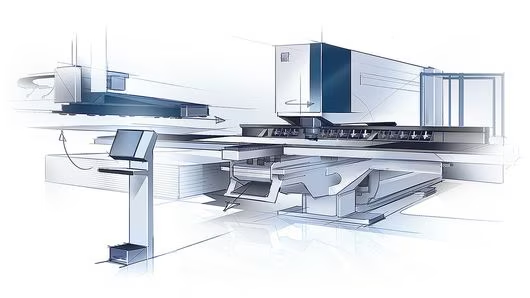

Cost-effective entry-level machine

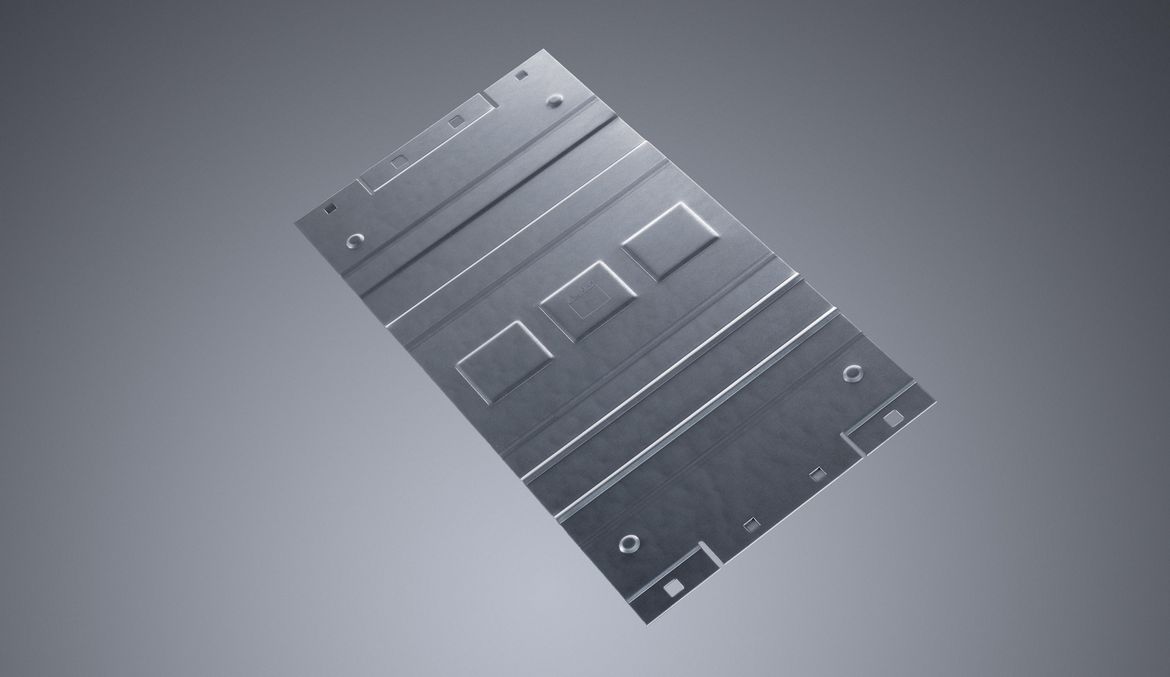

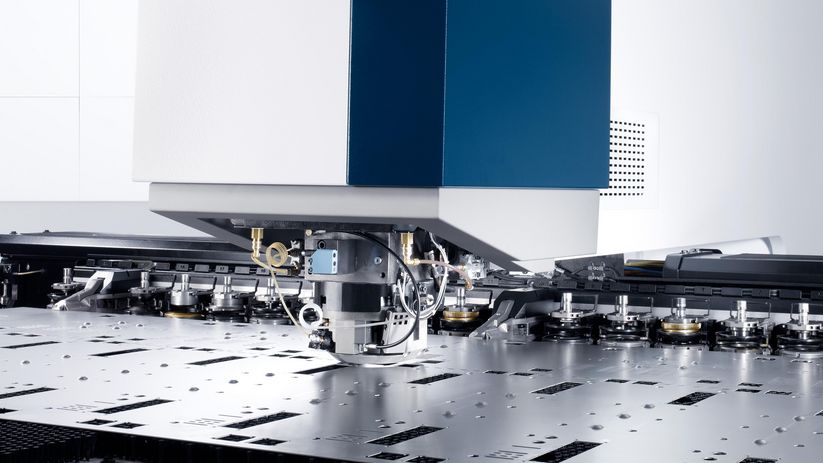

The TruPunch 1000 is the perfect entry to professional punching. The compact machine excels with its high level of processing flexibility: In addition to just punching, you can also use it to form threads, extrude, and bend flanges. You can process midsize sheets completely in one tool setup without repositioning. You can even produce smaller orders and lot sizes economically, quickly and with flexibility.

