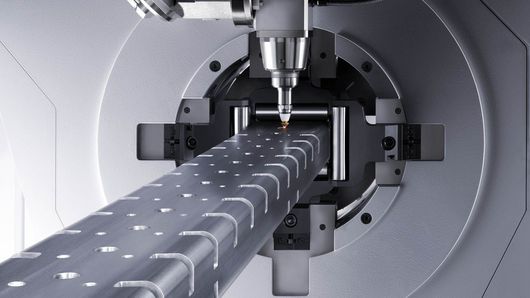

A comparison between laser cutting, plasma cutting and autogenic flame cutting

Different cutting procedures are available to manufacturing companies for cutting metallic materials. The three most common procedures are highlighted on this page: the laser as a tool stands out in direct comparison with plasma cutting and autogenic flame cutting, thanks to its high degree of precision and its working speed – even for non-metallic materials.

| Icon Laser cutting | Icon Plasma cutting | Icon Autogenic flame cutting | |

|---|---|---|---|

| Conventional area of application |

|

|

|

| Sheet thickness range | From 0.5 mm to over 30 mm | Hand-operated up to 38 mm; computer-controlled up to 150 mm**with extremely high energy input | From 1 mm to 1,000 mm |

| Quality | Low edge roughness and burr formation; very little spatter residue; hardly any post-processing required, depending on the sheet thickness | A great deal of spatter residue; very wide joins; a great deal of post-processing (for example, deburring) required | A great deal of spatter residue; very wide joins; a great deal of post-processing required |

| Productivity | High working speeds with a low-maintenance system; fluid process sequence | Very dependent on contour and requirements; process reliability is not always ensured - for example, the hole diameter for aluminum and stainless steel must be at least three times larger than the sheet thickness for a reliable process | Low productivity as it is usually a hand-operated process which consequently takes longer; metal must first be heated up |

| Precision | Extremely fine light beam; the most delicate of contours are possible | Relatively thick beam; delicate contours are not possible | High heat input, therefore less precision possible |

| Speed | Very fast (several meters per second) | Fast for bevel cuts in thick sheet metal | Slow (for example, up to 750 mm/min for a 10 mm thick sheet, as the metal must be preheated) |

| Contour flexibility | Very high. Small kerf of < 0.5 mm with accurate angles and very small holes | Low. Large kerf of 1 mm to 4 mm, no inner contours with sharp angles, imprecise and "rounded" corners, smallest hole size must be one to three times larger than the sheet thickness, high heat input | Low. No small holes or detailed shapes; large, rough shapes are more likely. Permits steep angles of up to 70° (compared to 45° for plasma) due to the concentration of the oxygen jet |

| Sustainability of the technology | Very high. Laser cutting is an innovative technology which is constantly being developed further. Each laser can be used to cut two- and three-dimensionally, with several axes and different material. Tubes and profiles can also be processed. | High. CNC plasma cutting systems can be used in a variety of ways. It is possible to cut two- and three-dimensionally with several axes. Tubes can also be processed. | Low. The technology can no longer be adapted for new cutting requirements. One reason is because only a few variables (for example, the nozzle) can still be further developed and improved. |

Contact