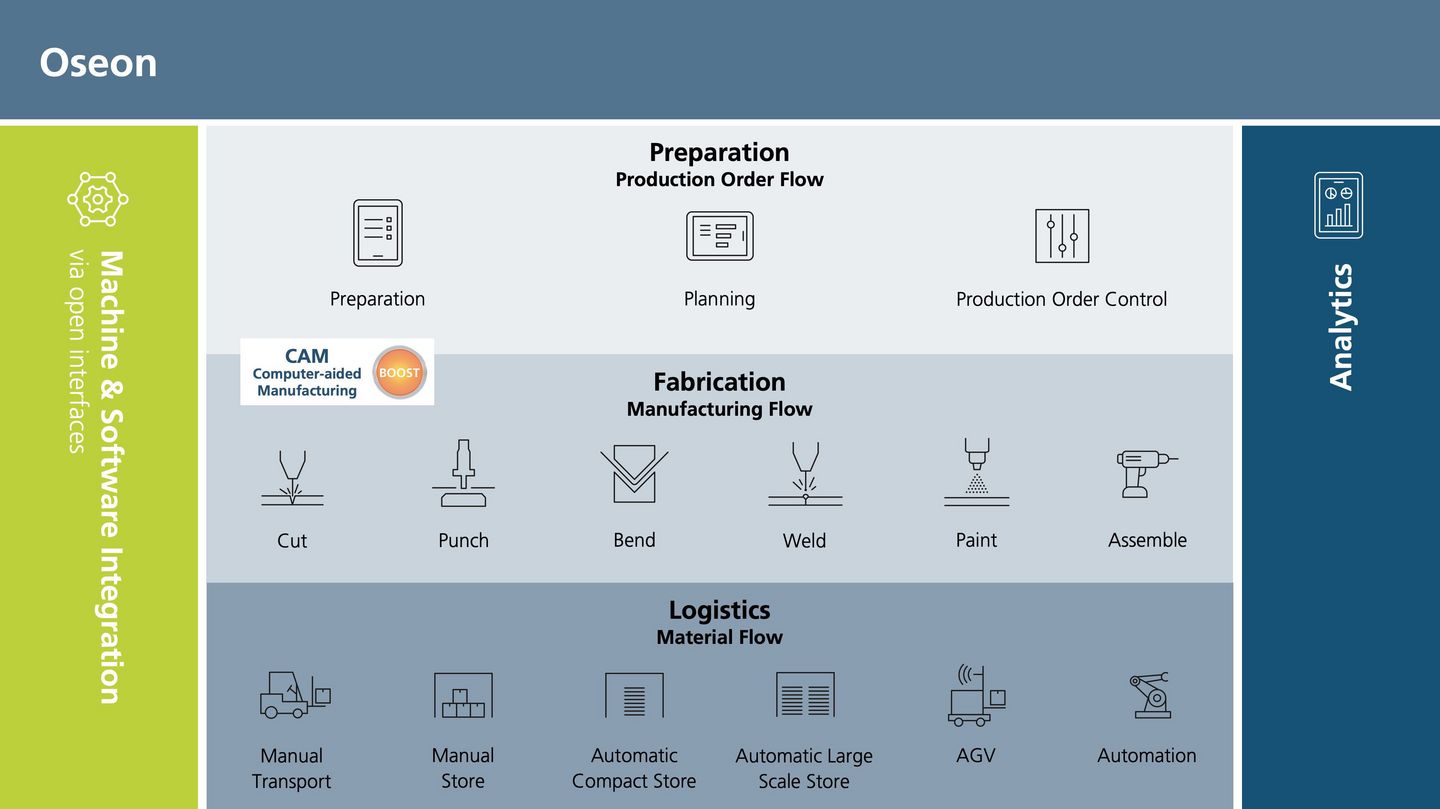

Order preparation processes are integrated in Oseon. Interfaces enable communication with adjacent sections , e.g., programming. You can use the production planning tool to simplify production planning. It provides reliable information on delivery dates, taking into account workstation capacities and the current status of production. Digitally connected with all production employees.

