This year’s in-house exhibition will focus on sustainability // TRUMPF to showcase solutions designed to cut the use of materials, energy and chemicals in production.

INTECH 2023 – TRUMPF in-house exhibition: Making manufacturing more sustainable

Ditzingen, March 22, 2022 – German high-tech company TRUMPF is using its annual INTECH in-house exhibition to showcase solutions designed to boost sustainability and productivity in connected manufacturing. Alongside technologies to lower the consumption of materials, energy and cutting gas, the exhibition will also feature processes to reduce or eliminate the use of environmentally harmful chemicals in automotive manufacture.

Lower emissions, higher productivity

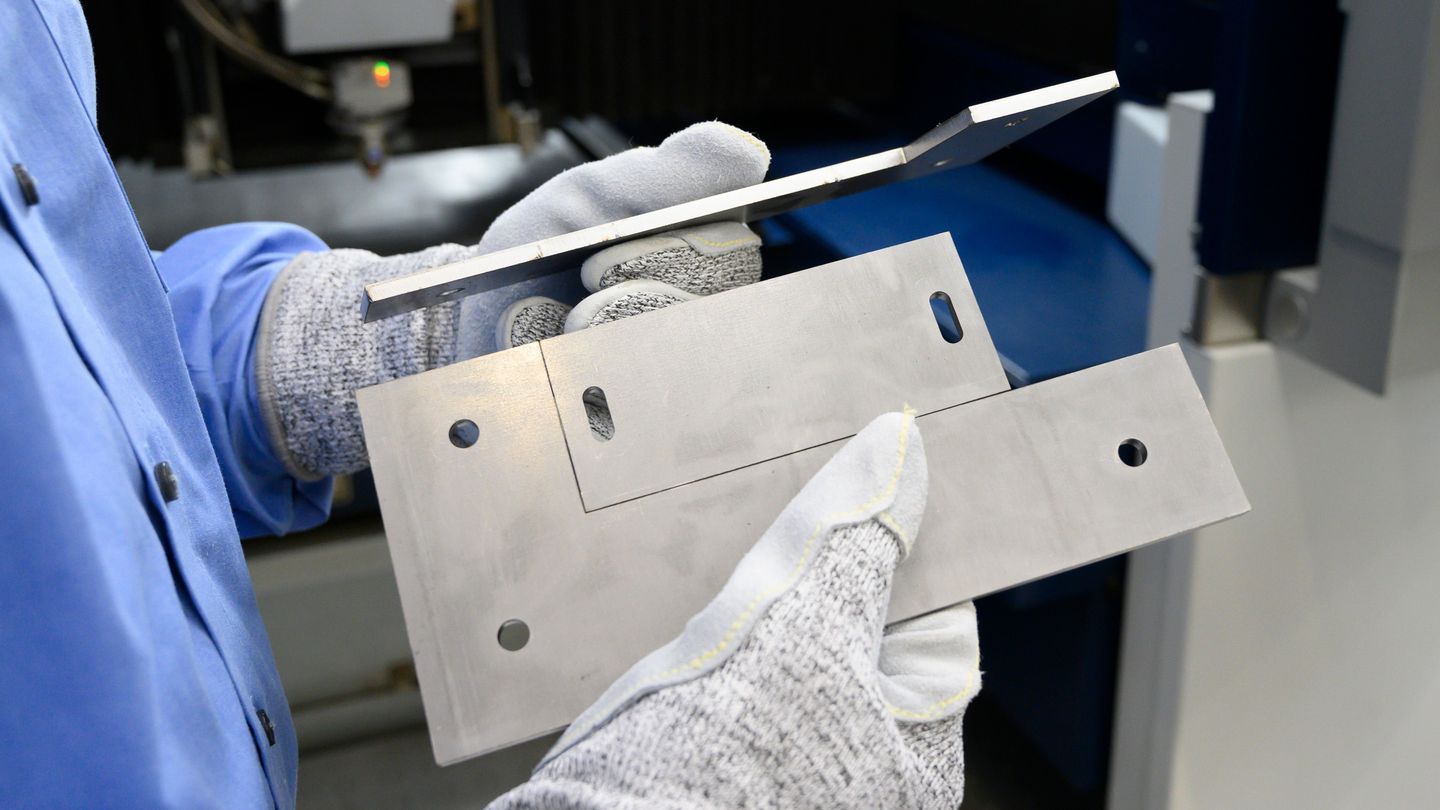

New developments on show at this year’s INTECH include the Eco Cooler, an innovative technology that uses nothing but pure water to cool TRUMPF laser-cutting machines. This reduces energy consumption for refrigeration by 80 percent and dispenses entirely with environmentally harmful refrigerants. TRUMPF is also showcasing Highspeed Eco, a process that reduces gas consumption in laser cutting by as much as 60 percent. Other exhibits will present technology designed to reduce the use of materials in manufacturing. Among these is the nano-joint process, which substantially reduces the size of the retaining tabs that connect parts to the sheet from which they have been cut by laser. This means that parts can now be nested right next to one another, thereby reducing the amount of waste material in the skeleton.

