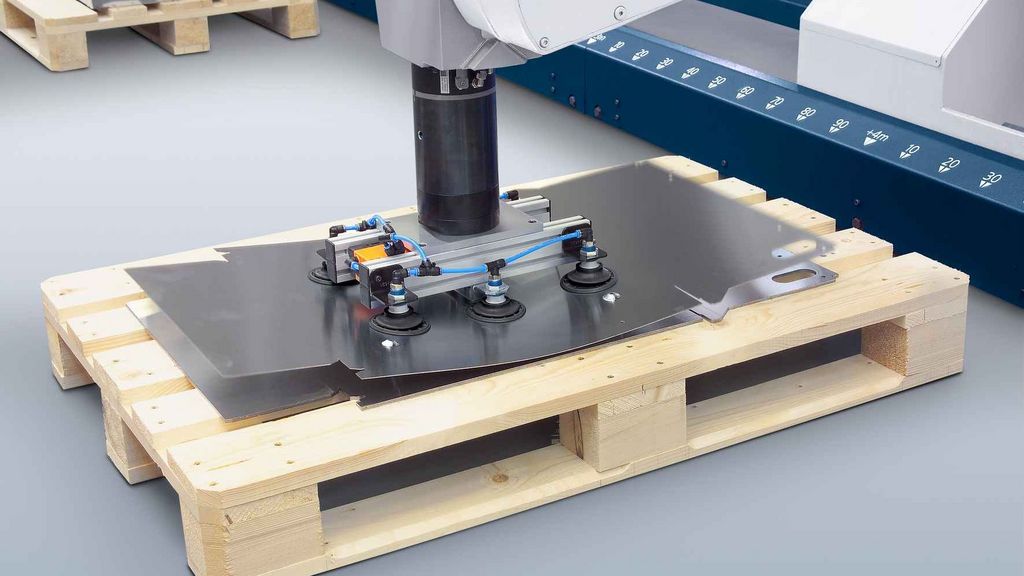

Thanks to innovative gripper technology and handling equipment, the BendMaster can process small and large parts weighing up to 100 kg. With its practical, flexible modular system you can put together the right grippers for your applications.