Production control: a perfect production flow with Oseon

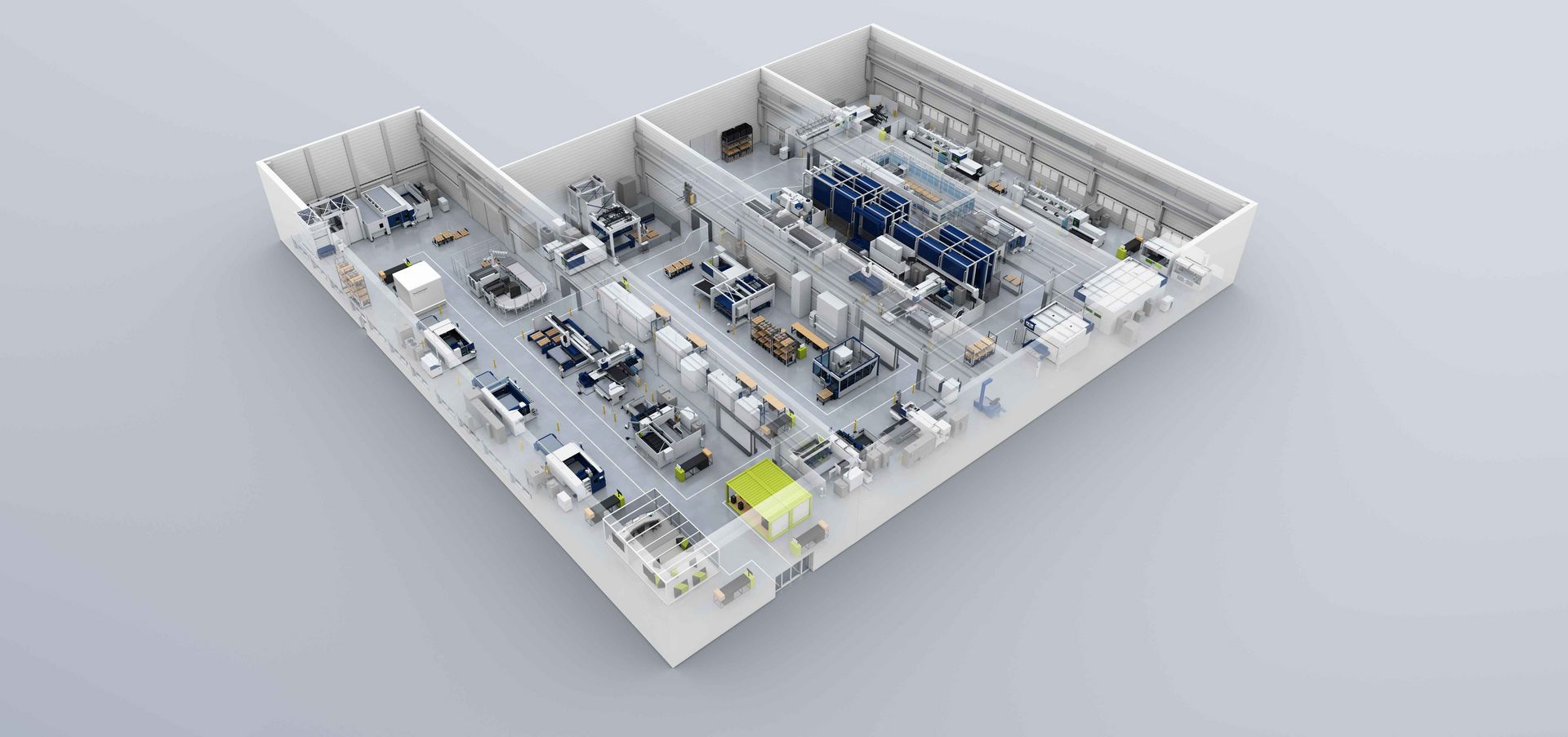

As a sheet metal processor, how do you keep an overview over your processes? With Oseon – a comprehensive solution for production and material flow control, which supports users according to their roles and displays your processes consistently and transparently. This opens up growth and savings potential for you.

