|

Laser parameters

|

|

|

|

|

|

Wavelength

|

-

|

-

|

-

|

-

|

|

Power

|

up to 6000 W (cw)

|

up to 12000 W (cw)

|

up to 8000 W (cw)

|

PFO SF20: to 8000 W (cw)

PFO SF33: to 12000 W (cw)

|

|

Numerical aperture

|

typ. 0.11 / max. 0.12

|

typ. 0.11 / max. 0.12

|

typ. 0.11 / max. 0.12

|

typ. 0.11 / max. 0.12

|

|

Laser light cable type

|

LLK-D

|

LLK-D

|

LLK-D

|

LLK-D

|

|

Optics configuration

|

|

|

|

|

|

Collimation

|

90 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode, TruFiber BrightLine Mode)

100 / 175 mm (TruFiber Single Mode)

|

140 mm (TruDisk, TruFiber Multi Mode, TruFiber BrightLine Mode, TruMicro 7000)

175 mm (TruMicro 7000)

150 / 200 / 300 mm (TruFiber Single Mode)

|

138 mm

|

PFO SF33: 140 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode, TruFiber BrightLine Mode)

PFO SF33: 300 mm (TruFiber Single Mode)

|

|

Focal length

|

100 / 135 / 160 / 264 / 315 / 400 mm

|

255 / 345 / 450 mm (Standard)

160 / 265 / 345 / 450 / 550 / 700 mm (High Brightness)

|

255 / 345 / 450 / 600 / 900 mm

|

200 / 250 / 300 / 400 / 500 / 600 mm

|

|

Z stroke for focal length of lens

|

-

|

-

|

f345: ± 40 mm

f450: ± 70 mm

f600: ± 100 mm

f900: ± 220 mm

|

-

|

|

Field size (ellipse Y x X) for focal length of lens

|

-

|

-

|

f255: 174 mm x 102 mm (z=0)

f345: 240 mm x 140 mm (z=0)

f450: 320 mm x 190 mm (z=0)

f900: 525 mm x 340 mm (z=0)

|

f200: 11 mm x 17 mm

f250: 14 mm x 21 mm

f300: 17 mm x 25 mm

f400: 22 mm x 34 mm

f500: 28 mm x 42 mm

f600: 28 mm x 42 mm

|

|

Field size (ellipse Y x X) for lens focal length for TruDisk, TruMicro 7000, TruFiber Multi Mode ≥ 100 µm

|

-

|

f255: 180 mm x 112 mm

f345: 244 mm x 150 mm

f450: 320 mm x 196 mm

|

-

|

|

|

Field size (ellipse Y x X) for lens focal length for TruDisk, TruMicro 7000, TruFiber Multi Mode/Single Mode/BrightLine Mode High Brightness objective

|

-

|

f160 HB: 80 mm x 57 mm

f265 HB: 140 mm x 102 mm

f345 HB: 208 mm x 152 mm

f450 HB: 306 mm x 208 mm

f550 HB: 388 mm x 257 mm

f700 HB: 570 mm x 370 mm

|

-

|

|

|

Field size (ellipse Y x X) for focal length of lens for TruFiber/TruDisk IR/TruMicro 7000

