Cost-effective entry-level machine

The TruPunch 1000 Prime Edition excels with its high level of processing flexibility. In addition to just punching, you can also use it to form threads, extrude, and bend flanges. You can process midsize sheets completely in one tool setup without repositioning. You can even produce smaller orders and lot sizes economically, quickly and with flexibility.

The TruPunch 1000 Prime Edition masters all of the relevant applications of a TRUMPF punching machine.

The intuitive control enables the immediate production of simple and complex parts.

TRUMPF offers top quality punching tools such as the MultiTool or the MultiShear slitting tool.

Electronic component

Produce with flexibility using tools for every application, for example, flanges, cups, roller folding.

For this component, the following tools were used: stepping tool, bracket tool, cup tool rectangular and round, offsetting roller tool, and pinching roller tool

Workpiece

With the largest tool range in the world, the machine offers the highest level of processing flexibility.

For this workpiece, the following tools were used: roller beading tool, MultiCut tool, cup tool, and roller offsetting tool.

|

TruPunch 1000 Prime Edition medium format

|

|

|---|---|

| Dimensions | |

| Width | 6550 mm 1 |

| Depth | 7144 mm 1 |

| Height | 2155 mm 1 |

| Maximum stroke rate | |

| Punching (E = 1 mm) | 600 1/min |

| Marking | 1300 1/min |

| Working range | |

| Punching mode, X axis | 2500 mm |

| Punching mode, Y axis | 1250 mm |

| Maximum sheet thickness | 6.4 mm |

| Maximum workpiece weight | 150 kg |

| Maximum punching force | 165 kN |

| Tools | |

| MultiTool tool changing time | 2.4 s |

| Number of tools/clamps | 18 pieces / 2 pieces |

| Part removal | |

| Maximum part size, part removal flap, punching | 180 mm x 180 mm |

| Maximum part size, part removal flap, punching (with moving table) | 180 mm x 500 mm |

| Maximum part size, fixed chute, punching (with moving table) | 460 mm x 500 mm |

| Consumption values | |

| Average power input of active auto-shutdown | 0.3 kW |

| Average power input in production | 4.3 kW |

The technical data of all product versions as a download.

The TruPunch 1000 Prime Edition guarantees you the best part quality with a high level of efficiency. Common cuts lower the amount of scrap and make optimum use of the material.

Ball tables or brush tables are available for gentle material handling.

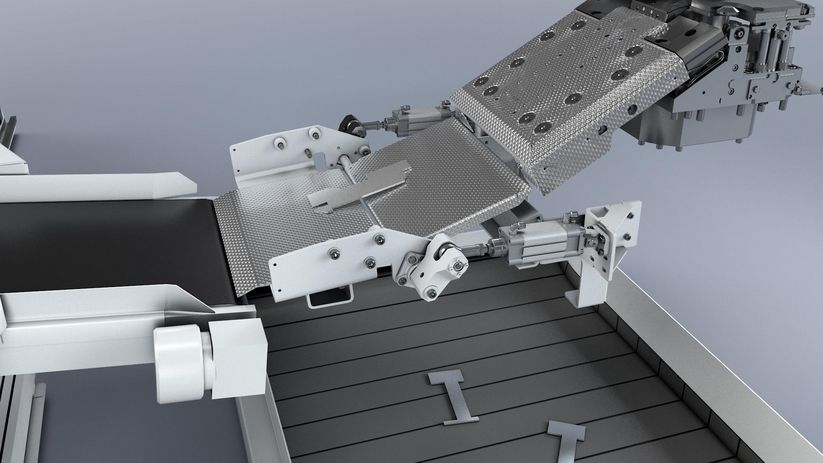

With the parts conveyor belt, punching parts are ejected in a process-reliable way.

With the blank processing package, you can also process blanks simply and in a process-reliable way. This is made possible by a second index pin and additional clamp, amongst other things.

As a result of the On-Demand Drive, the hydraulic punching head system always works to the optimum level. This leads to reduced noise generation during non-productive times and reduces the hydraulic load of the entire system.

TRUMPF is the first manufacturer worldwide to offer punching machines that feature skeleton-free processing. This innovation saves material and increases process safety.

TruTops Boost

Construct and program your laser, punching, and combination punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Software

The extensive range of TruTops software supports you throughout the entire production process. Control your operational workflow in a simple and targeted manner, from managing your customer orders and purchasing processes to delivery of the produced parts. Through the direct coupling with the machine control, you can keep a constant eye on the status of your orders.

You can boost the productivity of your punching machine with a tool adapter for up to ten inserts – in particular for small punching operations.

Use our patented cutting technology for outstanding edge quality without nibbling marks. A die with brush inserts also prevents scratches.

You can use the roller technology to create straight and curved beads of any length in the sheet. This produces high-quality workpieces without visible forming marks.

The cost-effective alternative for punching, where you can be sure that the machine, software, and tool are perfectly coordinated with each other.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

The dimensions are approximate; the dimensions specified in the installation plan are valid.