Perfect cuts straight away

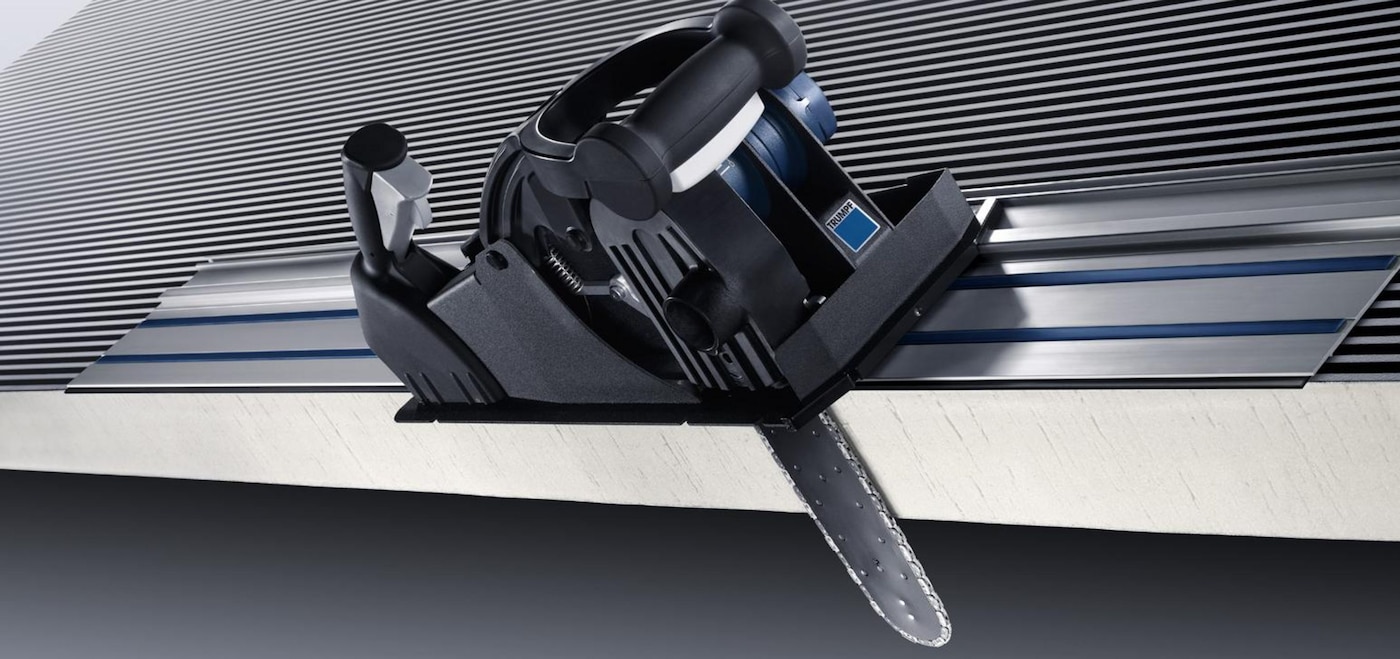

With the TruTool TPC 165 panel cutter, you can cut sandwich panels up to a thickness of 6.5 in. The blade insertion mechanism enables the production of accurate, perpendicular interior cutouts and notches. In one operation. The machine is ready for operation without presettings. Simply select the correct blade position and begin cutting. The TruTool TPC 165 can cut panels regardless of whether the surface is flat, trapezoidal, or corrugated.

Swiveling 90° blade, well-suited for perpendicular cutouts with a depth of up to 6.5 inches.

With the insertion mechanism, you can start at any position on the panels.

You can cut the upper and lower sheets in one press operation, without the need for reworking.

The TruTool TPC 165 weighs just 9.6 kg and is based on a sheet design that is both stable and light.