Oseon: Work flows

Information is generated at many points in your production. The Oseon software ensures that you receive all relevant information at the correct time and at the correct location, specific to the particular users. To this end, Oseon combines the production control of the sheet metal process chain with the benefits of a logistics system. Standard interfaces ensure simple integration of your existing facilities, automation and systems. The result is a seamless flow of information along the entire production chain. To put it simply: work flows

Oseon Go digitalises all core processes in your production.

Oseon Grow is an extension of Go in the areas of storage, logistics and interfaces.

You achieve a complete network with Oseon Flow.

Oseon Go

Whether a parts spectrum or technologies: no production is static. That is why you need a flexible control solution that not only goes along with permanent changes but also actively supports you in them. With Oseon, your information flow is accessible wherever you are thanks to mobile terminals. The system displays your sheet metal processing with a transparent overview. Following the principle "As much as necessary, as simply as possible", it is easy for users to learn how to use and operate Oseon. Even new employees can quickly learn how to operate it thanks to its role-based structure and guided work steps. Use Oseon Go for your core processes or extend your software with the Grow and Flow packages until you are controlling your entire workflow with this program.

Oseon connects production and the material flow

Most software solutions are separated according to functions, into modules such as "Production" and "Logistics". In sheet metal processing, these roles are often not defined clearly, meaning that production staff also take on logistics tasks. This means users have to tediously switch between modules. Oseon, on the other hand, provides task-specific support – and delivers the correct information to the correct person at the correct time.

Growth requires flexibility – you determine the Oseon scope suitable for your production and scale it as required

The web-based app simplifies your job thanks to step-by-step instructions

Control and monitor your material flow and manage your inventory.

You always have your eye on your production – which is how you achieve maximum tolerance and increase your efficiency

The app accompanies you throughout the working day, provides instructions and supports you with your tasks in a targeted manner

Hit the ground running with Oseon Go

You will digitalise and simplify the core processes of your sheet metal processing with the Oseon Go software package. The software experts from TRUMPF will explain how that can advance your company in a personal consultation.

Oseon Grow

Whether Go, Grow or Flow: the flexibly structured solution meets you exactly where you are. As a sheet metal processor, you can use it to grow step by step and digitalise and automate your production as much as you require at the time.

At the correct place at the correct time

Media gaps and false information can cause some productions to grind to a halt. Oseon digitalises and connects the order and material flow. But above all, it guides users through the working day based on their roles. Staff in the production or store areas see on mobile devices what is currently important for their task. Everyone knows what they need to do. The result: your production flows – and you can respond to customer requests quickly and confidently.

Optimum use of resources and profitable production, even from lot size 1

You always have all the information you need on the shop floor ready to hand in the web-based app

Manage the material, inventory data and transport orders directly on the shop floor

You can keep track of the utilisation of all machines and optimise your production step by step with Oseon

Scheduling production orders taking existing workstation capacities and feedback into consideration.

Would you like your production to grow?

You integrate further processes and automate your material flow with the Oseon Grow software solution package. It might be best to discuss with the software experts from TRUMPF how this can help your company grow.

Oseon Flow

The path is cleared for fully automated sheet metal processing with Oseon Flow.

Fulfil customer requests immediately

The production and material flow control from TRUMPF is easy to learn and operate throughout, even in the Flow expansion stage. It is based on the fundamental idea of relieving staff from the burden of routine tasks and providing them with task-specific support as best as possible. At a corporate level, Oseon helps to ensure production is more cost-effective and customer requests are answered faster.

Optimum use of resources and profitable production, even from lot size 1

You always have all the information you need on the shop floor ready to hand in the web-based app

Manage automated large-scale stores and network the material flow intelligently; including stores and AGVs

You can assess workstations comprehensively, analyse trends and set benchmarks.

