Challenges

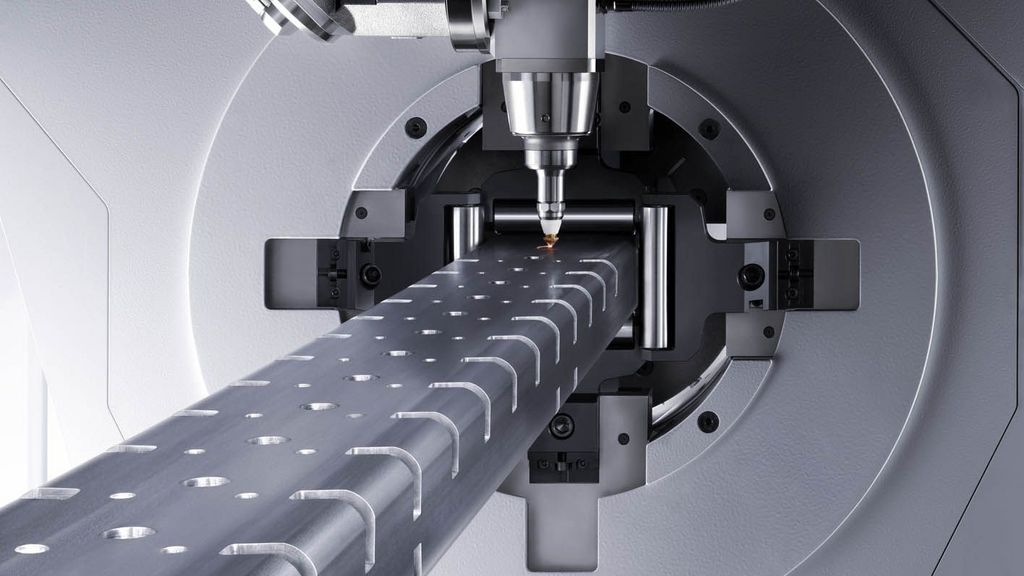

JKE has grown rapidly since it was founded. The contract manufacturer produces components for lawn mowers, industrial sewing machines, fire engines or lifts, for example. 65 percent are exported into the USA, to Europe and Australia. Wu explains their business success: "Our ambition from the very beginning was to be one of the best. So, right from the start, we decided we would only work with the best in the field." This is why the couple are tackling a new market: highly complex tube designs for their native mechanical engineering industry. The venture was only possible with a carefully thought out investment beforehand.