We want to reduce site-related emissions (Scope 1 and 2) by 55 percent by 2030 compared to the base year 2018/19.

How do we reduce emissions at our sites?

We use green electricity at all of our sites.

We meet 100 percent of our electricity needs using renewable energies. Preferably through long-term contracts to support the expansion of new green power plants.

We are producing more and more green electricity ourselves.

By 2027, we want to equip all suitable roof areas at our sites with photovoltaic systems and are also examining the use of geothermal and wind power.

We improve the energy efficiency of our buildings.

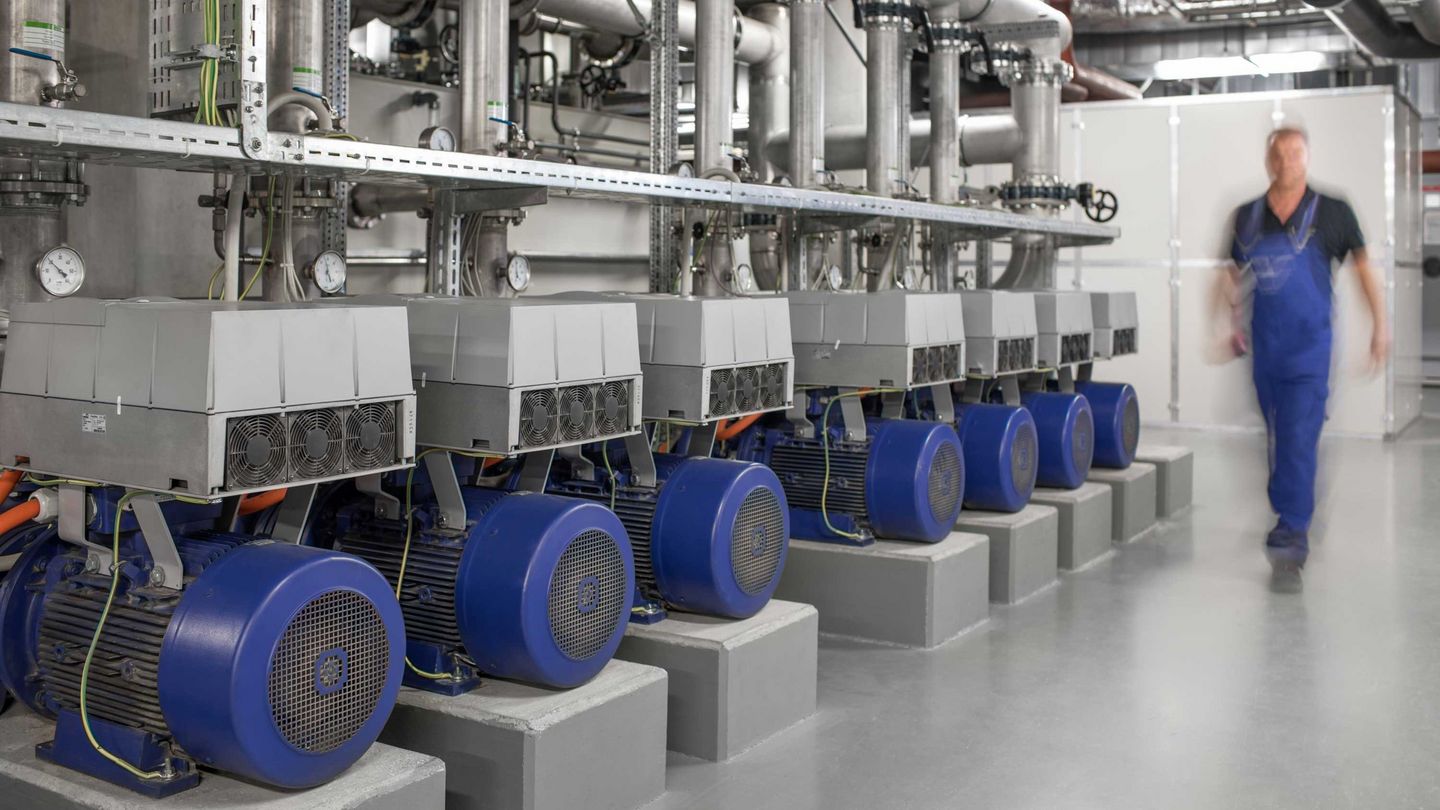

We use waste heat from our production for heating. In addition, we continuously optimize the power input of our heating systems.

We are replacing combustion engines with electric cars.

We are electrifying our vehicle fleet and want to reduce the CO2 emissions produced by the fleet by 50 percent by 2030 compared to the 2018/19 fiscal year.

Contact