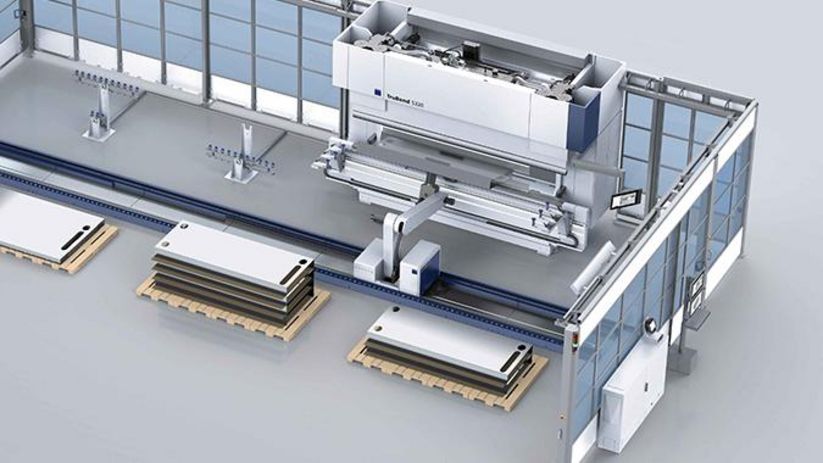

Cost-effective productive bending cell

The TruBend Cell 5000 Lean Edition can be programmed in no time at all for fast, precise bends. It is ideal as productive and flexible automation for a wide range of parts. Produce high-quality bends with ease - thanks to intuitive programming and simple gripper changes.

The TecZone Bend programming software performs calculations quickly and is easy to operate.

Use the gripper and vacuum gripping technology to bend small and medium parts as well as parts weighing up to 40 kg.

The automatic gripper change saves time.

A sheet sensor helps the gripper to pick up the blanks correctly.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.