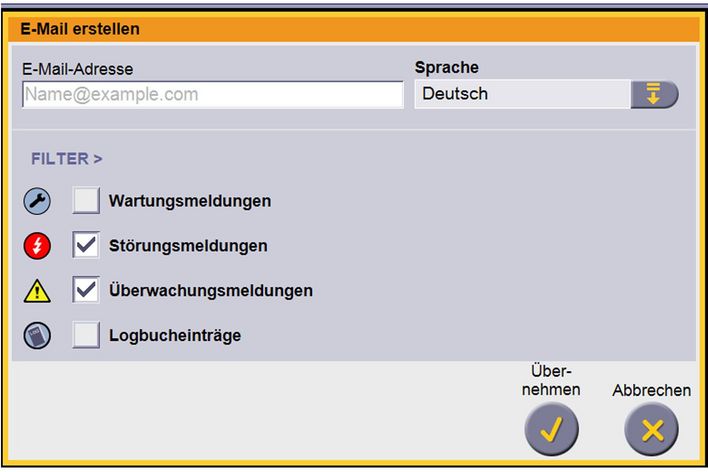

E-mail notification

If there are warnings, errors or malfunctions on the laser device, these are sent by e-mail to pre-defined people or groups. This offers the advantage that important messages, warnings or occurring errors cannot be overlooked or go for long periods without action.