A VCSEL (Vertical cavitiy surface emitting laser) is a laser diode that vertically emits light in a cone-shaped beam from the surface of a fabricated wafer. VCSELs offer many benefits in comparison with conventional edge-emitting lasers where light is emitted on one or two edges of the chip. Whether for the industry or the consumer market, VCSELs are available in different wavelengths. The standard wavelengths are in the range of 760 nm, 850 nm and 940 nm.

The advantages of the TRUMPF VCSEL

What is a VCSEL laser and what are its advantages compared to other laser diodes? What is the structure that makes the special functionality of VCSEL arrays possible in the first place? On this page you can also learn more about the two types of VCSELs as well as everything you need to know about the typical industrial and consumer applications of the laser diodes.

What is a VCSEL (vertical cavity surface emitting laser)?

What are the advantages of VCSELs?

The round beam, which can even be Gaussian in shape, the low beam divergence and the different light modes (multimode and single-mode) make VCSELs perfect for a variety of applications.

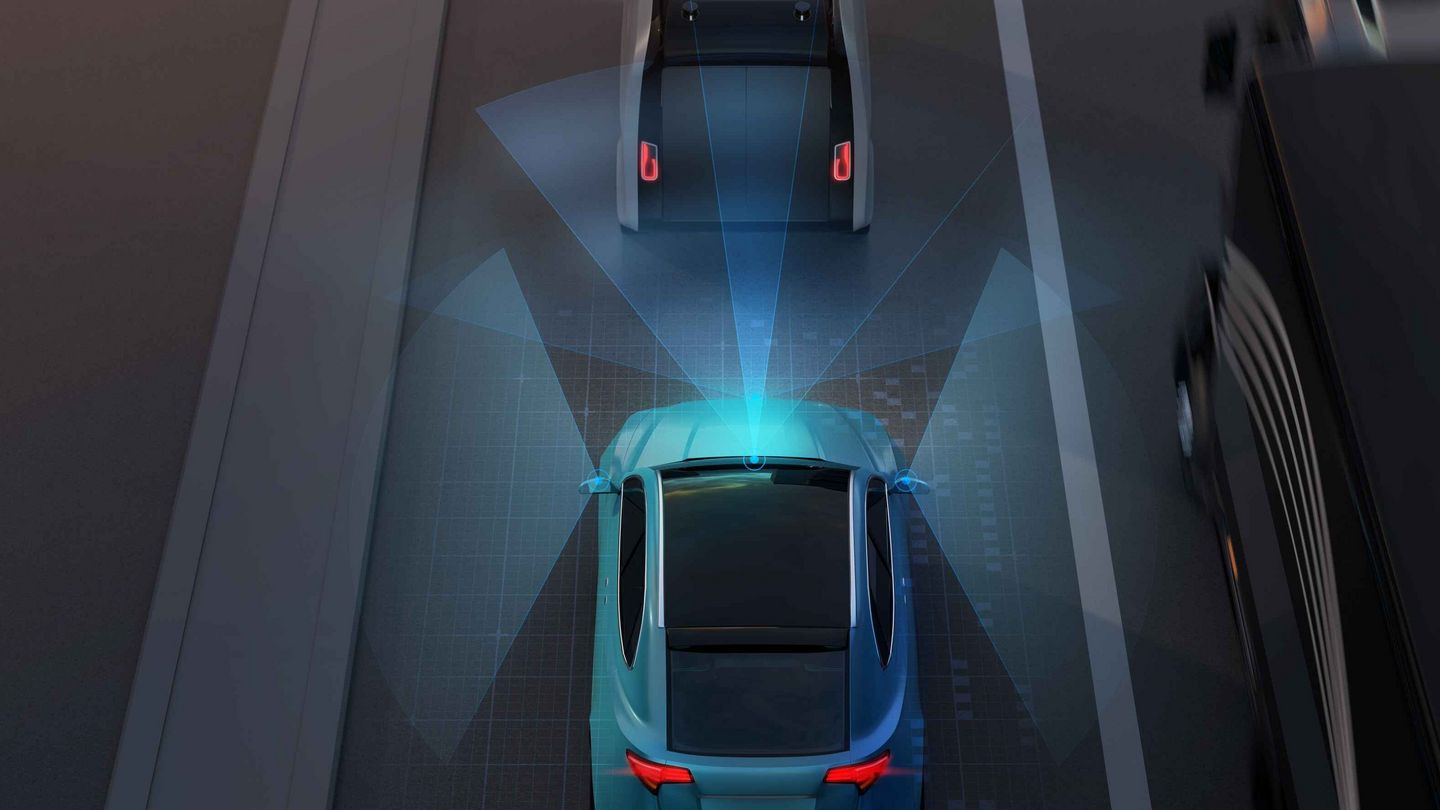

With their high modulation speeds, beam quality and energy efficiency, VCSEL arrays are ideally suited for high-tech applications such as 3D sensing, LiDAR or optical data communication.

The vertically emitting lasers can save on installation space and arrays with many emitters can be achieved with just one chip. This means high volume production and testing can be achieved at wafer level

The power input of the VCSELs in the very low milliwatt range enables very efficient operation in mobile applications, or even when used in data centers, while at the same time significantly reducing power consumption.

Thanks to short rise and fall times, very fast pulse operation is possible with VCSEL. This is particularly important for use in optical data communication and Time-Of-Flight (ToF) systems.