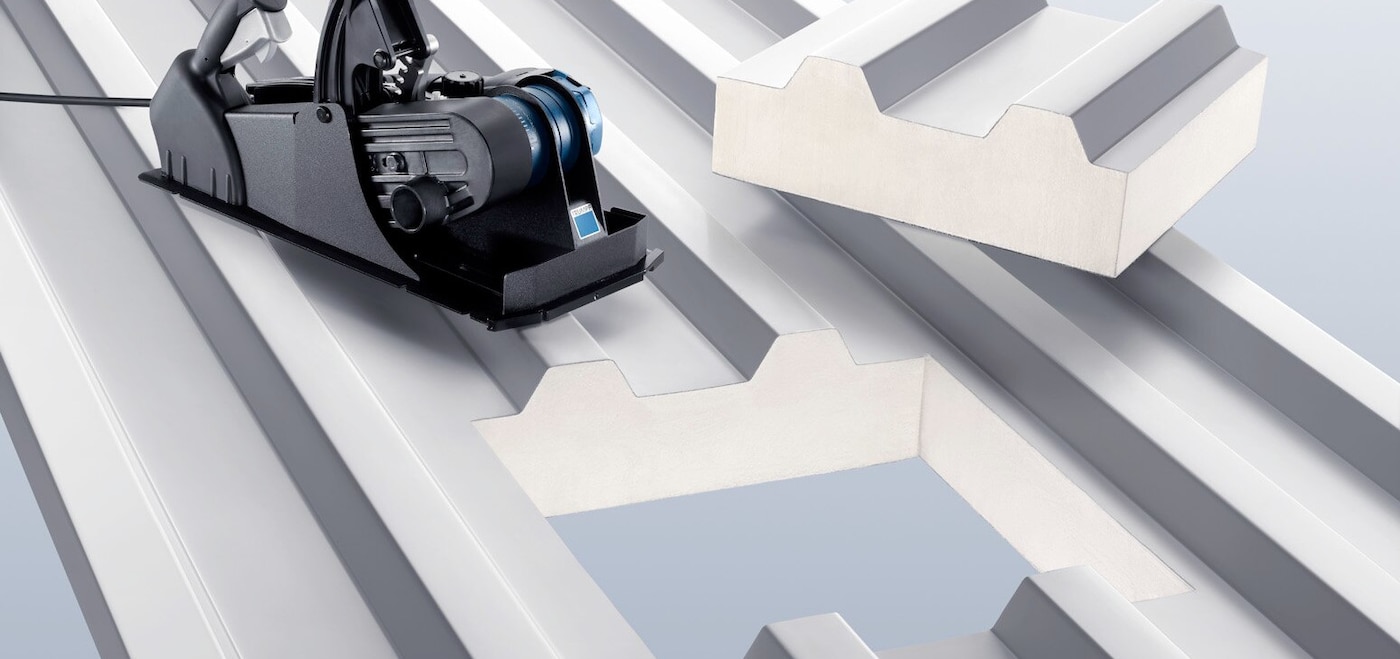

Flat sandwich panels

Roof panels. Steel or aluminum surface. Insulation material: Polyurethane foam, polyisocyanurate foam. For panel thicknesses up to 6.5 inches.

Corrugated sandwich panels

Roof panels. Steel or aluminum surface. Insulation material: Polyurethane foam, polyisocyanurate foam. For panel thicknesses up to 6.5 inches.