The TruPunch 1000 masters all of the relevant applications of a TRUMPF punching machine.

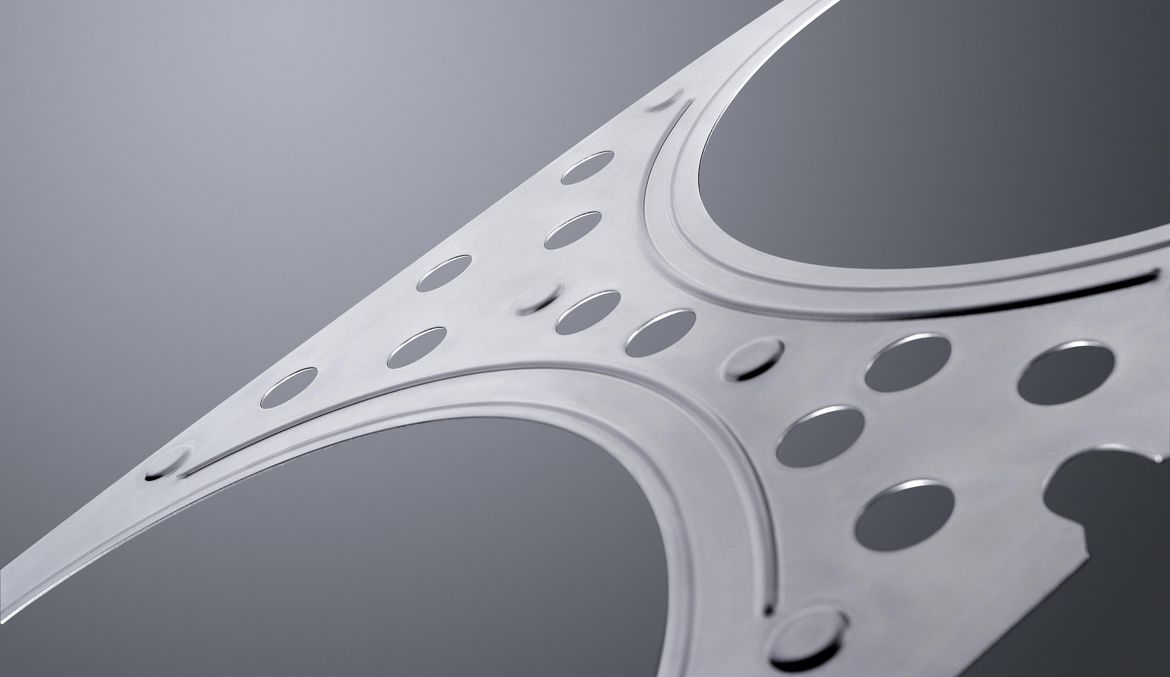

TRUMPF offers top quality punching tools such as the MultiTool or the MultiShear slitting tool.

The intuitive control enables the immediate production of simple and complex parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- The dimensions are approximate; the dimensions specified in the installation plan are valid.