| Conventional area of application | - Metallic materials (mild steel, stainless steel, aluminum, copper, brass, foiled sheets, galvanized sheets)

- Non-meta... Mehr lesenllic materials (carbon, glass, plastics, wood, leather, etc.)Weniger lesen

| - Metallic materials (steel, stainless steel, aluminum, copper and brass, various conductive metals)

| - Metallic materials (mild steel and low-alloy steels, but not aluminum or stainless steel). Only metals whose oxides... Mehr lesen have a lower melting point than the base metal can be cut with this process.Weniger lesen

|

| Sheet thickness range | From 0.5 mm to over 30 mm | Hand-operated up to 38 mm; computer-controlled up to 150 mm**with extremely high energy input | From 1 mm to 1,000 mm |

| Quality | Low edge roughness and burr formation; very little spatter residue; hardly any post-processing required, depending ... Mehr lesenon the sheet thicknessWeniger lesen | A great deal of spatter residue; very wide joins; a great deal of post-processing (for example, deburring) required | A great deal of spatter residue; very wide joins; a great deal of post-processing required |

| Productivity | High working speeds with a low-maintenance system; fluid process sequence | Very dependent on contour and requirements; process reliability is not always ensured - for example, the hole diame... Mehr lesenter for aluminum and stainless steel must be at least three times larger than the sheet thickness for a reliable processWeniger lesen | Low productivity as it is usually a hand-operated process which consequently takes longer; metal must first be heated up |

| Precision | Extremely fine light beam; the most delicate of contours are possible | Relatively thick beam; delicate contours are not possible | High heat input, therefore less precision possible |

| Speed | Very fast (several meters per second) | Fast for bevel cuts in thick sheet metal | Slow (for example, up to 750 mm/min for a 10 mm thick sheet, as the metal must be preheated) |

| Contour flexibility | Very high. Small kerf of < 0.5 mm with accurate angles and very small holes | Low. Large kerf of 1 mm to 4 mm, no inner contours with sharp angles, imprecise and "rounded" corners, smallest hol... Mehr lesene size must be one to three times larger than the sheet thickness, high heat inputWeniger lesen | Low. No small holes or detailed shapes; large, rough shapes are more likely. Permits steep angles of up to 70° (com... Mehr lesenpared to 45° for plasma) due to the concentration of the oxygen jetWeniger lesen |

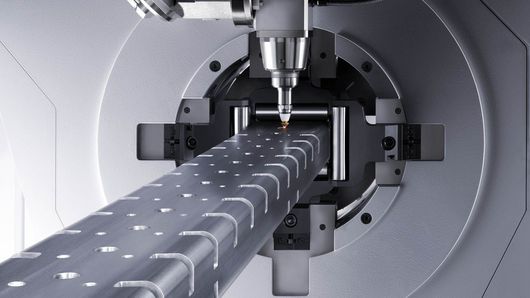

| Sustainability of the technology | Very high. Laser cutting is an innovative technology which is constantly being developed further. Each laser can be... Mehr lesen used to cut two- and three-dimensionally, with several axes and different material. Tubes and profiles can also be processed.Weniger lesen | High. CNC plasma cutting systems can be used in a variety of ways. It is possible to cut two- and three-dimensional... Mehr lesenly with several axes. Tubes can also be processed.Weniger lesen | Low. The technology can no longer be adapted for new cutting requirements. One reason is because only a few variabl... Mehr lesenes (for example, the nozzle) can still be further developed and improved.Weniger lesen |