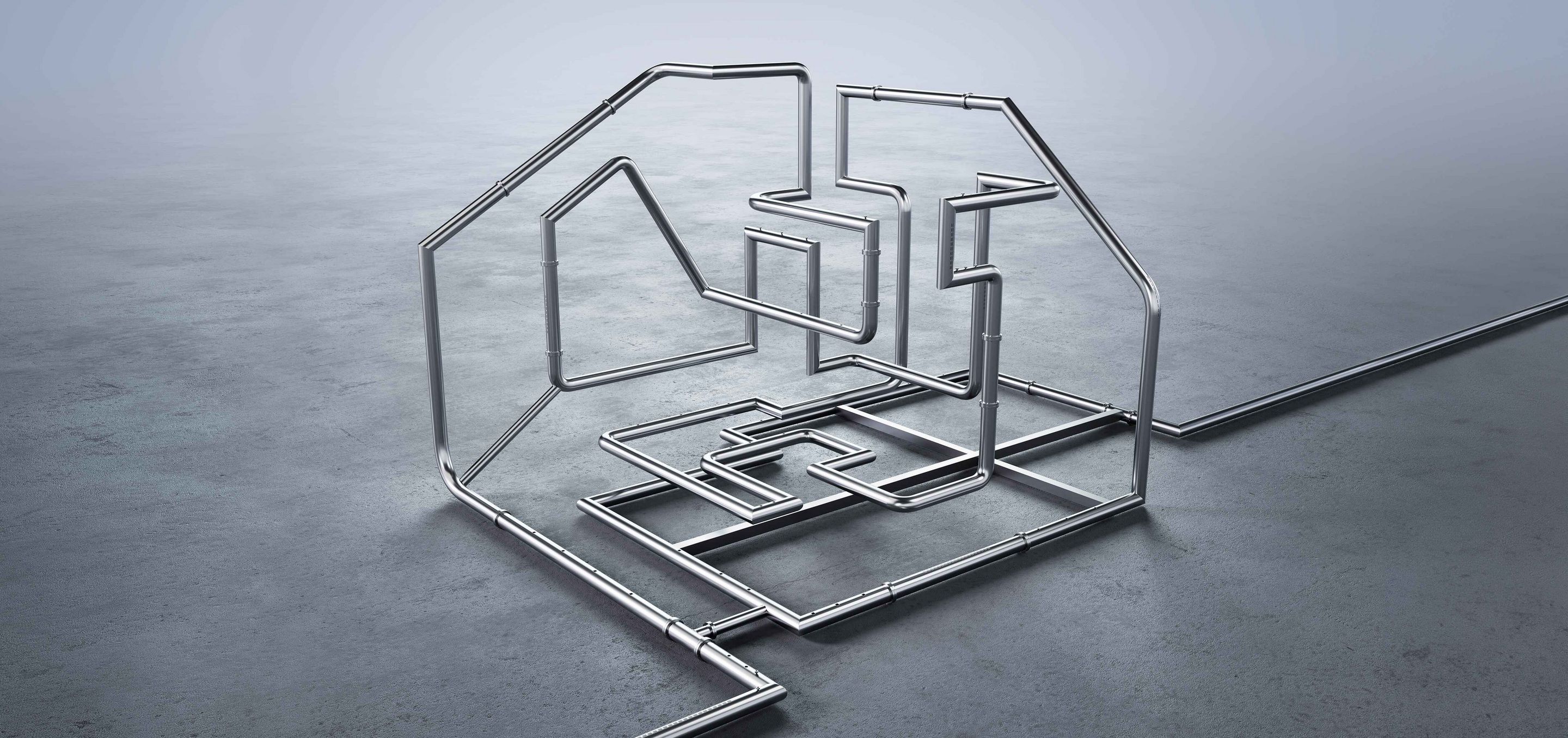

Allow a vision to come to life with tubes and profiles in vehicle frames, in furniture and lamps, as well as in mechanical and plant engineering, for example. A fully automated tube processing chain helps you to tackle any skills shortages, reduce your high costs, and develop new business opportunities. TRUMPF will provide everything you need to achieve this. The full package. When will you invest in limitless options from a single source?

Your challenges in the tube processing sector

What does your perfect tube processing chain look like?

Increased security thanks to seamless support of the entire process chain

The tube processing chain consists of storing, processing, and welding. It can be automated precisely based on your requirements. A fully automated process chain comprises up to 7 steps: storing, loading, laser tube cutting, unloading and sorting, tube bending, 3D laser cutting, and welding. Our software and service solutions simplify the process. Of course, you can also only partially automate the process steps. It is up to you – design your perfect process chain with us.

Overview of the process steps

1. Storing

The right store solution for your raw material and more storage space. The STOPA store and our Oseon production control will help you to structure your store and save on search times.

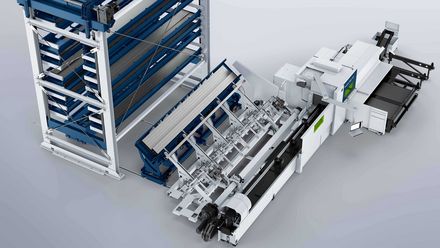

Find out more2. Automated loading

Fully automated loading of your laser tube-cutting machine: The machine requests raw material via an interface and is loaded directly from the store cartridges.

Find out more3. Laser tube cutting

Design complex contours and new tube designs using cost-effective, efficient, and flexible technology that prevents reworks and errors.

Find out more4. Automated unloading and sorting

Automated unloading and sorting via the unloading automation interface with longitudinal conveyor belt. This reduces operator involvement, errors, and costs.

Find out more5. Tube bending

Highly efficient and accurate CNC tube bending technology reduces component costs, and prevents welding and soldering work. We rely on transfluid® as our partner.

Find out more6. 3D laser cutting

A TruLaser Cell system will enable you to integrate complex geometries into bent tubes both in bending zones and final cuts.

Find out more7. Welding

Automatic arc welding ensures the productive and reliable joining of components. Automatic laser welding also saves you time and money.

Find out moreModules for your fully automated tube processing production solution

We can provide the perfect components from a single source for every process step: Fully automated or a combination of automated and manual modules. Your solutions can thus range from a separate stand-alone machine to a complete automated system – tailored exactly to your needs. In addition, you will receive the appropriate software and services.

Overcome the challenges

The advantages of a fully automated tube processing production solution

Automated processes will ensure you require fewer qualified specialist staff.

Reduce risk of errors and increase productivity and efficiency with automated processes.

Reduce cost pressures with strategic purchasing and reduced throughput times.

Counteract a lack of space by using vertical stores and optimizing your use of space.