The advantages of TRUMPF bending machines

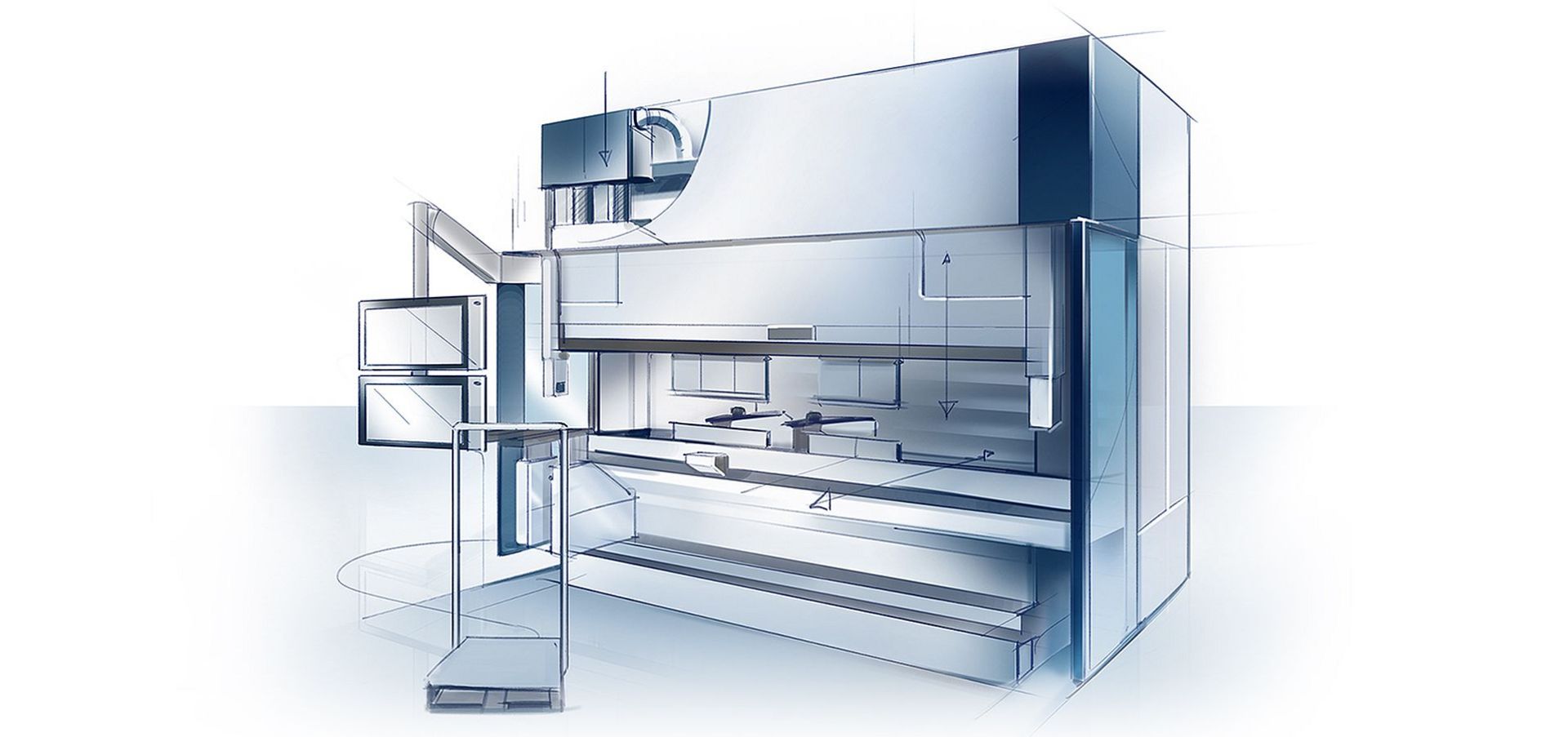

What makes our press brakes so unique?

Think ahead. Bend better: Innovative ideas drive forward bending, and therefore your company's success, too. Modern bending machines and panel benders from TRUMPF impress with functions that save resources, simplify operation and guarantee precision quality – from the very first part. Whether it's laser-measured angles, energy-saving hydraulic systems or fully automated tool changes, this is how to make your bending production even more successful.

1. Automation for all aspects of bending

Small and large components can be reliably produced in multiple shifts. When bending sheet metal automatically, you benefit from very high productivity at low part costs.

Find out more2. Precision and angular accuracy

Precision angles are essential when bending sheet metal. TRUMPF machine concepts and intelligent functions give you precision results every time regardless of the material or workpiece.

Find out more3. Operator support

Bending is physically demanding and finding good benders is often difficult. TRUMPF bending machines are therefore designed to be ergonomic and user-friendly and provide operators with optimum support.

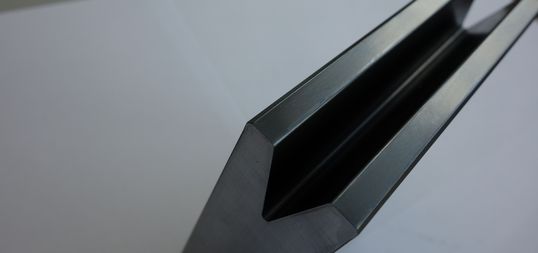

4. Tool variety

The best bending results are achieved by the optimal interaction of all components. Because it has to be genuine to guarantee this, TRUMPF has been manufacturing its own bending tools for over 20 years – in top quality and with the broadest range of tools on the market.

Automation for all aspects of bending

Precision and angular accuracy

Operator support

Tool variety

At TRUMPF, customers get the perfect press brake for every requirement. The bending tool team develops customer-specific tool solutions and thoroughly tests production with the respective material to optimise the production process.

Bending machines from TRUMPF are extremely robust and durable. The unique TRUMPF LaserDur hardening process enables hardening in the HRC 60-62 range. Since local heating is only applied where necessary, operator safety is increased.

The operator's life just got easier: TRUMPF's lightweight tools weigh significantly less than standard bending tools. Yet they remain just as strong.