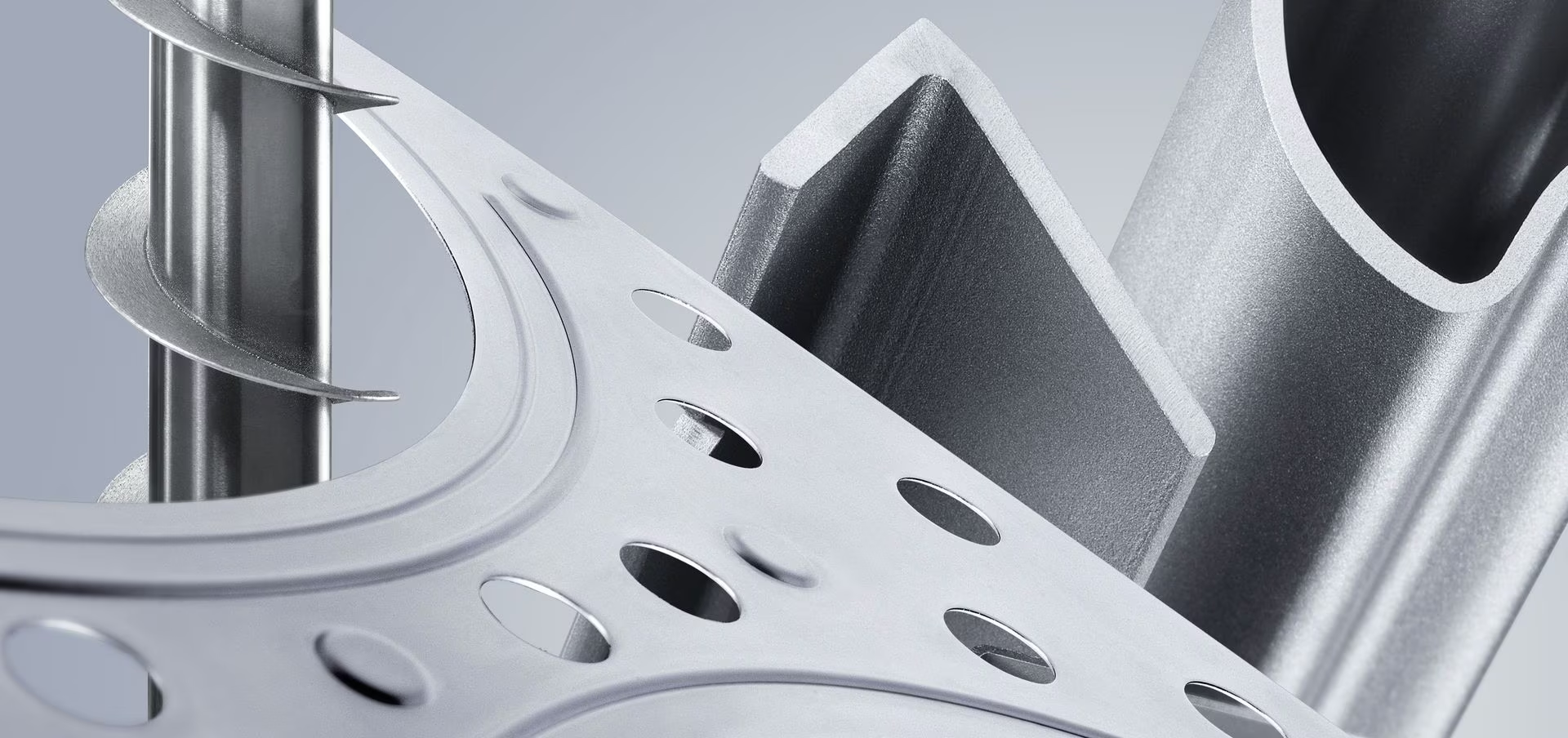

The right expertise for your project

Reliable, pioneering expertise in more than 50 areas of application

We have developed and produced tools for the manufacturing industry for decades. With this expertise, we can offer you tried and tested solutions to meet the needs of an extremely wide range of applications. Applications for TRUMPF lasers, machines, power tools, and power electronics can be found in a diverse spectrum of components across all industries. Regardless of whether you're looking for a reliable standard tool or a custom product – we can offer you comprehensive advice so that you can take advantage of all production possibilities.