Amorphous metals are also called metallic glasses and are quite unusual all-round talents. For even though extremely strong, they are also highly elastic at the same time. Two actually opposing characteristics, the unique nature of metallic glasses makes this possible. Compared to crystalline materials, amorphous metals do not have an ordered lattice structure. This is created by the melt's high cooling rate. This prevents an even distribution of the atoms. The result: an amorphous, in other words, non-crystalline solid body where the atoms remain in an almost disordered state.

3D printing amorphous metals

Extremely strong and yet highly elastic: amorphous metals, also called metallic glasses, are THE new super material in 3D printing for numerous high-tech applications. Its fascinating properties have enormous potential for innovative components in the medical technology, aerospace, robotics, e-mobility or lifestyle sectors.*

What are amorphous metals?

What are the benefits of metallic glasses?

A high level of hardness and strength with concurrent extreme elasticity: this unique combination yields countless benefits in the production of amorphous components.

Amorphous components have the same material properties in all directions. This offers many advantages, for example, in additive manufacturing. The build volume can be utilised in the best possible way in combination with the component's orientation.

3D-printed amorphous components are biocompatible, making them predestined for many medical technical applications. Amorphous implants can be customised to fit the patient's body shape.

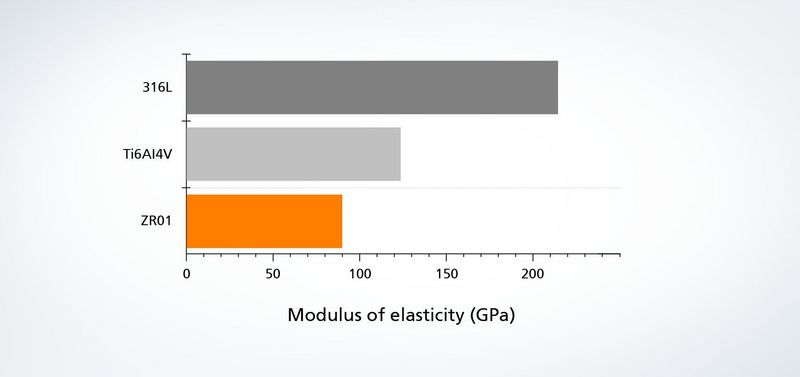

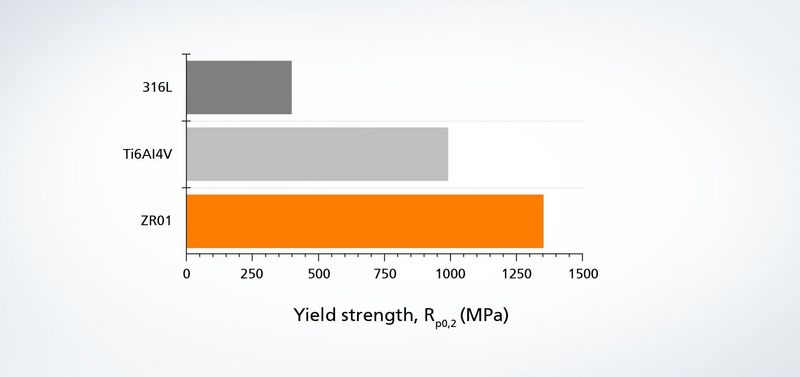

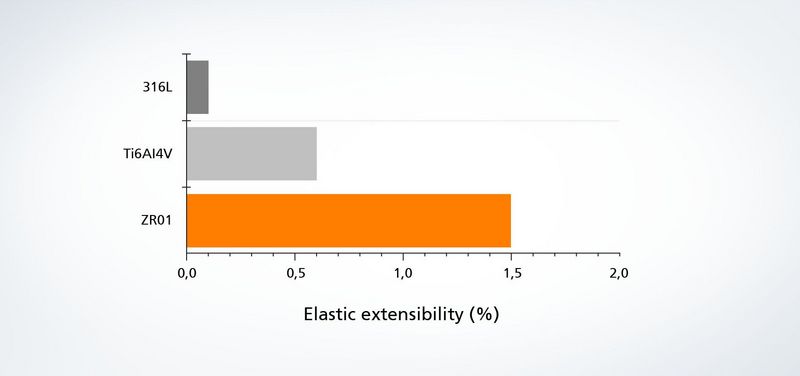

Amorphous metals have a high yield strength combined with an elastic elongation of almost 2%. This provides many benefits in the production of implants, sensors or flexure joints as absorption is significantly improved.

