Industrial TruHeat VCSEL systems

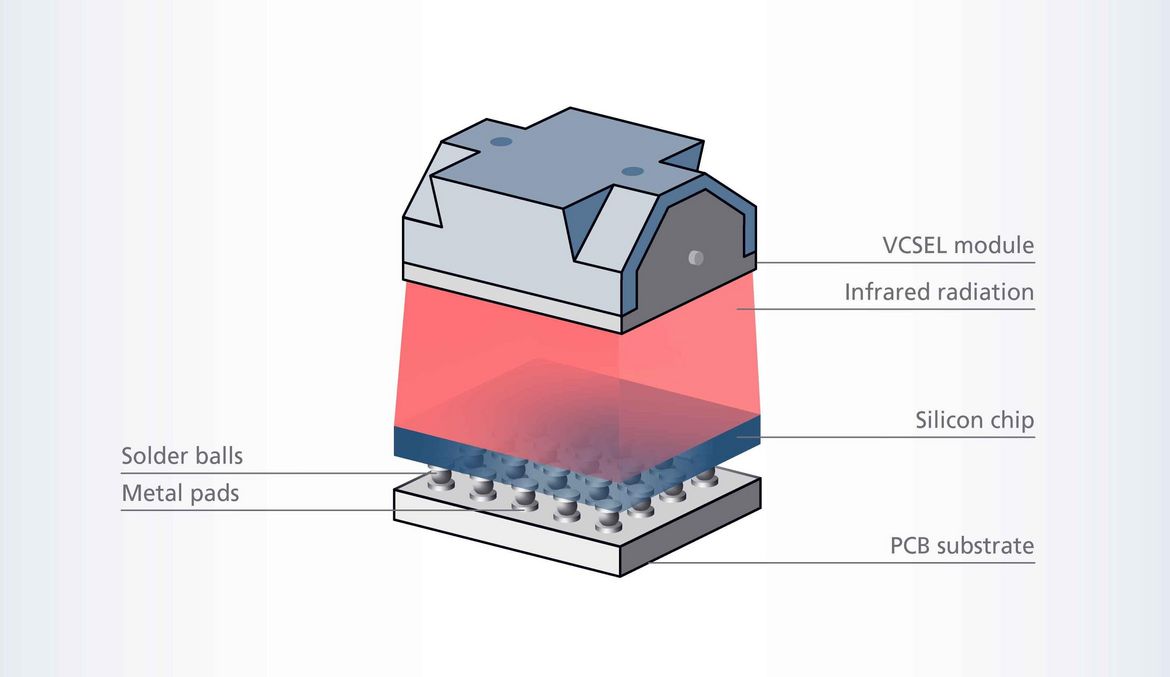

Beam sources based on VCSEL arrays are able to heat large surfaces with directed wavelength-selective infrared radiation. The TruHeat VCSEL systems are used in numerous industrial heating processes. Due to direct irradiation of the treatment surface, significant cost benefits can be achieved compared to conventional laser systems, without expensive optics or scanner systems. The unique thing about the systems is that, in addition to the precise control and fast switch-over of the infrared output, the spatial heating profile can also be programmed as needed through independent control of small segments of the laser modules. The heating patterns can even change dynamically during operation. This enables unparalleled process flexibility.

Benefit from a scalable output power in the kW range.

Achieve a high process speed with irradiance of 100 W/cm².

Individual emission zones of the VCSEL beam source can be controlled independently of one another.

The robust and compact laser modules can be integrated easily into industrial systems and production processes.

TruHeat VCSEL Series 3000

The standard modules of the TruHeat VCSEL Series 3000 are available in 2.4 kW, 4.8 kW, 9.6 kW and 19.2 kW versions. The standard modules are used for directional, large-area heating applications. The beam is directed straight at the respective application area without the additional use of optics or a scanner system.

TruHeat VCSEL 3012

The TruHeat VCSEL 3012 system has a relatively low irradiance with a large width. This is why it is especially suitable for drying battery foils. Several modules can be arranged one after the other to create a longer drying path.

Specialized solutions

The VCSEL heating systems are flexible and can be easily adapted to customized requirements. Depending on the customer application, the correct configuration of VCSEL heating system is determined together with the customer.

The image shows a compact laser module with 32 VCSEL arrays and focusing optics for use in the 3D printing of plastics or the marking of packaging material. Each VCSEL array can be controlled individually, with an output power of 2 W.

Control software for TruHeat VCSEL systems

Basic Driver Control Software

The basic version of the control software offers the function of manually controlling the laser channels of the TruHeat VCSEL system and of setting the power.

Advanced Driver Control Software

The extended control software version is based on the basic version and offers additional functions such as temperature control or pulsing. In addition, time and performance profiles can be created. These can be used to vary the power of the TruHeat VCSEL system during the processing time.

The heat density of TruHeat VCSEL systems can be influenced with additional lenses. The irradiance of VCSEL heating modules can be increased with positive lenses. The use of negative lenses decreases the irradiance of the modules.

The Air Knife can be used to keep spatter and steam away from the protective glass of the laser system. It creates a protective airflow in front of the laser.

Mounting brackets simplify the technical assembly of a TruHeat VCSEL system.

A TruHeat VCSEL system with less tightly packed emitters and a defocusing lens can be used for applications requiring less irradiance.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.