Good advice: the flow in your production

With Oseon Flow, you will enhance the interaction between workstations and the material flow in your sheet metal processing, up to complete networking. The objective: a perfect production flow. Talk to your TRUMPF software experts about it.

Oseon Workflow

Oseon Go digitalises all core processes in your production.

Oseon Grow is an extension of Go in the areas of storage, logistics and interfaces.

You achieve a complete network with Oseon Flow.

1. Order preparation

In work preparation, production orders are created quickly and easily or imported via an interface and scheduled for production.

Find out more2. Cutting parts

The web-based app on the tablet provides targeted support to production employees. It displays information relevant to the order and step-by-step instructions.

Find out more3. Sorting

Graphical support on the web-based app simplifies part separation, both directly on the machine and at a separate workstation.

Find out more4. Factory flow

Automatic transport planning and ordering keeps your materials constantly flowing. You can check stock, know exactly where orders are and find out where they are required next .

Find out more5. Bending

With the app, employees at bending machines receive all key information about production orders and bending programmes. Reduced to the essentials and directly at the workstation.

Find out more6. Welding

Oseon also integrates non-networked production systems into the production flow. To do so, the app sends all relevant to the machine operator's tablet.

Find out more7. Threaded bolt welding

With the web-based app, manual workstations are fully integrated. Step-by-step instructions ensure a high level of process reliability, even for inexperienced employees.

Find out more8. Assembly

With Oseon , assembly employees have mobile access to work instructions and drawings. This increases efficiency and process reliability.

Find out more9. Analytics

Oseon Analytics gives you a complete overview of your entire production line at all times with instant malfunction notifications. Comprehensive dashboards ensure a high level of transparency.

Find out moreOrder preparation

Cutting parts

With Oseon, production employees on the shop floor (e.g., operators of 2D laser cutting and punching machines) always have all the important information about their own production to hand. For a transparent overview and better process reliability, all feedback on the order is provided digitally. As a result, paper consumption is reduced to a minimum.

Sorting

The app uses coloured markers to show shop floor workers exactly which parts belong to a production order, assembly or customer order. For even more efficiency, the parts are booked on pallets or containers in the same work step and transport orders are created for the next workstation. This is a major simplification that increases transparency and process reliability.

Factory flow

Manual and automatic transport vehicles are taken into account depending on availability. Logistics employees are informed about transport orders via the web app and are supported in their operations digitally. The seamless interaction increases the efficiency in material flow. Oseon also supports the stock management of manual, automatic or large storage systems - depending on the customer's needs.

Bending

Oseon provides bending programmes suitable for the loaded production orders on the tablet or machine monitor. The availability of the parts to be bent is also displayed with the corresponding priorities . To increase flexibility, the management of bending pools and the assignment of a bending machine are also supported. Processes can be easily booked via the app, bringing transparency to the shop floor.

Welding

The web-based app shows employees all the information relevant to the work order at the respective workstation. Loaded production orders and priorities, drawings, necessary materials - including storage locations and work and safety instructions - are clearly provided. Work progress can be conveniently recorded in the app.

Threaded bolt welding

Oseon holistically connects manual workstations to networked production. As a result, drawings and BOMs can be viewed and material postings and reject messages can be digitally entered at the workstation. Production progress is reported to the system via the app and transport orders are registered for subsequent processes through automatic booking at docking stations.

Assembly

Oseon digitally integrates assembly stations into production. Operator's manuals and 3D drawings provide clear work instructions. The availability of parts from upstream operations that are necessary for the production order are displayed via web app. This eliminates uncertainties. The system is digitally notified when the order is complete by the click of a button.

Analytics

Evaluation options and status messages on machines and workstations enable a consistent and transparent view of your production. Use this information together with your employees for active shop floor management. Together you will achieve shorter production and delivery times and a faster response to customer requests.

New Oseon releases

Find out here what innovations the new release of Oseon has to offer.