Thanks to the high level of strength, it is possible to make amorphous metallic components thinner, saving more material, and making them lighter. This is particularly important in the robotics or medical technology sectors, as well as in aerospace and e-mobility.

Amorphous metals have low temperature ductility, which means that they are excellent for use in applications with extremely low temperatures and they retain their properties. This makes this material class perfect for the aerospace sector.

Amorphous metals have a very high level of hardness and therefore little abrasion, comparable with ceramic. This property is particularly important for heavily stressed components in tool and mould making as well as for lifestyle products such as high-quality watches.

Amorphous metals – 3 questions about the new super material

Together, TRUMPF and Heraeus AMLOY have developed a procedure which works with a very fine focus and extremely small melt volume. The heat dissipates quickly. This equates to the critical cooling time of 200 kelvin per second: a customised and amorphously solidified implant rises out of the powder bed.

Since metallic glasses do not have lattice structures, they behave completely differently to other metals. They are simultaneously extremely strong, highly elastic and very wear-resistant. Implants made of amorphous metals can withstand the enormous stresses and strains in the human body very well. This does not only include knocks or jolts. Biting and chewing regularly subjects the jawbone to constant stress; a rib cage has to withstand around eight million breaths per year.

Amorphous alloys have an elasticity module which is similar to that of human bones. This provides enormous benefits for the healing process and the resilience of the previously weak point in the body. At the same time, alloys are resistant to corrosion and certified in terms of biocompatibility.

Amorphous metal alloys – a look at four characteristics

Heraeus AMLOY has developed ground-breaking alloys which are exceptionally suitable for the production of innovative implants, among other things. Zirconium-based alloys such as Amloy-ZR01 and Amloy-ZR02 are available even now. The latter is already a certified material in terms of biocompatibility in accordance with ISO 10993-5 and ISO 10993-12. Furthermore, titanium is considered a material for medical components such as bone implants or pacemakers. The current research into titanium alloys for applications in medical technology is very promising. Whether titanium or zirconium – amorphous alloys impress with different properties and are therefore particularly suitable for specific applications.

White paper

From a lifestyle watch to medical technology to lightweight design: amorphous metals open up new application options for a multitude of sectors and industries. One of the main great advantages is the combination of 3D printing and metallic glasses. Find out all about it!

Which amorphous applications are available?

From a lifestyle watch to medical technology to lightweight design: amorphous metals open up new application options for many sectors and industries. Thanks to the combination of 3D printing and metallic glasses, one thing is for certain: the material can be optimally processed, generating the finest structures with smooth surfaces. Applications requiring very high corrosion resistance and wear resistance can be ideally implemented.

Medical technology

Medical technology gets just what it wants with amorphous metals: the perfect material for the production of long-lasting scalpels or minimally invasive instruments. But even in the human body, amorphous metals will play an important role in future – as implants.

Lifestyle products

Polishable high-quality surfaces and scratch resistance give lifestyle products the "wow" factor. This makes them essential for high-grade entertainment electronics, watches and jewellery.

General industries

Thanks to the additive method, many industrially manufactured components can be produced "as a whole". This means that the components do not have to be manufactured individually and subsequently assembled.

Why 3D printing and amorphous metals are a real dream team: read here how the TruPrint systems from TRUMPF and the ultra-pure, specially optimised powders from Heraeus AMLOY work together perfectly.

These machines enable amorphous printing – even in series

A real dream team: 3D printing and amorphous metals. Or more precisely: the TruPrint systems from TRUMPF and the ultra-pure, specially optimised powders from Heraeus AMLOY. This is because the TruPrint 1000 and 2000 are particularly suited for printing amorphous metals. The small beam diameters generate the highest surface qualities. This simplifies the refinishing process of the applications or even renders them unnecessary. Excess powder can be prepared "inertly", that is, using shielding gas. This protects the material from harmful effects such as oxygen which is quick to react with metallic glasses. With a beam diameter of 55 µm, the laser generates a small weld pool. The heat dissipates quickly and the critical cooling time of 200 Kelvin per second can be maintained. This means that the metal cannot crystallise. In the TruPrint 2000, two 300-watt lasers scan the entire build volume in parallel. This means amorphous components can be manufactured productively in series, and to a high quality standard. Thanks to Condition Monitoring, Powder Bed Monitoring and Melt Pool Monitoring, errors in the process can be detected early on. A perfected process.

Ask the Expert: our material specialist Christian Schauer explains

White paper

Further information on amorphous metals can be found on: www.heraeus-amloy.com

*Header image source: Heraeus AMLOY