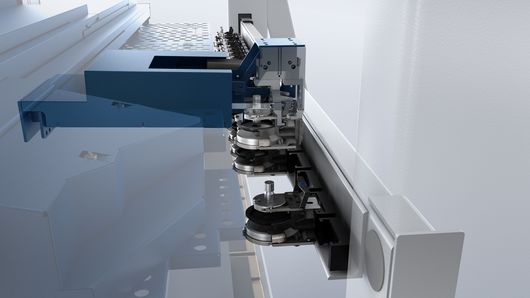

Minimise setup effort and maximise productivity: all punching heads at TRUMPF operate according to the mono punching head principle. This means that all punching tools can rotate by 360°. The benefits: all tools can be used in any angular position, they require significantly fewer punching tools than other designs.

The advantages of our punch laser machines

Punch laser processing is considered particularly lucrative – as the machines master two technologies at once: they combine the efficiency of punching and the flexibility of the laser. Furthermore, punch laser machines from TRUMPF, called TruMatic, provide particularly high-quality results and are as reliable as you want them to be.

1. Punching head

Punching in and of itself is a flexible technology, and the laser provides you with even more options. Punch laser machines from TRUMPF can laser cut, punch, form, tap, emboss, mark, engrave and deburr.

2. Lasers

As a metal-processing company, you know that the highest level of quality is often mandatory. You will achieve it with TRUMPF lasers. You can process all desired contours in the most varied of sheet thicknesses and materials. The results are outstanding.

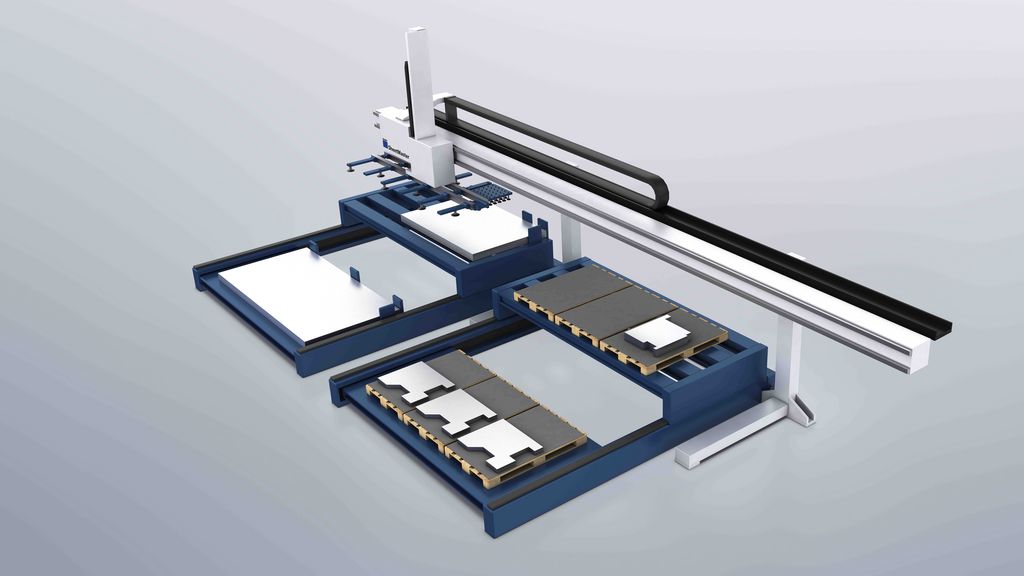

3. Material flow

Long waiting times are a thing of the past: your material flow becomes fluid with reliable automation processes.

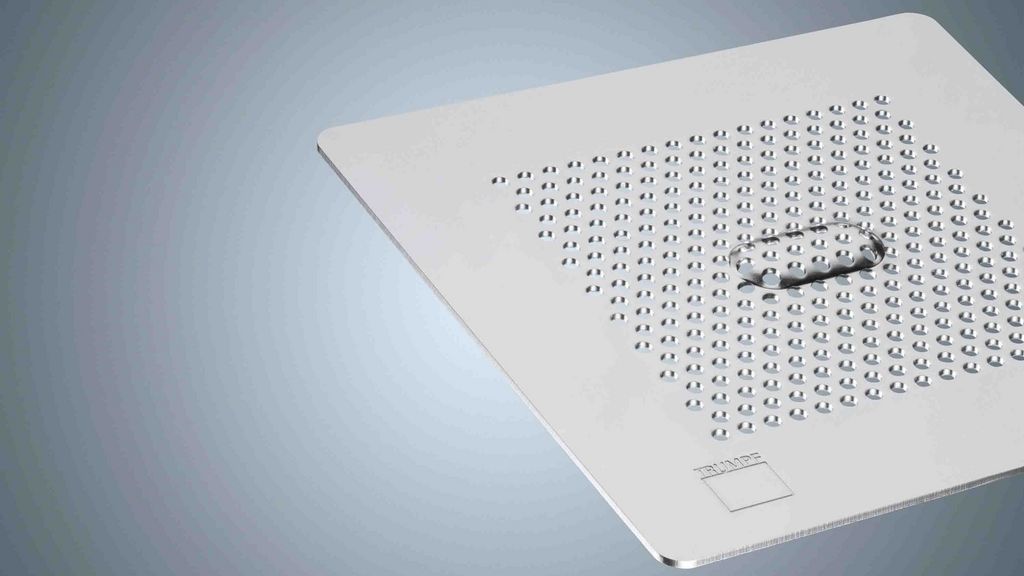

4. Quality

Thanks to your TruMatic machine, you will produce extremely high-quality parts requiring almost no reworking or even no reworking at all. This applies to punch or laser burrs as well

5. Process reliability

Make life easier for your operator and prevent extra work with clever functions.

1. Punching head – standard contours and forming with the punching head

2. Laser – Contouring freedom and optimum results using the laser

3. Material flow – logistical masterstroke

4. Quality – excellent part quality

TruMatic: your introduction to new sectors

State-of-the-art solutions from TRUMPF are being used in countless industries for a wide variety of tasks and applications: there are hardly any metal or tube components which cannot be manufactured productively and to the highest quality standards using a machine from TRUMPF's portfolio. Thanks to their flexibility, TruMatic machines are your opportunity to access new sectors – the automotive industry, for example.

An example: adjusting the inclination of a sport seat

Process steps of the TruMatic machine

Versatile and productive: punch laser machines from TRUMPF will take you further

Whether you want to produce your current parts more effectively and quickly or are supplying new customer groups – a punch laser machine from TRUMPF could be the perfect solution. We have been selling punch laser machines since 1979, making us the first manufacturer in this technology. Our portfolio has grown since then, the machines have continuously improved – and you can select the machine that suits you.

The TruMatic 3000 is productive and economical. Outstanding part quality and simple operation in one package.

Outstanding part quality and fully automated material flow – from loading to production to sorting!

The productive high-end machine – combines the advantages of punch laser processing in a particularly cost-efficient way.