Isidro Lobo pauses mid-sentence and turns around to search for something. The question that prompted this was about the values that drive his company. Moments later, the CEO of refrigeration equipment manufacturer Jordão plunges enthusiastically back into the conversation. In his hand, he’s holding a small plaque emblazoned with the following values: positivity, ambition, team spirit, integrity and excellence. It also includes the company’s mission: “Creating the best food preservation and display solutions, transforming challenges into solutions, and respecting the environment.” Everybody gets one of these plaques when they first join the company, and Lobo’s point is clear: Jordão doesn’t simply preach its values, it proudly displays them to its employees from their very first day at work.

The company was founded in 1982 by José Júlio Jordão in the city of Guimarães, in northern Portugal. What started out as a team of 22 people has since grown more than tenfold to a workforce of 250. Today, Jordão is one of Europe’s leading manufacturers of standard and tailored refrigeration equipment for food retail and the hospitality sector with customers all over the world and a most recent turnover of 21.5 million euros.

Jordão stands for innovation and for uniting technology and sustainability. The company offers digital, efficient and environmentally friendly solutions that help clients to reduce their energy consumption and to display food items. Last fall, one of its products even won an innovation award at one of the world’s most important fairs for the gastronomy and hospitality industry.

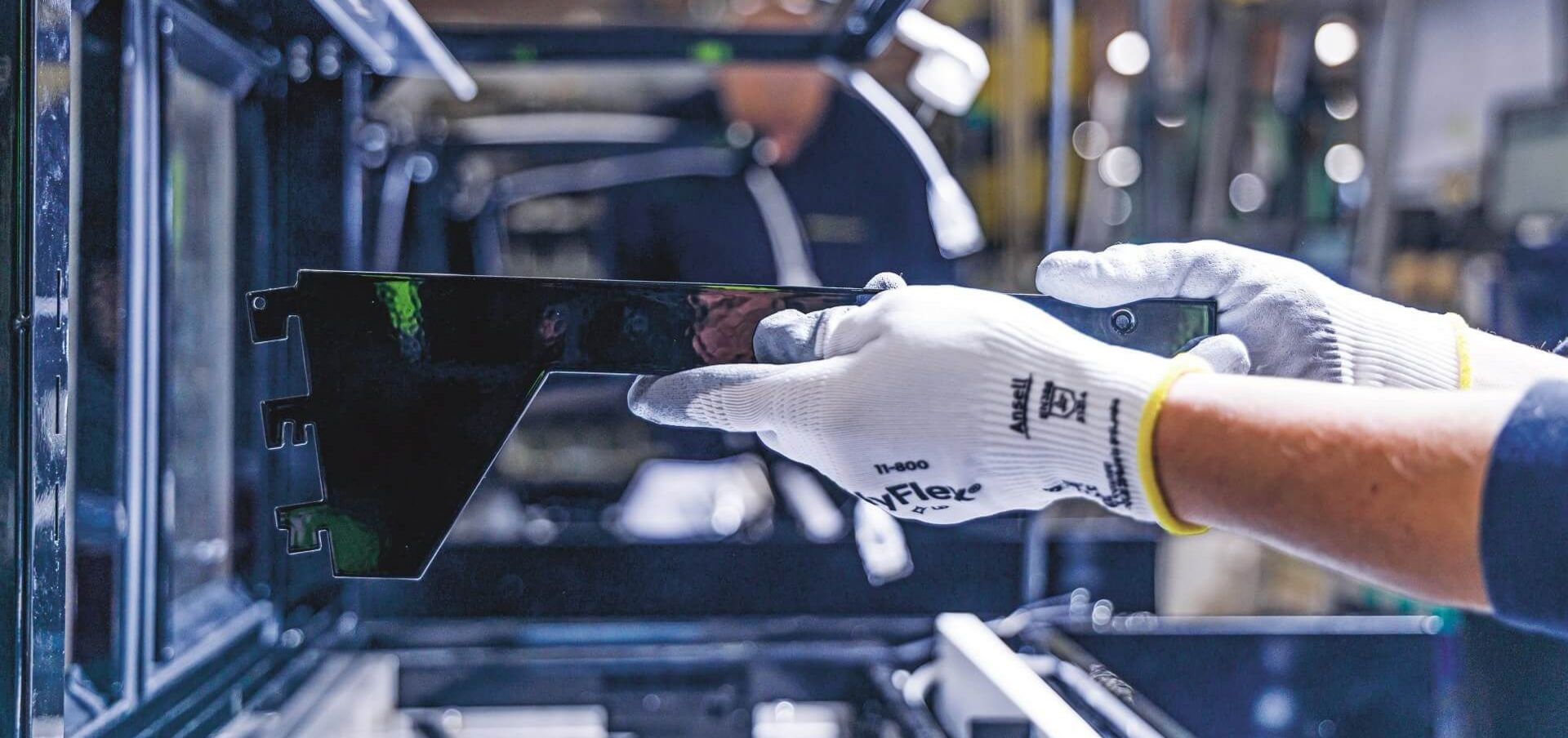

In 2021, the company entered into a partnership with TRUMPF. Jordão was looking for a machine to automatically bend small metal parts for refrigerated counters more quickly, and the TruBend Cell 7000 from TRUMPF proved to be the perfect fit. As well as their shared business interests, the two companies are both family-run enterprises and enthusiastic drivers of innovation. These common traits laid the foundations for a long-term partnership. Recently Jordão added a TruLaser 3040 fiber 2D laser-cutting machine, followed by a TruStore compact storage system. Paired up with the LiftMaster Compact and the PartMaster, the system cuts parts fully automatically in Jordão’s refrigeration equipment production facility.