|

f100: 51 mm x 37 mm

f135: 78 mm x 57 mm

f160: 92 mm x 71 mm

f264: 180 mm x 148 mm

f315: 250 mm x 188 mm

f400: 320 mm x 237 mm

|

-

|

-

|

|

|

Field size (ellipse Y x X) for focal length of lens for TruDisk 515 Nm

|

f100: 49 mm x 36 mm

f135: 75 mm x 54 mm

f160: 89 mm x 68 mm

f264: 180 mm x 144 mm

|

f160 HB: 77 mm x 57 mm

f255: 172 mm x 108 mm

f265 HB: 140 mm x 102 mm

f345: 234 mm x 145 mm

f345 HB: 202 mm x 144 mm

f450: 312 mm x 190 mm

|

-

|

-

|

|

Structural design

|

|

|

|

|

|

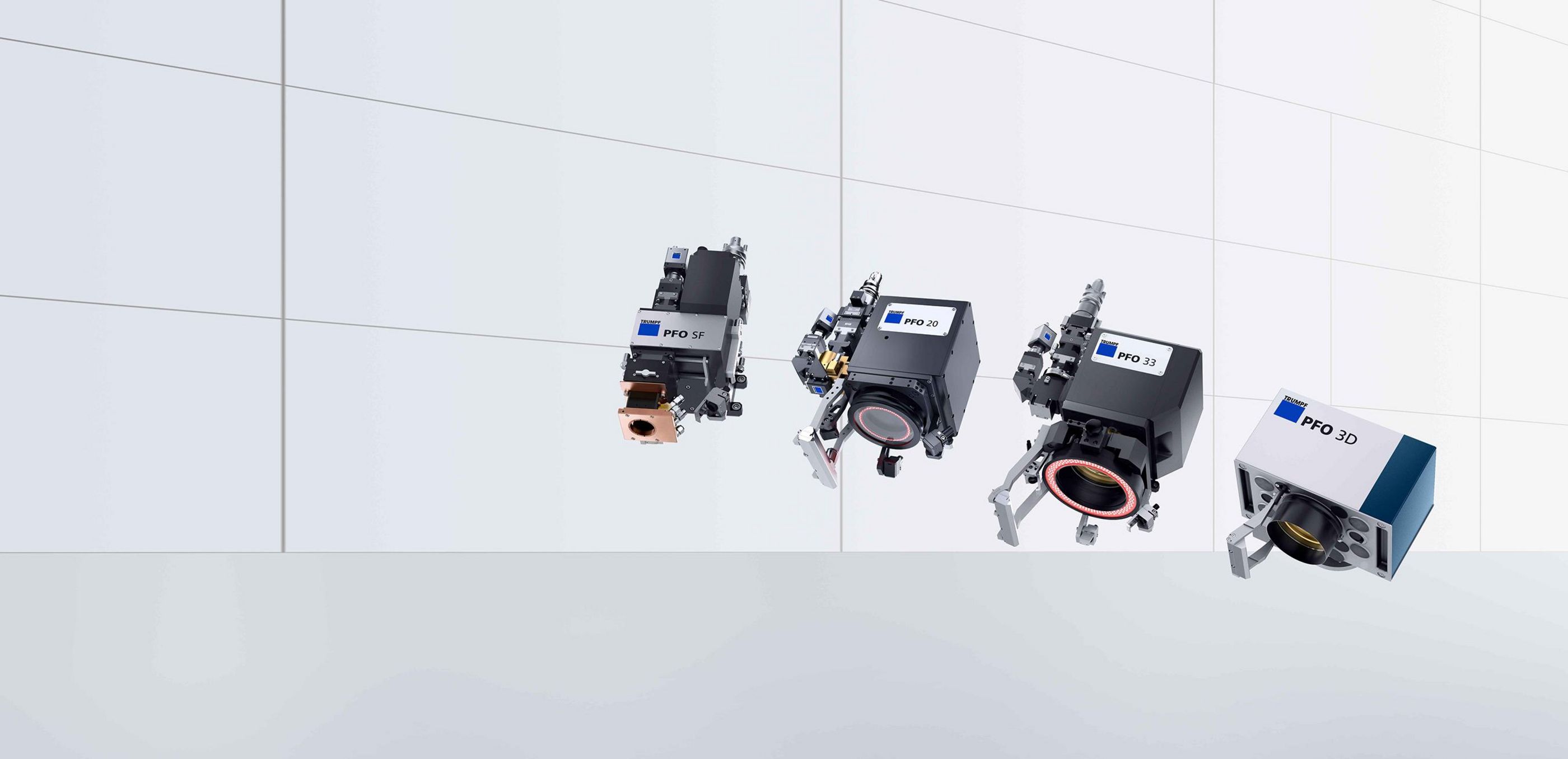

Dimensions (W x H x D)

|

227 mm x 202 mm x 197 mm (configuration example with fc90 and f264)

|

336 mm x 340 mm x 227 mm (configuration example with fc140 and f450)

|

412 mm x 266 mm x 366 mm

|

223 mm x 200 mm x 198 mm (Scanner head without objective lens)

120 mm x 195 mm x 252 mm (PFO control unit)

|

|

Weight

|

Approximately 30 kg

|

< 35 kg

< 38 kg with OCT scanner

|

35 kg

|

13 kg (Scanner head)

4 kg (PFO control unit)

|

|

Compatibility

|

|

|

|

|

|

Available lasers

|

TruDisk, TruFiber multiple mode and single mode, TruMicro 7000

|

TruDisk, TruFiber, TruMicro

|

TruDisk

|

PFO SF 20: TruDisk, TruMicro 7000, TruFiber multiple mode, TruFiber single mode

PFO SF 33: TruDisk, TruMicro 7000, TruFiber multimode, TruFiber single mode, TruFiber BrightLine Mode

|

|

Available sensor system

|

VisionLine Cam/Basic/Detect/Project, CalibrationLine Power/Focus

|

VisionLine Cam/Basic/Detect, VisionLine OCT Detect/Check, CalibrationLine

|

VisionLine, CalibrationLine, SeamLine Remote, OCT seam position control

|

VisionLine Cam/Basic/Detect, CalibrationLine

|

|

Options

|

|

|

|

|

|

Available options

|

Crossjet, MVE nozzle, camera monitoring, sensor interface, lighting, smoke bell, beam shaping for green lasers, Simple Coordination PFO (SCP) with encoder

|

Crossjet, dual Crossjet, MVE nozzle, smoke bell, camera monitoring, sensor interface, lighting, protective glass monitoring unit, Simple Coordination PFO (SCP) with encoder, multifocus element, beam shaping for green lasers

|

I-PFO, crossjet, MVE nozzle, smoke bell, lighting version

|

Crossjet, MVE nozzle, various shielding gas nozzles, camera monitoring, sensor interface, lighting, protective glass contamination monitoring, coolant monitor, adjustable line laser

|

|

Available software options

|

TruTops PFO, PFO Smart Teach App, Real-time Contour Check (RCC)

|

TruTops PFO, PFO Smart Teach App, Real-time Contour Check (RCC)

|

TruTops I-PFO and TruTops PFO, PFO Smart Teach App

|

TruTops PFO, PFO Smart Teach App, Real-time Contour Check (RCC)

|