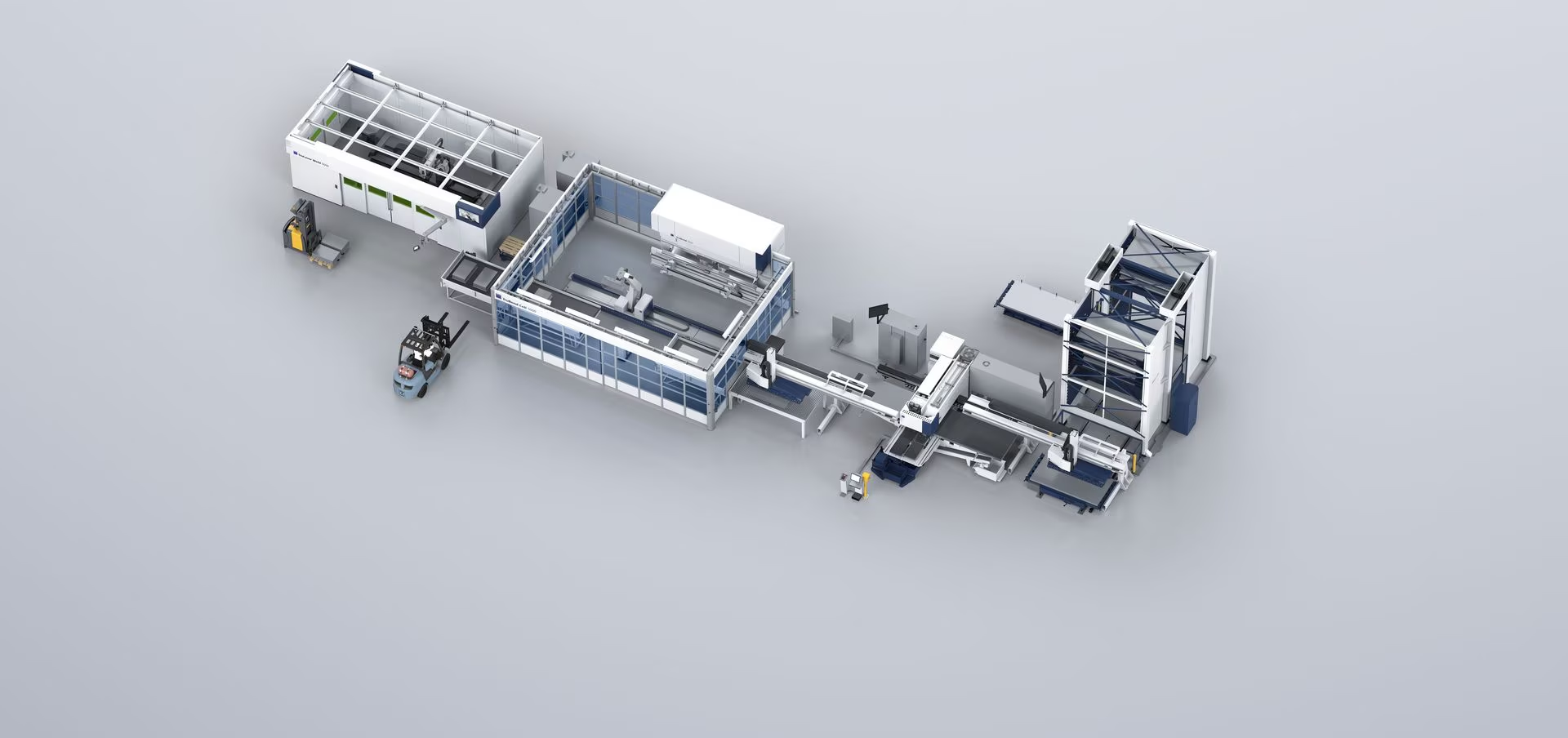

The TRUMPF Customer Center

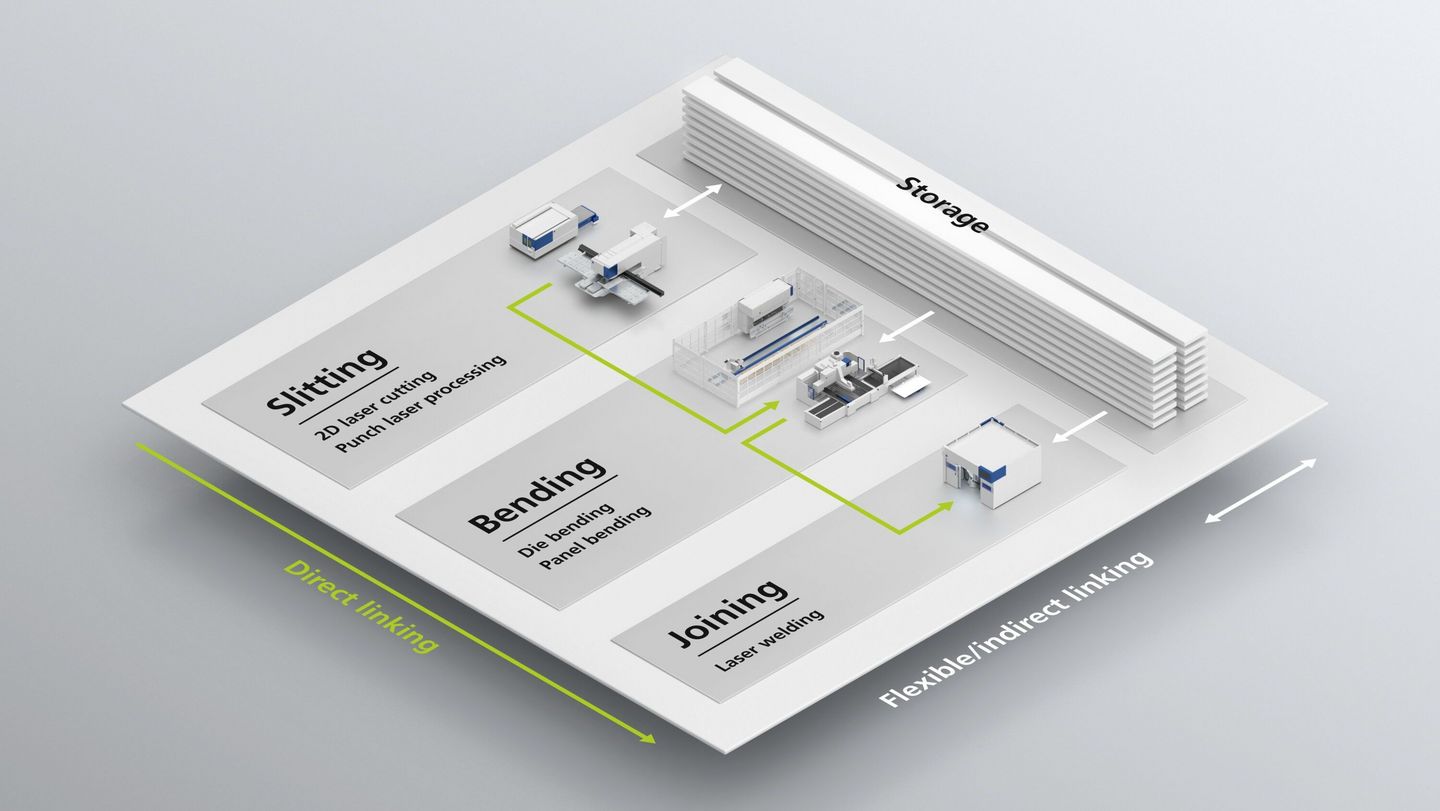

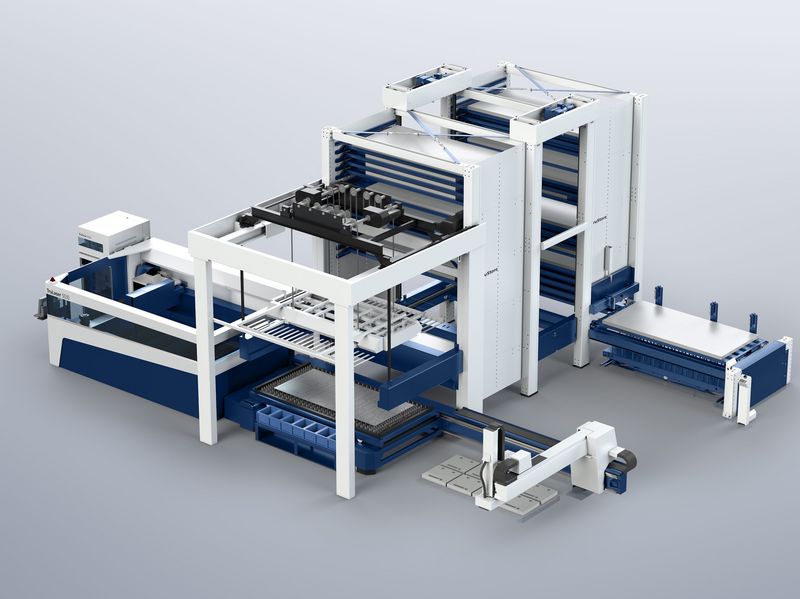

We ensure TRUMPF products are a comprehensive experience for our customers. The entire sheet metal process chain – from programming to laser welding – is represented in our most up-to-date product portfolio which is shown in our Customer Center, opened in 1987 and expanded in 2020.

You can have machines from different technologies demonstrated to you here. We offer standard product demonstrations as well as customer parts presentations Generation of time studies, feasibility checks and creation of sample parts are also some of the core tasks of the Customer Center.