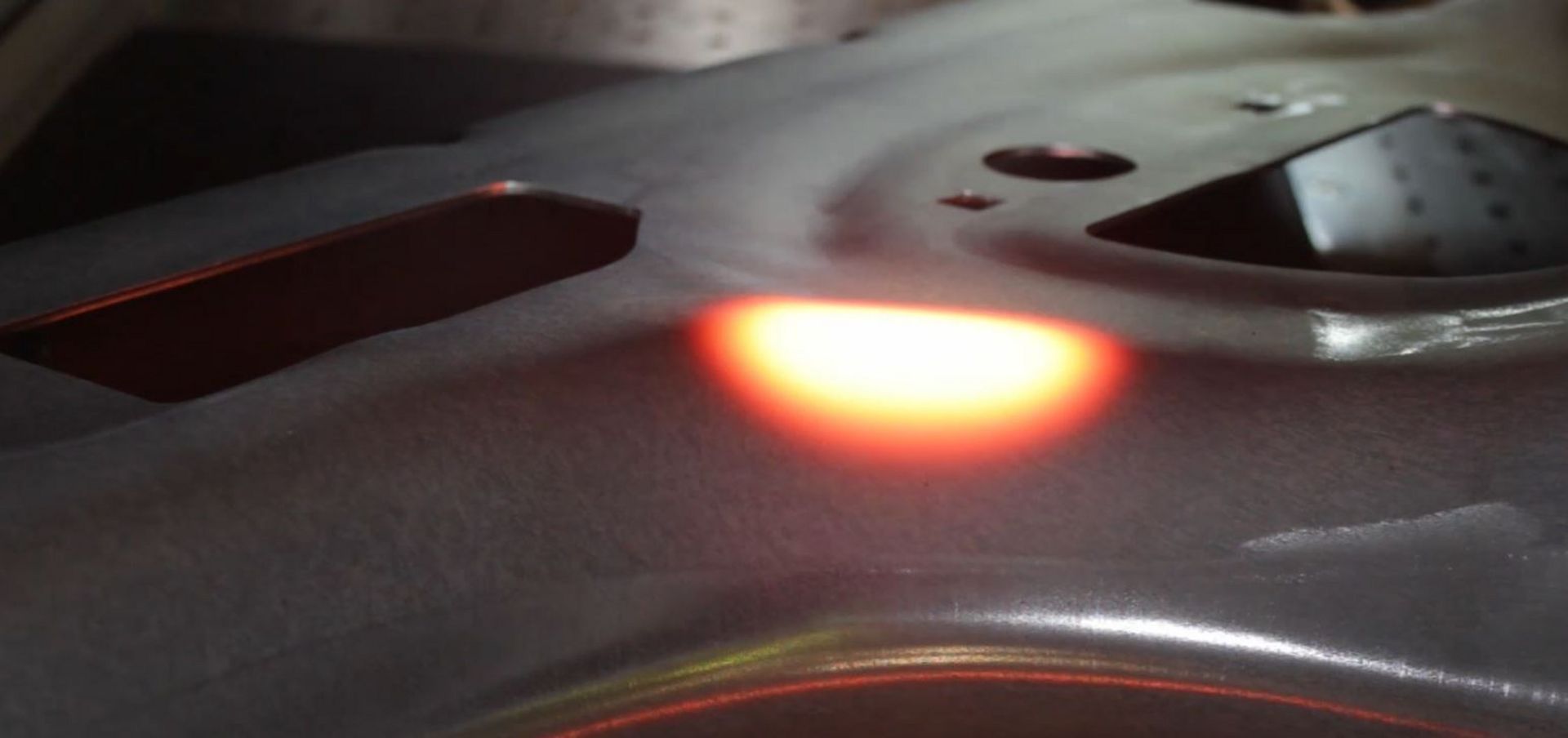

VCSEL lasers are used as a tool for surface heating in many industrial processes. As a high-intensity infrared heat source, precisely directed diode laser heat treatment with selective wavelength radiation is both scalable as well as energy-efficient. VCSEL laser arrays assist with drying and sealing. In principle, they are designed to be optimal for all processes in which precise surface and temperature controlare crucial. In addition, VCSEL heating systems use IR cameras or pyrometers to support temperature measurement during heat treatment. Laser heat treatment modules are very well-suited for flexible large-area heating applications requiring high precision. Compared to conventional heating methods, users benefit from significantly more flexibility, precision and cost savings.

VCSEL laser heat treatment for drying and sealing

Contact