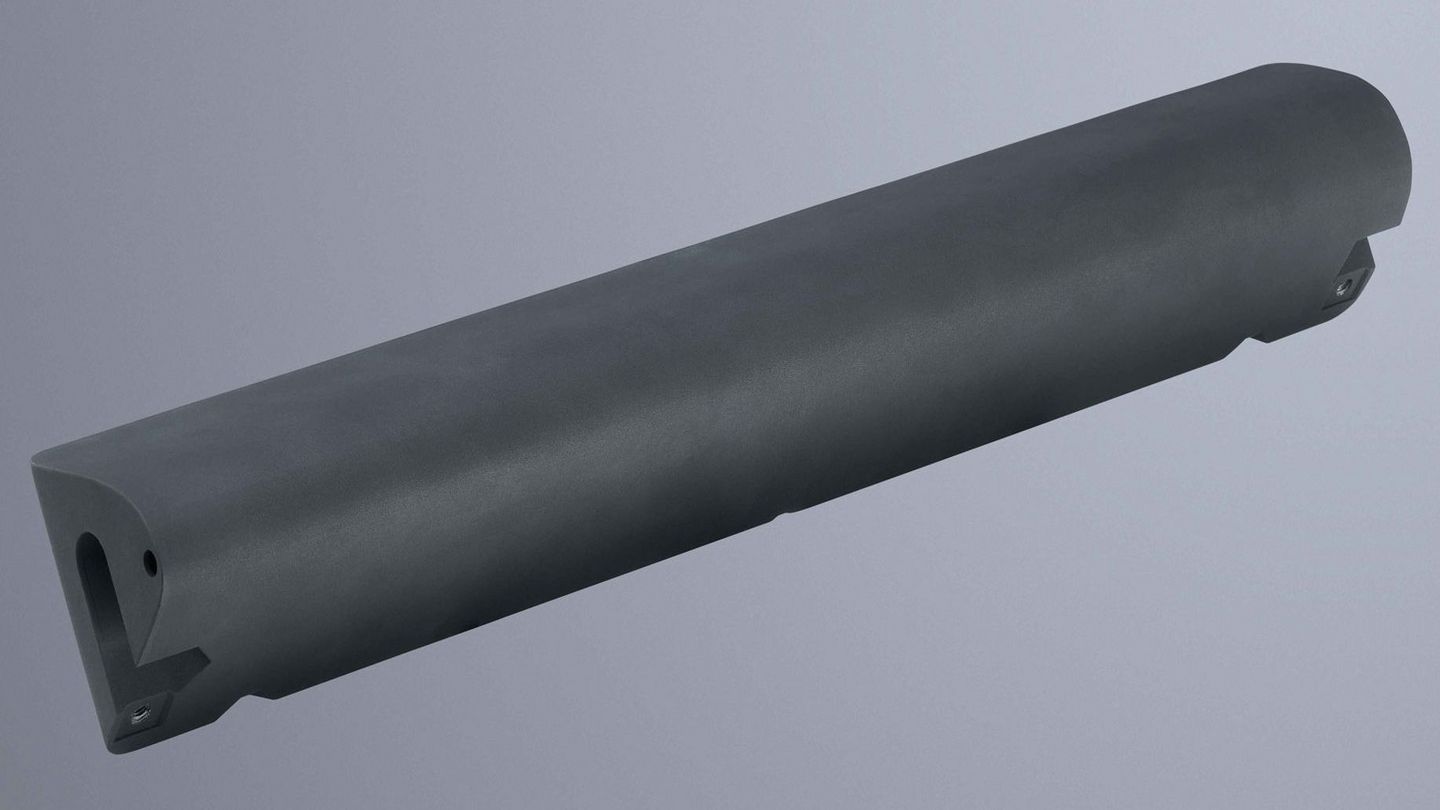

Air flow parabola

The suction parabola in the TruPrint 5000 allows the shielding gas flow to be recirculated evenly from the construction chamber. The component is hard anodised black for reasons of scattered beam reflection and corrosion resistance. Additive manufacturing allows the production of complex geometries at lower component costs compared to conventional manufacturing methods.

Get in touch with our additive manufacturing experts!

Do you have a component that you would like to 3D print? Would you like to know what potential savings there are, and what advantages you could benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Facts & figures about the example part

Material: AlSi10Mg

Volume: 172 cm³

Components: 1

Height: 400 mm (fitted)

Weight: 460 g

Construction time: 70 hours for 18 items

Number of layers: 6701

Created by: TRUMPF