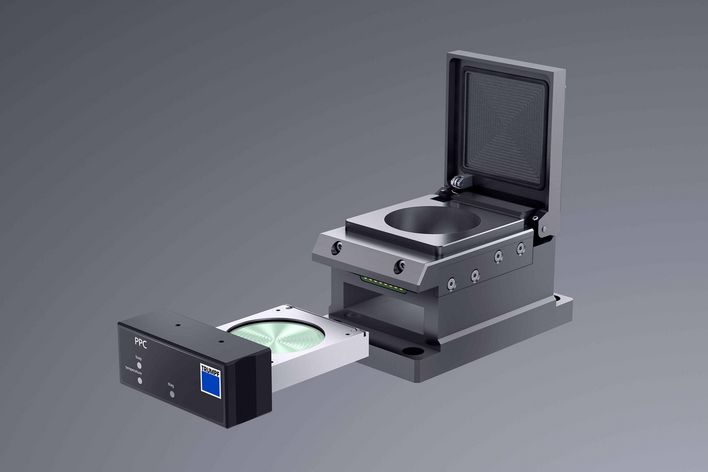

Simple and reliable calibration

The CalibrationLine from TRUMPF checks whether the focal position and laser power on the workpiece actually match your requirements, at regular, individually definable intervals. If necessary, the calibration tool corrects the focus in the X, Y, and Z direction, as well as the laser power, and brings the program back in line with reality using TruControl, control software. This ensures a high degree of repetition accuracy. The data recorded by the CalibrationLine is stored in a FIFO database so that as the user, you can access detailed measuring data at any time. You can also export the data into your databases if necessary. Some data are also available via Quality Data Storage.

CalibrationLine calibrates and evens out focal position and temperature drift.

Optimum welding results, even after replacing the fiber optic cable or focusing optics.

Guaranteed traceability due to stored, detailed measured values.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.