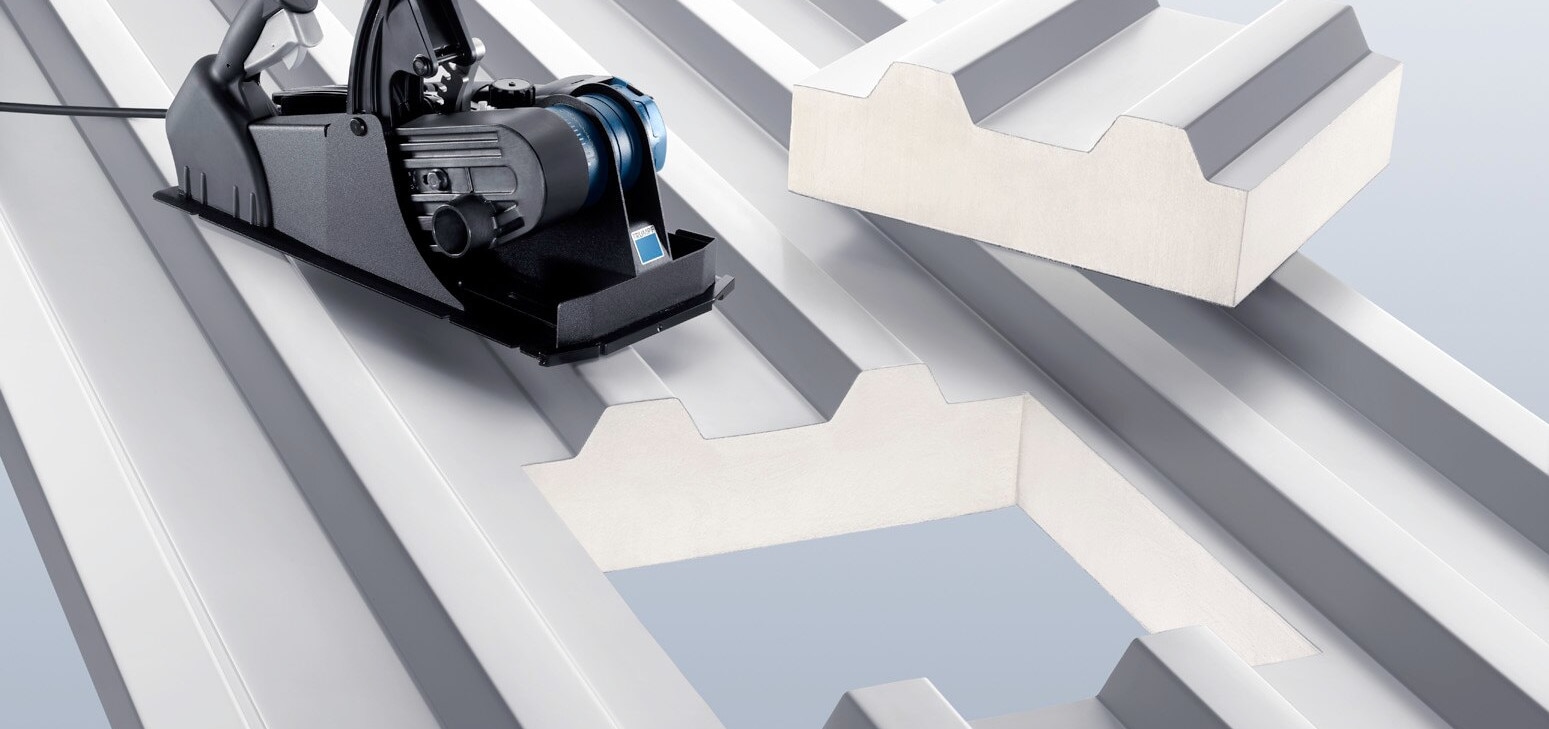

Trapezoidal sandwich panels up to 6.5 inches deep

Roof panels. Steel or aluminum surface. Insulation material: Polyurethane foam, polyisocyanurate foam. For panel thicknesses up to 6.5 inches.

The following consumables and the corresponding accessories are included in the scope of delivery.

Find the right consumables and accessories for your machine here.

For guide rail

55 in. length

Perpendicular cuts

Unique

Simple tool change

|

TruTool TPC 165

|

|

|---|---|

| Panel cutter | |

| Maximum panel thickness | 165 mm |

| Maximum individual material thickness for steel up to 400 N/mm² | 0.9 mm |

| Insulation material | Polyurethane foam, polyisocyanurate foam |

| Smallest possible opening by piercing | 340 mm x 340 mm |

| General | |

| Working speed (max.) | 4 m/min |

| Cutting track width | 4 mm |

| Nominal power consumption | 1600 W |

| Dimensions | |

| Length | 493 mm |

| Height | 231 mm |

| Weight | |

| Weight | 9.6 kg |

The technical data of all product versions as a download.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.