Annealing: using the laser to apply long-lasting markings to metal

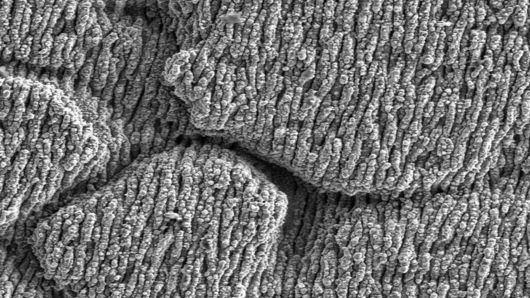

Annealing is an established method for applying long-lasting markings to steel and metals. This is due to the fact that these materials show annealing colours when heated with a laser. These colours are highly dependent on the temperature at which the metal is heated. This is caused by an oxide film being generated on the surface during annealing; the oxide properties determine the colour impression.

The main advantage of annealing: the surface remains completely intact; the marking is easily legible, long-lasting and resistant to abrasion. Annealing is ideal wherever a precision fit must be maintained or material bulging is prohibited. This is why this procedure is ideal for consumer goods such as cooking utensils or medical products, for example.

How annealing works: the procedure for laser marking of metals

In order to generate annealing, the laser heats the metal locally until just before its melting point. During this process, the structure of the lattice changes; oxide is generated on the workpiece surface which is shown by the appearance of different annealing colours. These colours are temperature-stable up to approximately 200 °C. If temperatures are higher, the lattice reverts to its normal state – the mark disappears. The surface finish remains completely preserved.

In general, annealing is only possible with metals which change colour under the influence of heat and oxygen, i.e. steels and titanium, but not with aluminium or non-ferrous metals. It is also not possible to mark hard metals with a dark contrast using the annealing procedure.

What are the advantages of annealing with a laser?

The material surface is hardly affected by the marking process and remains smooth even after the mark has been applied.

Due to the smooth surface, hardly any organic residue can stick to the annealing. It is therefore particularly suitable for objects which are often cleaned.

With the right selection of parameters, annealing markings remain intact and legible - even after numerous cleaning cycles, as is common with many medical products.

Annealing has become established in medical technology in recent years and, along with the innovative black marking procedure using ultrashort pulse lasers, is ideal for product identification for unambiguous traceability, also in line with UDI guidelines.