VCSELs enable spectral light emission with an extremely narrow bandwidth.

With the vertical light emission, additional features such as polarization-stabilizing elements or micro-optics can be easily integrated.

This is how a VCSEL works

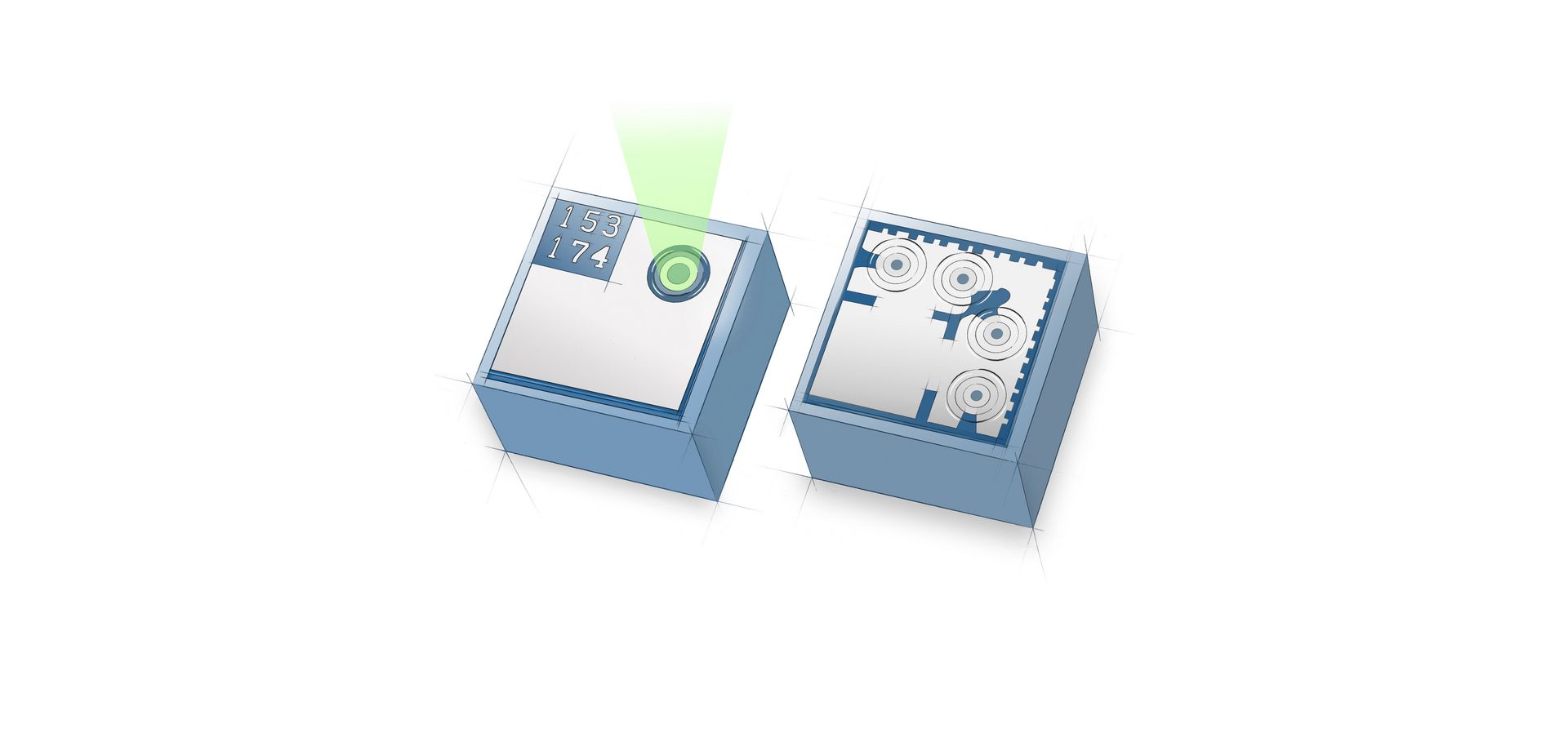

A VCSEL is made up of many epitaxial layers built on top of each other. The top layer is a contact layer for power input. The first of the two mirrors is below this. This is carbon-doped and is composed of multiple layers of AlGaAs with varying levels of aluminum. The reflectivity of the upper mirror is usually around 99 percent.

The oxidation layer comes after the upper mirror. This consists of material with a high aluminum content, which is partially passivated by wet oxidation. The inner (non-passivated) part of the oxidation layer is used for current constriction and optical guidance. The oxidation layer is responsible for defining many important electro-optical parameters of a VCSEL.

The active region contains the quantum wells. This serves to boost the power.

Below the active region is the second mirror, which is silicon-doped and significantly thicker than the upper mirror. This serves to reflect as much light as possible back into the active region. The reflectivity of the lower mirror is usually around 99.9 percent.

Single-mode VCSEL vs. multimode VCSEL: what are the differences?

Currently, there are two types of VCSEL: single-mode VCSELs and multimode VCSELs. A single-mode VCSEL produces a light beam with high spectral purity and exhibits lower divergence and higher coherence than a multimode VCSEL. While single-mode VCSELs are especially common in many industrial sensor applications, the compact multimode VCSELs are most commonly used in mobile consumer applications and highly integrated sensors.