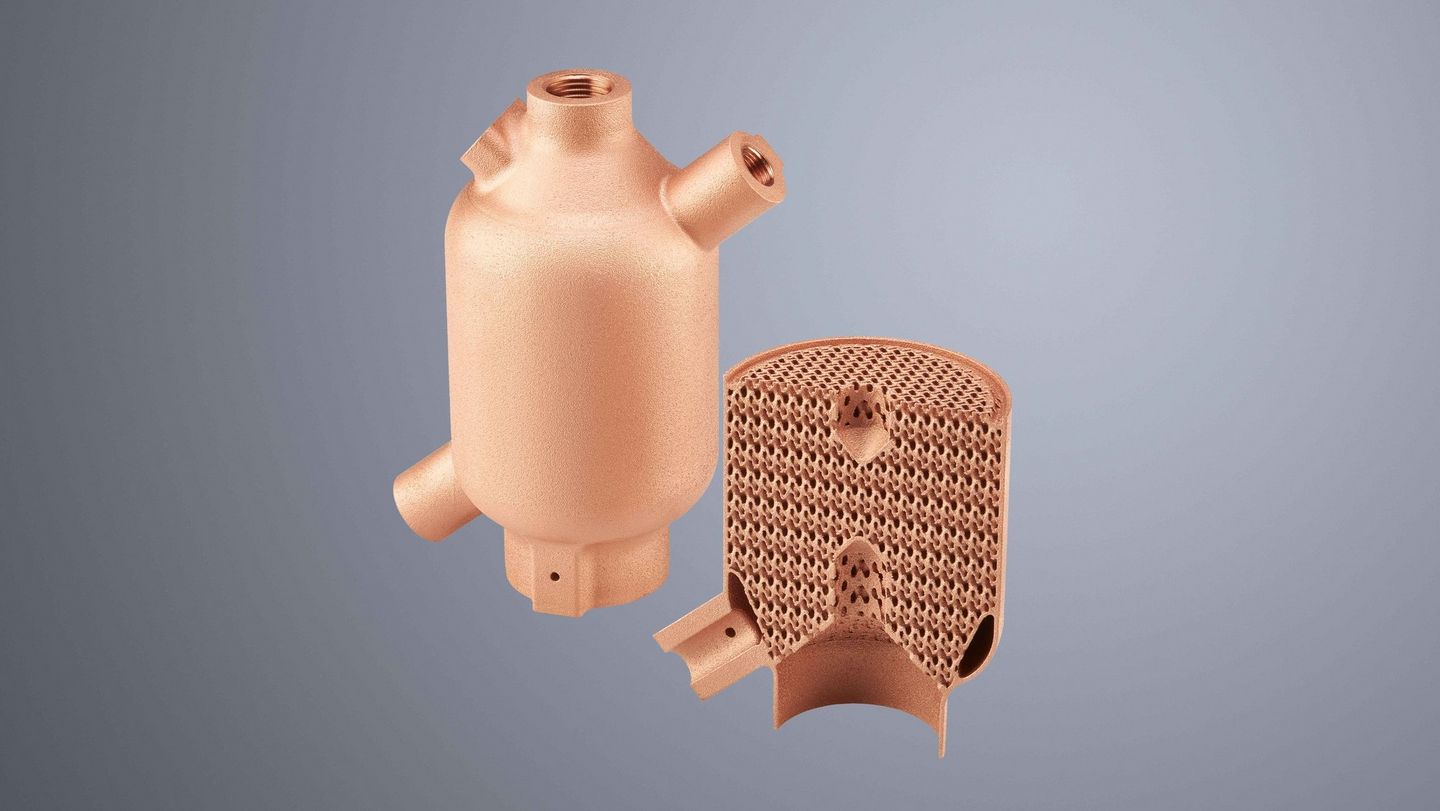

Gas cooler with TPMS structures

Heat exchangers are often single parts that are designed to meet the requirements for heat transfer and ambient conditions. This gas cooler, designed by Modell- und Formenbau Blasius GERG GmbH, uses additive manufacturing options in combination with a planar design of triple periodic minimal structures (TPMS) to increase the efficiency. It is used in a wood-fired power plant to cool down the exhaust gases by exchanging heat with water and recovering and reusing the heat. The design combined with a high-performance material such as copper results in excellent performance. This part is made from pure copper using the TruPrint 5000 Green Edition. This is equipped with a green laser to machine this highly reflective material with the right tool. The material properties are the same as conventional pure copper ETP without the need for heat treatment (101% IACS conductivity, 394 W/(m*K) thermal conductivity).

TPMS structures increase the efficiency of the heat transfer

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures for an example part

Material: pure copper

Created by: Blasius GERG GmbH