TRUMPF Technology Center in Costa Mesa, CA

Bringing the fabrication know-how and state-of-the-art products of TRUMPF closer to our customers on the West Coast, the facility at Costa Mesa includes a full fabrication shop for technology demonstrations and applications consultation. With in-house training classes and technical service resources also established here, this facility provides complete customer care locally for the Western United States and Canada.

Schedule a visit today!

Contact our team today to schedule an in-person or remote machine demonstration!

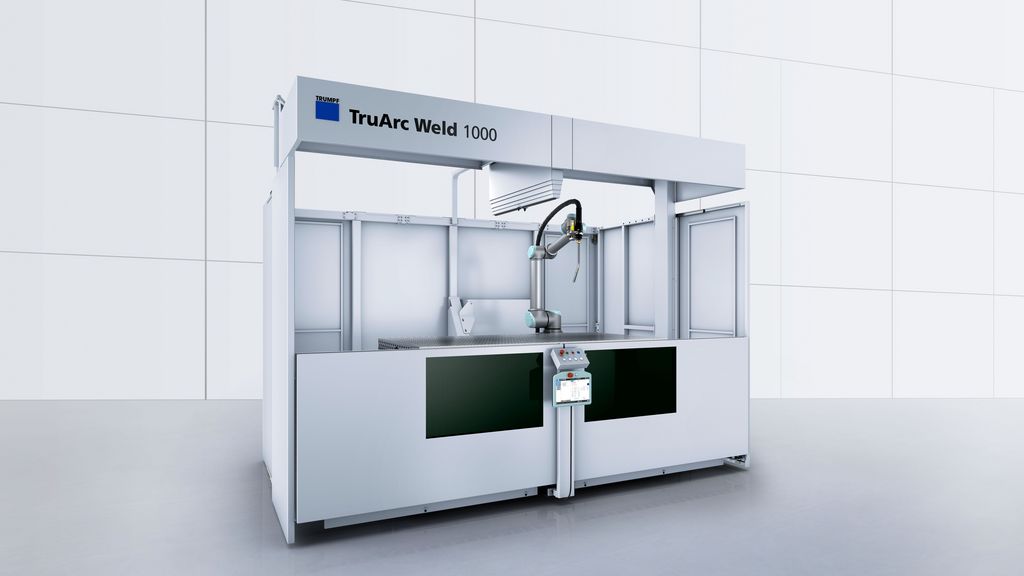

Machines Available for Demonstration

Baidu Maps is not displayed as you have not agreed to our use of cookies. Please change your privacy settings accordingly.

Map is not available.

Contact