Surgical instrument with unique device identification (UDI) marking

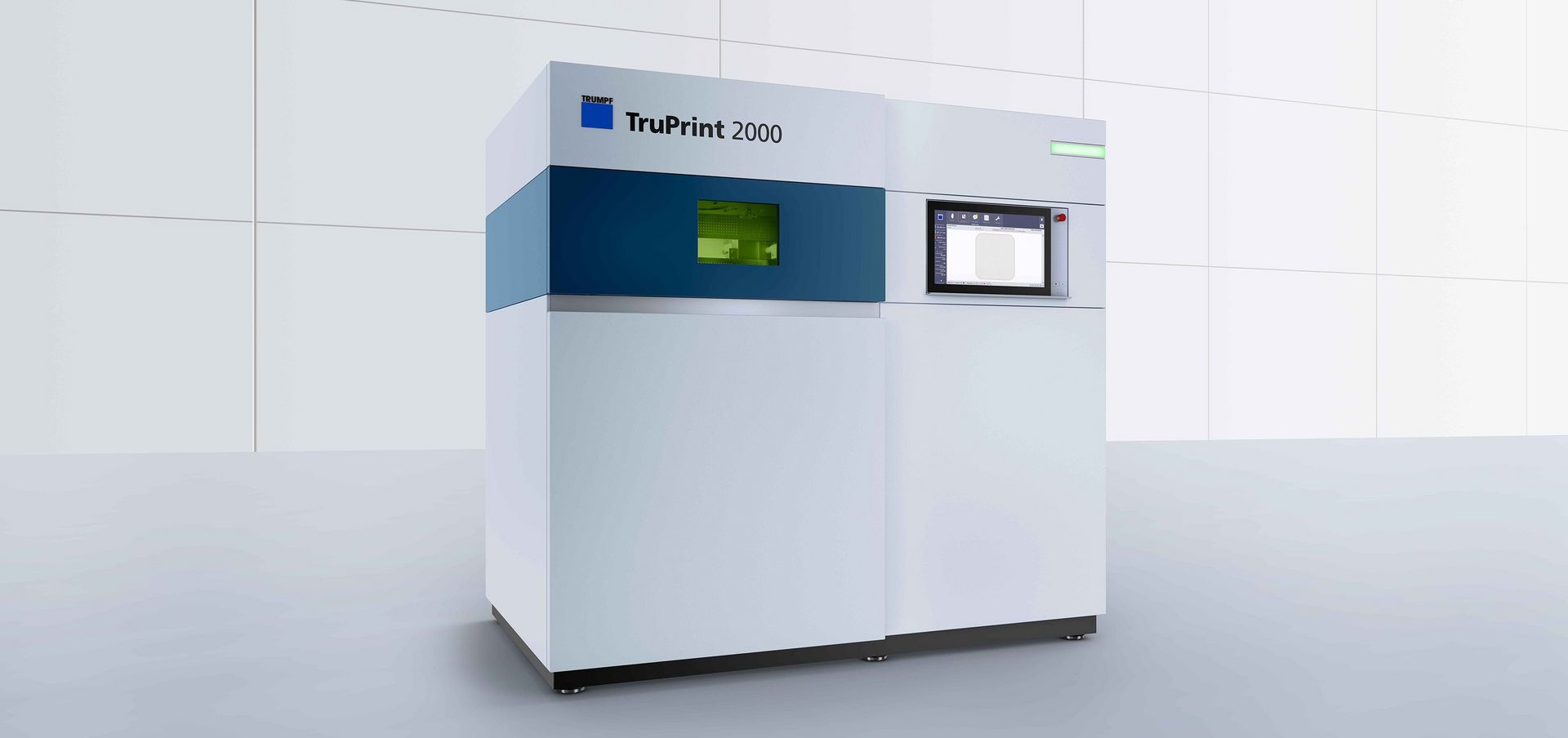

TRUMPF solutions can be successfully combined in medical technology. One example is the surgical forceps shown here, which are 3D printed and given a UDI marking. The Swiss m4m Center, which specializes in 3D printing, helps companies to integrate additive manufacturing solutions from concept design to pilot production. The company uses the TruPrint 2000 to produce stainless steel parts in a qualified production environment. The 300-watt fibre laser with a beam diameter of 55 macrometers guarantees outstanding printing results and surface quality for complex, intricate parts.

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures about the example part

Material: 17 – 4PH

Created by: Swiss m4m Center