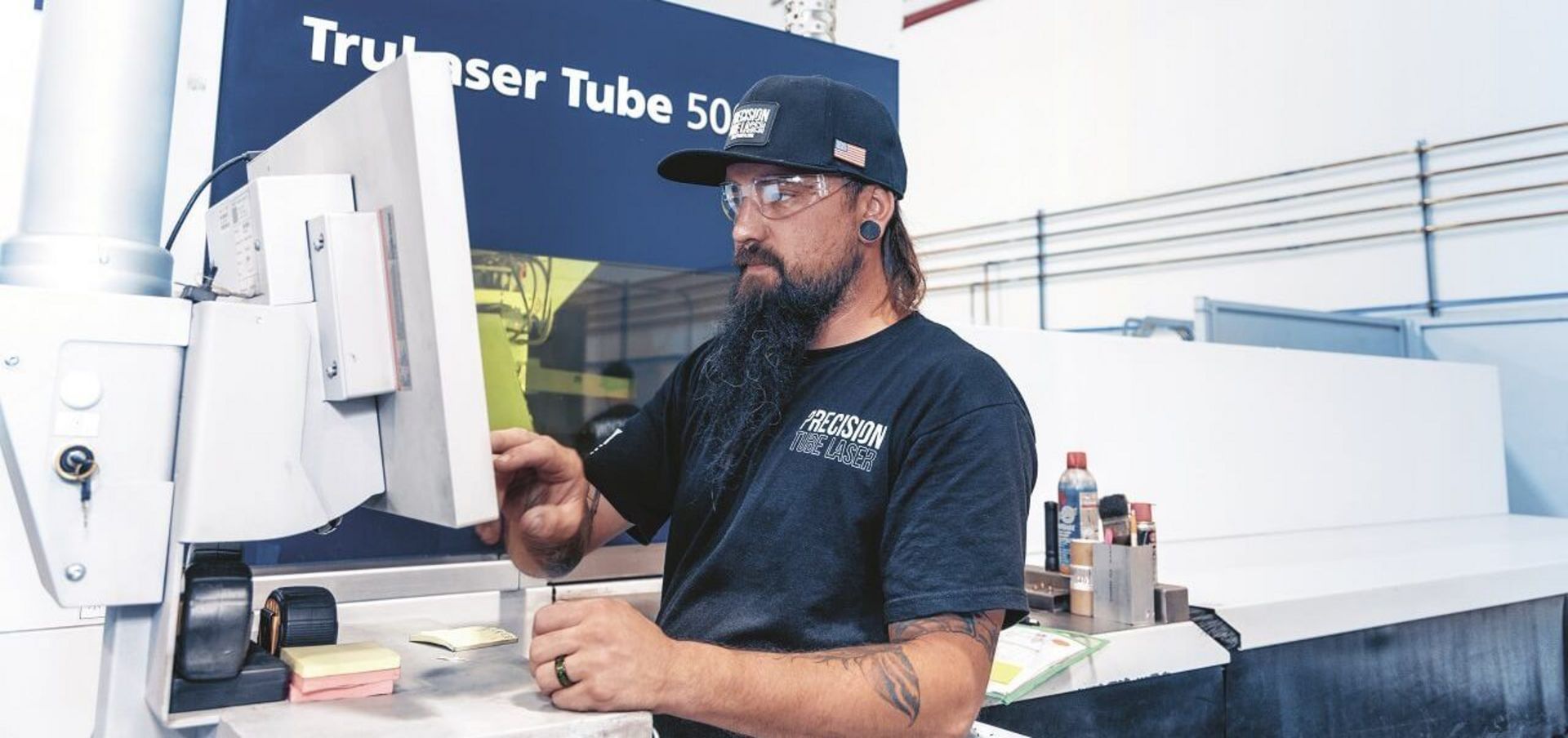

PTL embraced an innovative strategy right from the start, offering lead times of 3 to 5 days, no minimum quantities and affordable prices. Since then, Yost has done a remarkable job of positioning his company as one of the country’s leading fabricators of sheet-metal parts. “SMEs in the manufacturing industry have a tough time finding job shops that really cater to their needs. Our business model is to support SMEs by providing the high-quality sheet-metal parts they need in their day-to-day work, so they can focus on their core business,” says Yost. Determined to bring this vision of on-demand solutions to life, PTL realized it needed to maximize automation and seek out the most cutting-edge equipment on the market. Today, its production facilities on South Pearl Street in Las Vegas are kitted out almost exclusively with machine tools from TRUMPF, including a TruLaser Tube 5000 fiber, a TruLaser 1040 fiber, a TruBend 5170 with ToolMaster. These machines cut and bend metal for manufacturers of air conditioning and trade-show booths as well as for auto suppliers and many other types of business.

55,000 followers on Instagram

Software from TRUMPF helps the team quickly set up machines for different parts and carefully control the production process. “We love technology and we’re constantly investing in the digitalization of our business,” says Yost. In March 2023, PTL added a TruLaser Center 7030 to its portfolio, which Yost describes as a game changer. “Obviously, it took time to properly integrate the machine in our workflows,” he says. Ultimately, however, the new purchase has given the job shop a major edge over its competitors. “In future, we’ll be able to run automated production around the clock with a team of just 25 people.” Precision Tube Laser put an emphasis on digital marketing from day one, with Yost successfully harnessing Instagram and YouTube to build a strong community and engage with potential customers. PTL’s videos and posts are packed full of expert knowledge, especially when it comes to optimizing part design. Obviously, a design has to look good, but PTL also needs to be able to transfer the exact geometry of the part to its machines. “It’s very much a dialog: we keep going over the design plans until we get to the point where we can machine the metal,” says Yost. Thanks to this close collaboration, Precision Tube Laser is a partner that customers feel they can trust.

Industry goes digital

“When we first started out, we often had our backs against the wall! There were plenty of ups and downs, but we just had to grit our teeth and get through them,” he says. “As a result, we managed to find a profitable niche that’s allowed us to grow and improve year after year.” Today, PTL receives anywhere between 200 and 300 email inquiries a day. Between 30 and 50 of these are channeled into orders with volumes ranging from one-off pieces to batches comprising tens of thousands of parts. This has helped the company consistently post annual sales in the millions. With the Las Vegas region accounting for less than five percent of its order intake, PTL’s customer base now stretches across the entire country, with orders coming in from every U.S. state. And demand is growing particularly fast on the East Coast. “Back in early 2023, we had a customer base of around 1,200 companies,” says Yost. “Now we’ve broken the 1,500 mark – and 95 percent of them are repeat customers.” The industry as a whole is undergoing a transformation, with companies eager to embrace new technical opportunities and digital solutions. “It feels great to be helping them along that path.”

Yost is keen to maintain his entrepreneurial focus and continue to move PTL forward. With such a high order volume, some might be tempted to double the size of the team, but Yost is determined to keep the workforce lean. By increasing its level of automation, Precision Tube Laser can certainly raise its game even further, but growth for growth’s sake is not on the agenda. “This company feels like one big family where everyone looks out for each other – and that’s how I want it to stay,” says Yost with a grin.