Both the TruBend 7000 Cell and the TruLaser 3040 are easy to program and offer high productivity and part quality – and that’s a combination Jordão values. As well as saving the company time and money, the new system also requires less manual rework thanks to the high part quality, which eases the pressure on workers.

Continuity and loyalty on all sides

Yet long-term success does not depend on modern machinery alone. “You need people to be in a good mood when they come to work,” says Lobo. At Jordão, management helps foster this positivity by demonstrating consistency in everything they do. This Portuguese family business is not one for making rash or hasty decisions. It’s all about continuity, a value embodied by Lobo himself. He has been running the business for over 40 years. In future, the company will remain in the hands of an experienced team.

Equally long-term is the company’s partnership with TRUMPF. Jordão quickly realized that the high-tech company could not only help them make high-quality products, but could also offer them a productivity boost. Just like in Germany, Portuguese companies are struggling with a lack of skilled workers.

Automating processes with TRUMPF machines is therefore essential in order to remain competitive. Jordão is now also planning to introduce TRUMPF’s Oseon software for production control. This will help the company take automation to the next level and improve the flow of materials.

Ambitious goals

Jordão has set itself ambitious goals for the future. “Our goal is to double our turnover between 2022 and 2026,” says Lobo. Jordão is already on course to achieve that. It has purchased two buildings next to its existing site which provide 10,000 square meters of new production space – the biggest investment in the company’s history. This was important to align with Jordão’s growth strategy.

Customers are showing increasing interest in the company’s tailored refrigeration equipment solutions. “The retail food sector has taken on particular significance recently,” says Lobo, while emphasizing the continued importance of customers from the hospitality sector such as hotels, restaurants, and cafes. Jordão has also been building capacity to kit out smaller supermarkets.

As a major supplier and user of digitally connected manufacturing solutions, TRUMPF offers everything Jordão needs to achieve new heights in productivity through automation, providing the right high-tech support to help the Portuguese company grow. The benefits are neatly summed up by TRUMPF sales engineer Carlos Silva: “Jordão understands we have the skills to meet challenges head-on”.