Processing tubes - faster than ever before

The TruLaser Tube 5000 fiber takes advantage of the strengths of solid-state lasers in a way that no other machine ever has before. For you as a user, this means short processing times for a large range of possible tubes and profiles. The latest version of the machine is even more convincing: it is more efficient, processes even heavier tubes and cuts through thicker materials thanks to increased laser power. See for yourself!

With RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours.

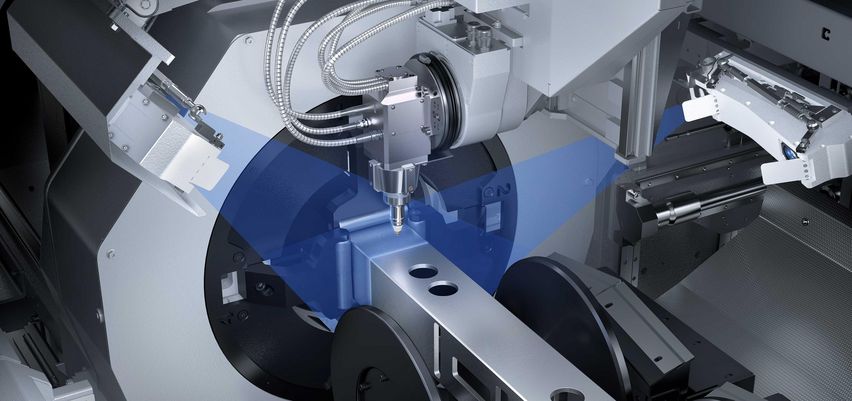

Thanks to its open concept, the TruLaser Tube 5000 fiber offers optimum access.

With the clamping system of the TruLaser Tube 5000 fiber, tubes can be manufactured across the entire clamping range without the need for retooling.

Solid-state lasers and cutting data from TRUMPF - perfectly matched for the best cutting results.

The bevel cutting option enables high-quality bevel cuts of up to 45°.

The state-of-the-art sensor system ensures your entire machining process runs smoothly.

Cut out another work step: The TruLaser Tube 5000 fiber taps threads.

The outer circle extension provides more clearance during processing for round and rectangular tubes.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Round tubes with a diameter of 152 mm to 170 mm can only be manually loaded.

- Rectangular profiles with a side length of >152.4 mm can only be manually loaded

- Value for extended versions (option)