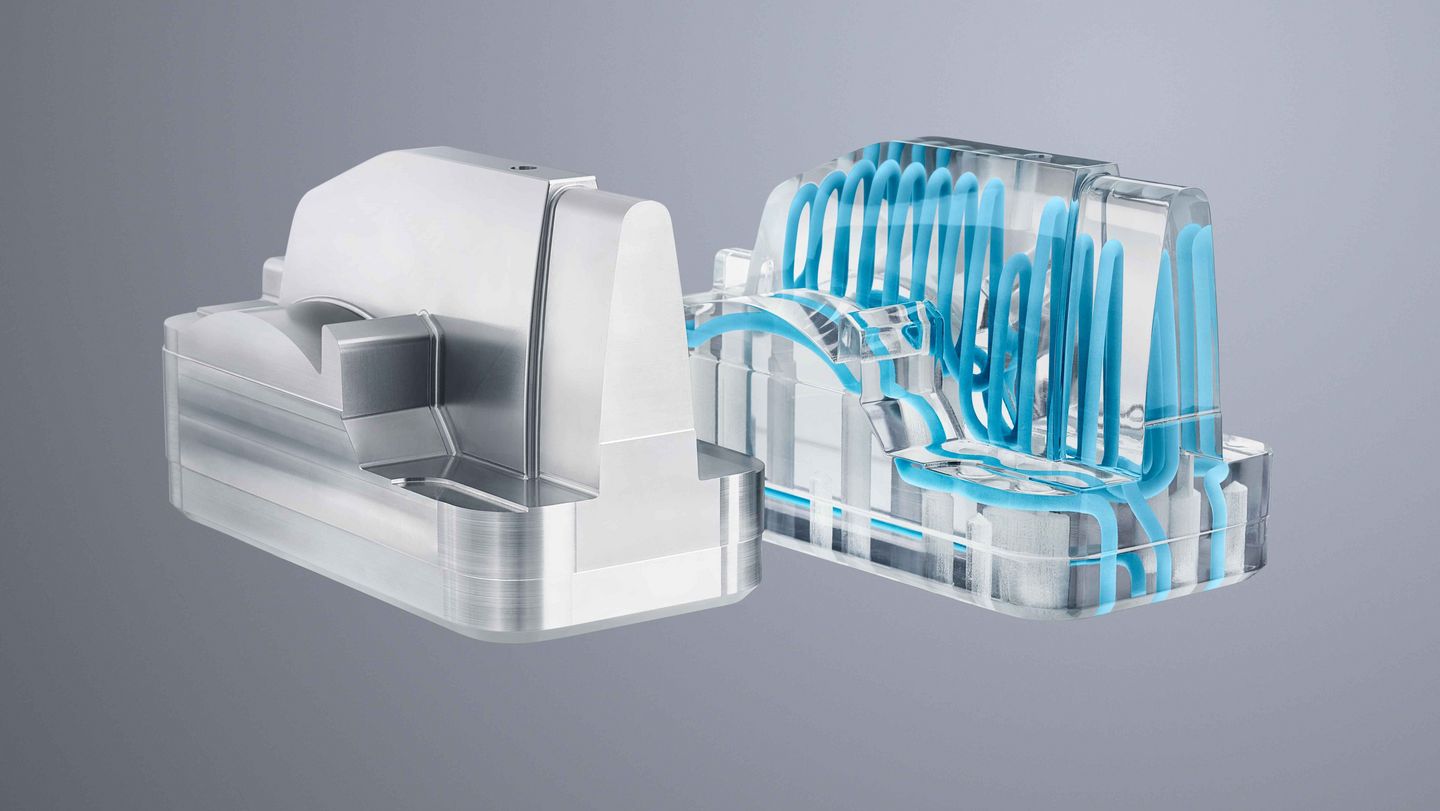

Conformally cooled tooling insert

This tooling insert demonstrates the safe and reliable processing of H11 tool steel, which is only possible with the 500 °C preheating feature of the TruPrint 5000. The freedom of design allows the cooling channels of the die-cast tool insert to run in curves instead of in sharp edges over the entire surface, so that dead areas and sealing plugs are avoided. Conformal cooling shortens the cycle time and improves the component quality. For the tooling insert, the pressure loss was reduced and the cooling time shortened by 28%.

Conformal cooling channels in combination with conventional tool steel

Crack-free

Density > 99.9%

Reduction of the cooling time by 28%

35% less distortion

Facts & figures about the example part

Material: H11 tool steel

Created by: Hermle

Find out more about the product

Contact