Satellite thrust nozzle

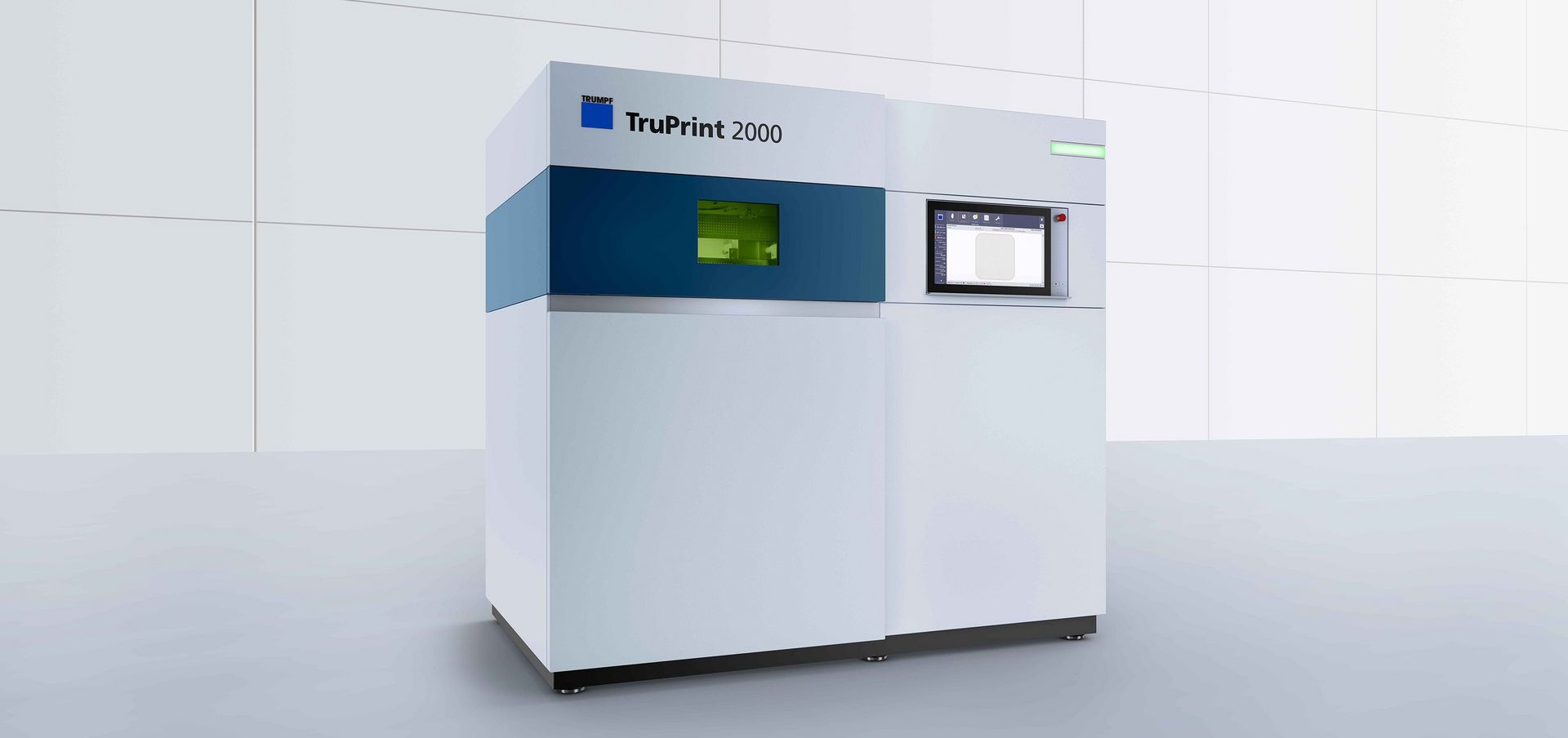

Additive manufacturing enables ultra-efficient and cost-effective production of power units for satellites or other load capacities. The option to produce components using niobium means they can be used in extreme temperature ranges from -150°C to > 1000°C. The company Agile Space Industries uses TruPrint 2000 for the 3D printing of thrust nozzles, saving on material and weight. 3D printing is particularly sustainable when using rare raw materials and expensive alloys. The thrust nozzles are used by satellites to align and maintain their position, by landing modules to touch down, and by rockets to adjust their flying direction.

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures about the example part

Material: Pure nickel or niobium (C-103)

Weight: 622 g

Construction duration: Single laser 13 h 39 min, multilaser 10 h 47 min

Number of layers: 4414 each 40 µm

Created by: Agile Space Industries