Making automotive manufacture more environmentally compatible

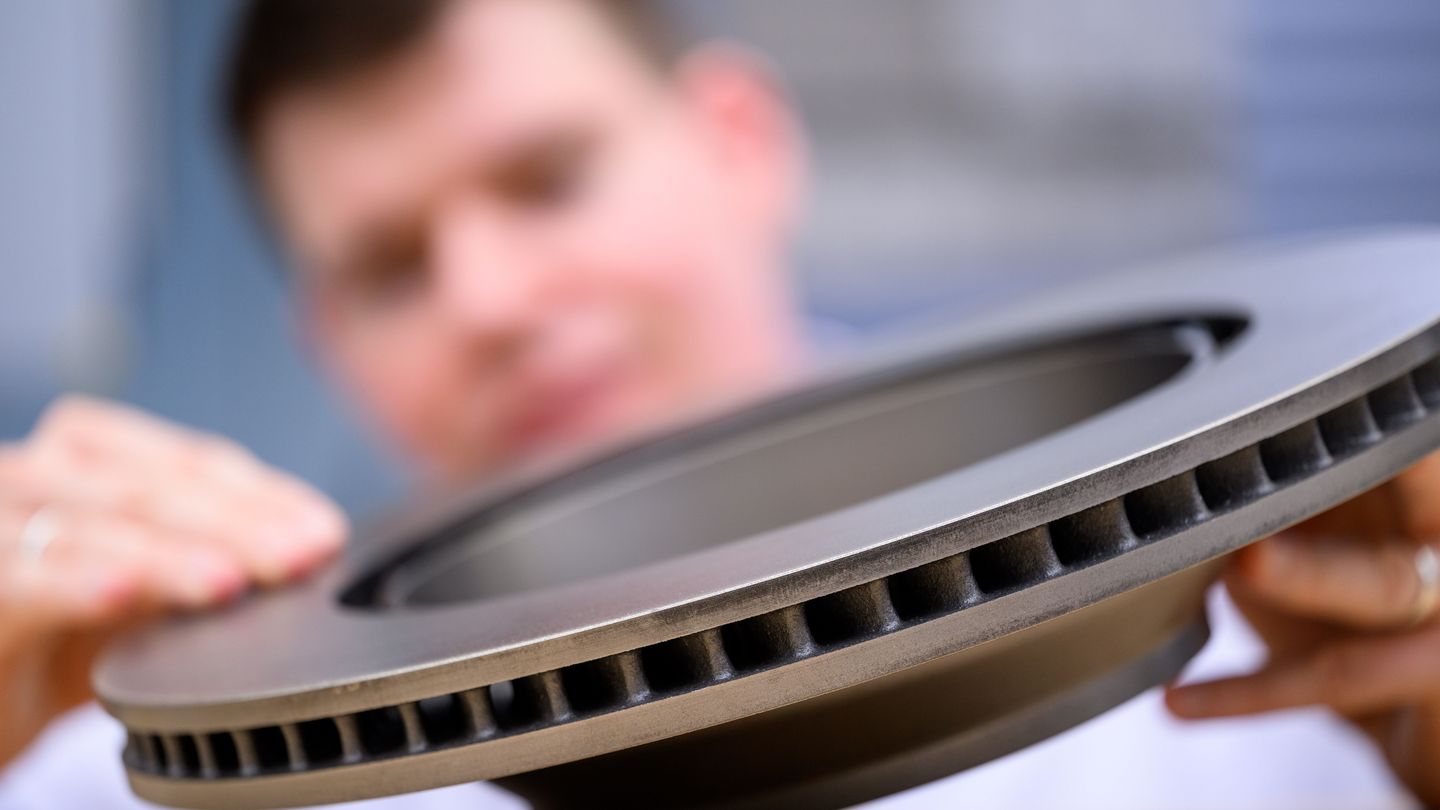

At this year’s INTECH, TRUMPF will be demonstrating how laser technology can help automakers make their operations eco-friendlier. The company will be showcasing short-pulse lasers that eliminate the use of chemical cleaning agents in the industry. Unlike the conventional process, short-pulse lasers only clean components where it is actually needed. This not only saves water but also reduces the use of environmentally harmful chemicals. TRUMPF will also be demonstrating how the use of high-speed laser metal deposition (HS-LMD) – a technology that is now ready for industrial application – can help reduce brake-disc wear in road traffic and thereby particulate emissions. Even very low concentrations of particulate matter are harmful. About half of the particulate emissions produced by road traffic are due to the abrasion of vehicle brakes, tires, clutches and road surfaces. And around half of this matter is brake dust. Brake discs coated by means of HS-LMD produce far less particulate matter compared to conventional brake discs. Visitors at INTECH will be able to view this technology.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”. Graphic editing – except for cropping out the main motif – is prohibited. Additional photos can be accessed at the TRUMPF Media Pool.

Contact person